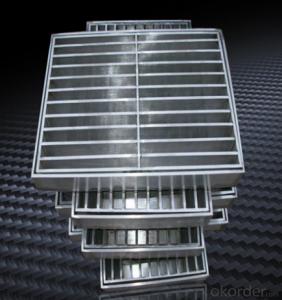

EN124 High Quality Sewage Ductile Iron Manhole CoveR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

15.Size: Customer's Request

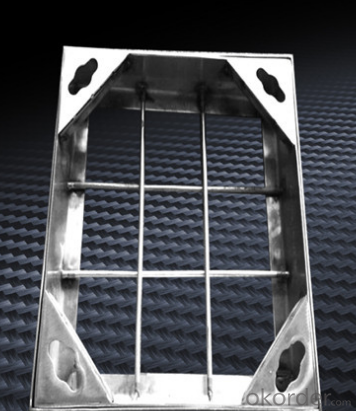

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

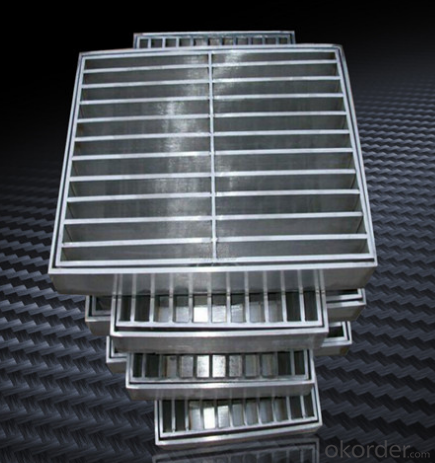

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

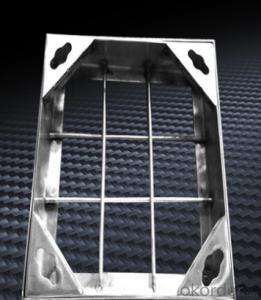

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

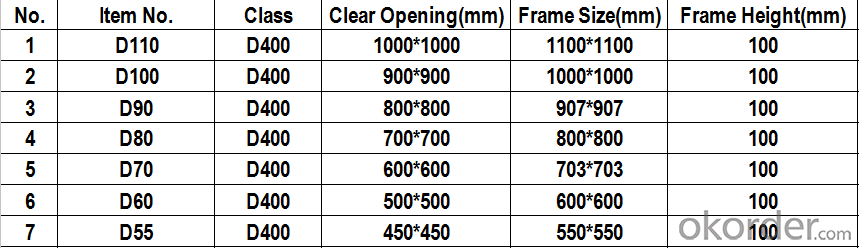

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The first to ask, such as casting end cover, bed and other products, is to put the iron melting and casting againThe two question, their casting castings manufacturers than to buy professional casting factory production, production quality more security professional.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q: How to cast iron and wrought iron collocation

- So we can only watch and ear distinction: 1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron pig iron is bright; the fracture is generally irregular, because it is very brittle, mostly is interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat; if the fracture is that is cutting, wrought iron, iron is not cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity It doesn't have to be so deformed, it's really bent, or it's broken, or it's obviously cracked, and it doesn't bend very much. There are some details that can not be made clear. It is necessary to have some experience.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

Send your message to us

EN124 High Quality Sewage Ductile Iron Manhole CoveR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches