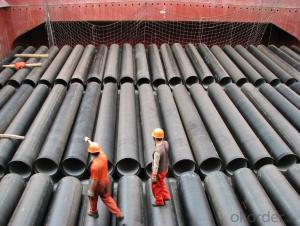

EN545 Ductile Iron Pipe Socket Spigot Pipe K9 DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) The standard of pipe: ISO2531:1998, EN545:2006,K9 K8

2) Effective length: 6m/5.7m

3) Inner cement line: Portland cement lineas per ISO4179

4) Zinc coating: at least 130g/m2 as per ISO8179

5) Bitumen painting: at least 70μm as per ISO8179

6)With 102% quantity of NBR, SBR, or EPDM ring asper ISO4633

7) DN80-DN1200

8) Highstrength, lighter than grey iron, good corrosion resistance, no furring, smallflow resistance, easy fixing, long life tome about 100 yeas

9)Checked by automatic inspection equipment

10) Composition:

Chemical composition | |||

Chemical composition | Ductile Cast Iron Pipe (%) | Grey iron pipe (%) | Steel pipe (%) |

C | 3.5-4.0 | 3.2-3.8 | 0.1-0.2 |

Si | 1.9-2.6 | 1.4-2.2 | 0.15-0.4 |

Mn | 0.15-0.45 | 0.4-0.6 | 0.3-0.6 |

P | ≤0.06 | ≤0.3 | 0.02-0.03 |

S | ≤0.02 | ≤0.1 | 0.02-0.03 |

Mg | 0.03-0.06 |

|

|

11) Feature:

Mechanical properties | |||

| Ductile Cast Iron Pipe | Grey Iron Pipe | Steel Pipe |

Tensile Strength(Mpa) | ≥420 | 150-260 | ≥400 |

Yield Strength(Mpa) | ≥300 | No Confirmation | No Confirmation |

Bending Strength(Mpa) | ≥590 | 200-360 | ≥400 |

Elongation (%) | ≥10 | Neglected | ≥18 |

Brinell Hardness(HBS) | ≤230 | ≤230 | About 140 |

12) T type mechanical joint

13) Packing: in bulk or container

PACKING: 1) Pipesare bundled together with the steel belt.

2) Wooden pieces are put between the pipes.

- Q: Can ductile iron pipes be used for underground fire hydrant systems?

- Yes, ductile iron pipes can be used for underground fire hydrant systems. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them a suitable choice for underground installations. They can withstand the high pressure and flow rates required for fire hydrant systems, ensuring reliable water supply for firefighting purposes.

- Q: Are ductile iron pipes resistant to impact damage?

- Yes, ductile iron pipes are highly resistant to impact damage due to their inherent strength and durability.

- Q: Can ductile iron pipes be used for bridge drainage systems?

- Yes, ductile iron pipes can be used for bridge drainage systems. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for various applications, including bridge drainage systems. They can effectively handle the flow of water and withstand the weight and pressure of vehicles passing over the bridge.

- Q: What are the different types of joints used with ductile iron pipe?

- There are several different types of joints that can be used with ductile iron pipe. These joints are designed to provide a secure and watertight connection between sections of pipe. Some of the most common types of joints used with ductile iron pipe include: 1. Mechanical Joint: This is the most commonly used joint for ductile iron pipe. It consists of a gland and a follower which are tightened using bolts and nuts to provide a tight seal. Mechanical joints are flexible and can accommodate slight misalignments. 2. Push-On Joint: This type of joint does not require any bolts or nuts. It is designed to be easily assembled by simply pushing the pipe sections together. A rubber gasket is used to provide a watertight seal. 3. Restrained Joint: Restrained joints are specifically designed for applications where pipe movement needs to be limited. These joints typically include a mechanical joint with additional features such as thrust collars or tie rods to prevent axial movement. 4. Flanged Joint: Flanged joints are commonly used for larger diameter pipes. The pipe ends are flanged and then bolted together, with a gasket placed in between to create a leak-proof connection. Flanged joints are typically used in applications where frequent disassembly and reassembly may be required. 5. Welded Joint: In some cases, ductile iron pipe sections may be welded together using a fusion welding process. This creates a permanent and strong joint. Welded joints are commonly used in high-pressure applications where a reliable and durable connection is required. It is important to note that the choice of joint type will depend on the specific requirements of the project, such as the pipe diameter, pressure rating, and the nature of the fluid being transported. Additionally, local regulations and standards may also dictate the type of joint that should be used in certain applications.

- Q: What does ductile iron pipe "K" mean?

- K means wall thickness registration, general water supply and drainage, now China uses K9, and some countries in South America, such as Brazil, use K7.The wall is thick =k (DN/1000+0.5), such as K9's DN500 tube, with a wall thickness of =9* (500/1000+0.5) =9mm

- Q: How do ductile iron pipes handle soil erosion?

- Ductile iron pipes are highly resistant to soil erosion due to their robust construction and inherent strength. The pipes' durable and flexible nature allows them to withstand the impact of soil movement and erosion without significant damage. Moreover, the corrosion-resistant coatings applied to ductile iron pipes further enhance their ability to resist erosion caused by soil particles and other corrosive elements. Overall, ductile iron pipes provide a reliable and long-lasting solution for handling soil erosion in various applications.

- Q: Are ductile iron pipes suitable for sewer force mains?

- Yes, ductile iron pipes are suitable for sewer force mains. Ductile iron is a type of cast iron that has a higher level of strength and flexibility compared to traditional cast iron pipes. This makes it ideal for applications where the pipes need to withstand high pressure and heavy loads, such as sewer force mains. Ductile iron pipes have excellent resistance to corrosion and are highly durable, which is crucial for sewer systems that are exposed to various corrosive substances and harsh environments. They also have the ability to absorb vibrations and shocks, reducing the risk of pipe failures caused by external forces. Furthermore, ductile iron pipes are known for their long service life, often lasting for more than 100 years. This makes them a cost-effective choice for sewer force mains, as they require minimal maintenance and replacement over their lifetime. Overall, ductile iron pipes offer a reliable and durable solution for sewer force mains, providing the necessary strength, flexibility, and resistance to corrosion to ensure efficient and long-lasting sewer systems.

- Q: Can ductile iron pipes be used for rainwater harvesting systems?

- Certainly, rainwater harvesting systems can utilize ductile iron pipes. Renowned for their robustness and resilience, ductile iron pipes prove to be fitting for a range of purposes, including rainwater harvesting. These pipes exhibit exceptional resistance to corrosion and are capable of withstanding considerable pressure, thereby ensuring the efficient conveyance of rainwater from the point of collection to storage tanks or distribution networks. Moreover, their impressively long lifespan diminishes the necessity for frequent replacements, rendering them a cost-effective option for rainwater harvesting systems.

- Q: Are ductile iron pipes resistant to UV radiation?

- No, ductile iron pipes are not resistant to UV radiation.

- Q: Do ductile iron pipes require external protection against stray electrical currents?

- Yes, ductile iron pipes do require external protection against stray electrical currents. Stray electrical currents can cause corrosion to the pipe, leading to premature failure and potential leaks. To protect against this, external coatings or wraps are applied to the ductile iron pipes to provide a barrier between the pipe and the electrical currents. This protection helps to ensure the longevity and reliability of the pipes, preventing costly repairs and potential safety hazards.

Send your message to us

EN545 Ductile Iron Pipe Socket Spigot Pipe K9 DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords