Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPU raw materials:

1. various kinds

2. competitive price

3. 30 years of experience

4. stable quality

TPU raw materials:

1. Applications and cable specifications of TPU raw materials:

Used for water-resistant power cables, data cables, and spring wire.

2. Description of TPU raw materials:

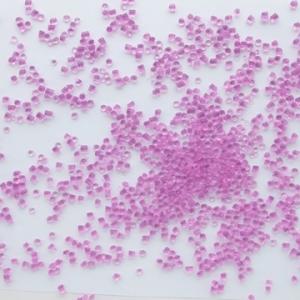

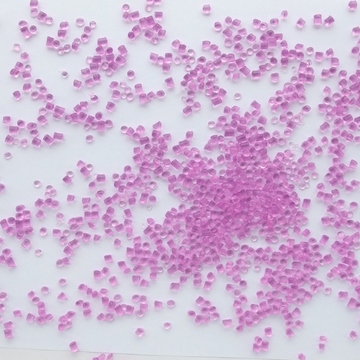

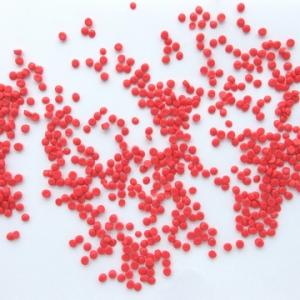

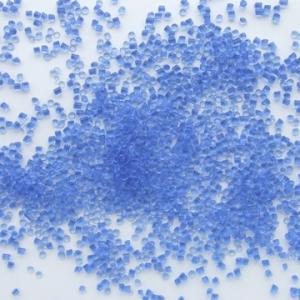

Environmental friendly halogen-free TPU cable compound, based on TPU elastomer resin, is made into granules by mixing, plastification and granulation with adding special modifier and other special additives. It has well performance of tenacity, scratch-resistant, flexibility, Stretch Resistance, and temperature resistance, owning exquisite appearance and smooth surface. It does not contain halogens and heavy metal, in line with the environmental directives of RoHS, REACH. Different hardness can be customized according to customers’ requirements.

3. Processing of TPU raw materials:

The compound can be processed with conventional extruders. It is recommended that the screw L/D should be greater than 25 and compression ratio should be 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

temperature °C | 150 | 170 | 155 | 175 | 178 | 178 | 175 |

Note:Compound should be dried at 80-90°C before use, which has stayed in storage more than one month.

4. Storage and transport of TPU raw materials:

Packaging:25kg/bag,Aluminum foil and PE film bag inside, and PP compound bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties of TPU raw materials:

Item | Unit | E7385 | E8385 | E8685 | E8685F | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.19 | -- | 1.21 | -- | 1.28 | -- | 1.27 |

Hardness | Shore A | -- | 85 | -- | 85 | -- | 85 | -- | 85 |

Tensile Strength | ≥MPa | 18 | 22 | 22 | 28 | 20 | 25 | 20 | 24 |

Elongation at Break | ≥ % | 550 | 700 | 500 | 650 | 500 | 650 | 450 | 600 |

Thermal aging | °C*h | 136°C*168h | 136°C*168h | 121°C*168h | 121°C*168h | ||||

TS retention | ≥ % | 75 | 103 | 75 | 105 | 75 | 104 | 75 | 102 |

EB retention | ≥ % | 75 | 81 | 75 | 84 | 65 | 89 | 65 | 86 |

Hot deformation | 150°C*4h | 150°C*4h | 150°C*4h | 150°C*4h | |||||

Variation on thermal deformation | ≤ % | 50 | 12 | 50 | 7 | 50 | 6 | 50 | 6 |

pH value of gases released | ≥ | 4.3 | 56. | 4.3 | 5.3 | ||||

Conductivity of Gases released | ≤μm/mm | 10 | 1.2 | 10 | 1.3 | ||||

Impact Brittleness Temperature | ≤ °C | -60 | Pass | -55 | Pass | -50 | Pass | -50 | Pass |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 2.1×1013 | 1.0×1013 | 5.2×1014 | 1.0×1013 | 3.4×1014 | 1.0×1013 | 1.8×1014 |

Flame retardant grade | UL94 2mm | V0 | pass | V0 | pass | ||||

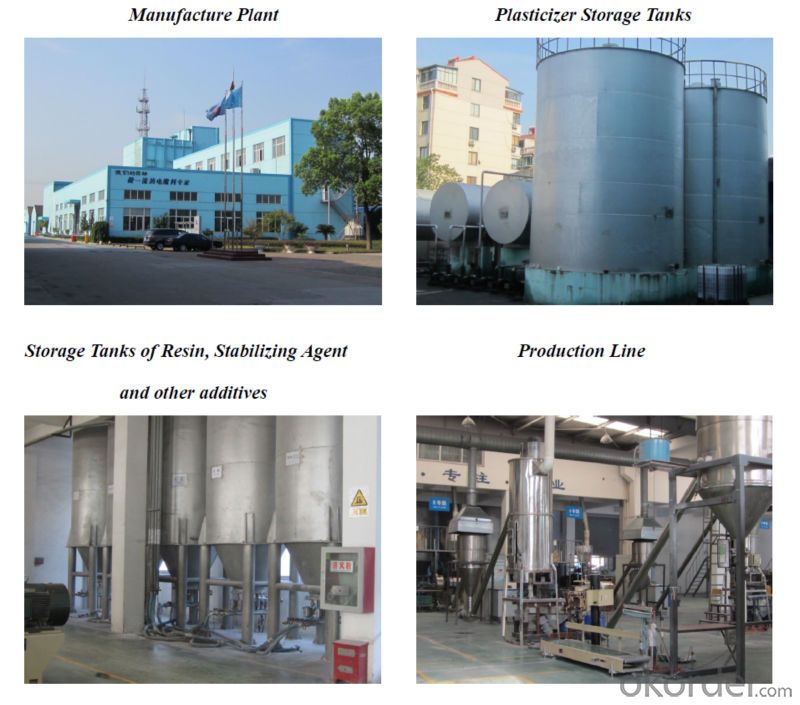

6. Company

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- However, blow ratio can not be too large, otherwise easy to cause the bubble unstable and prone to wrinkle film. Therefore, the blow up ratio should be equal to the traction ratio. Generally speaking, the blow up ratio of low-density polyethylene (LDPE) film should be controlled at 2.5-3.0.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: How to use all kinds of plastic materials?

- GPPS modified polystyrene 204The transparency of 88-92%, refractive index 1.59-1.60, suitable for light products, dyeing is strong, non-toxic and tasteless, no fungus growth, high impact strength, resistance to acid and alkali resistant performance is good, not on the basis of solvent, excellent electrical properties, easy molding, moisture less than 0.02% can maintain the strength and size of high humidity, but the brittleness.Suitable plastic products: decorations, lighting signs, lampshades, stationery, transparent toys, daily necessities, instrument lenses, freezers and thermal insulation in the refrigerator (after foaming).

- Q: Plastic raw materials packaging is generally divided into several categories?

- A variety of kraft paper, polyethylene thick film, fiber bags, aluminum foil bags

- Q: How to make plastic raw materials?

- polyethyleneFor short, PE is a thermoplastic resin made by the polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference. The properties of polyethylene vary depending on the molecular structure and density. The products of different densities (0.91 ~ 0.96g / cm3) can be obtained by different production methods. Polyethylene can be used as a general thermoplastic forming method (see plastic processing). Widely used, it is mainly used for making films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as high frequency insulating materials for television, radar and so on. With the development of petrochemical industry, polyethylene production has been developed rapidly, and the output is about 1/4 of the total plastic output. In 1983, the total production capacity of polyethylene in the world was 24.65Mt, and the capacity of the equipment under construction was 3.16Mt.

- Q: What is plastic material E-PET?

- I'm in the chemical industry.PET is polyester. Never heard of the E PETI doubt if you said that the E-PET E is not an abbreviation for electric, an insulating PET that can be used to make PET electrical insulating films.

- Q: What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- Raw material is crude oil refining, renewable materials are garbage recycling, and some will have additives in the regeneration. If it is not cleaned, there may be impurities.

- Q: What does MFI mean in PC material?

- MFI- melt flow index, also known as the melt flow rate (MFR), it was determined at a given shear stress (with applied load) and temperature, melt flow properties of materials (measured by g/10min).

- Q: How about the price of plastic raw materials now?

- The downstream continues to be on demand, with little change in demand. There is a more detailed analysis of quotations

- Q: What are the materials for making plastic basins? Are they raw materials?

- The plastic washbasin is made of PP plastic(polypropylene is a thermoplastic resin made by the polymerization of propylene.)Is a relatively traditional washbasin, anti wrestling performance is very strong.Although the modern bathroom, a variety of shapes, materials, fashion basin are,But still can not do without this traditional plastic basin.

Send your message to us

Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords