Cheap Aluminum Sheets - EN AW-3003 Aluminium Sheet for Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 3003 Aluminium Sheet for Circles Description

EN AW - 3003 Aluminium Sheet for Circles is one semi-finished aluminium material. The alloy AA3003 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 3003 Aluminium Sheet for Circles

EN AW - 3003 Aluminium Sheet for Circles | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 3003 Aluminium Sheet for Circles

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 3003 Aluminium Sheet for Circles

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 3003 Aluminium Sheet for Circles

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

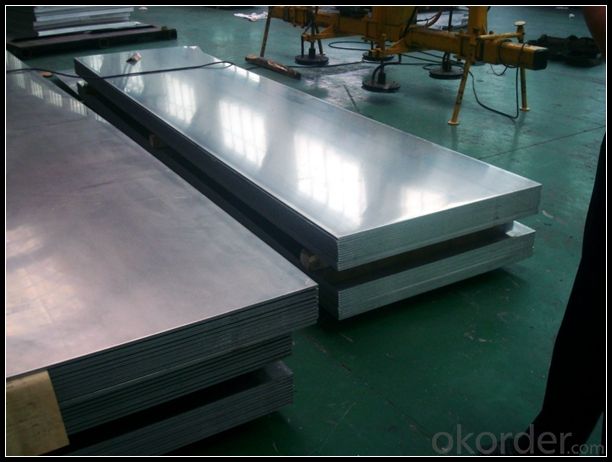

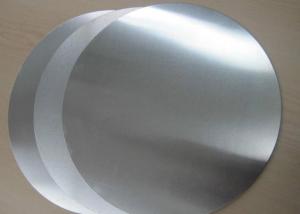

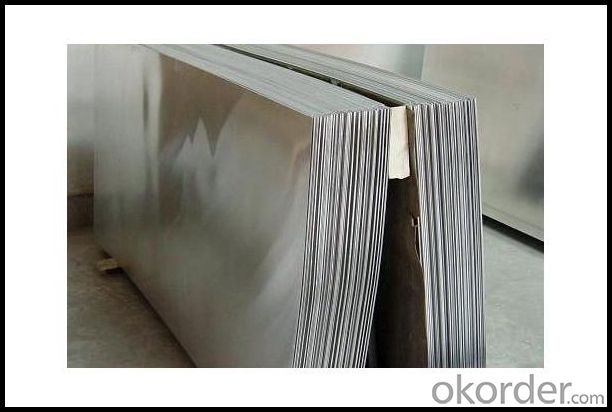

6. Image of EN AW - 3003 Aluminium Sheet for Circles

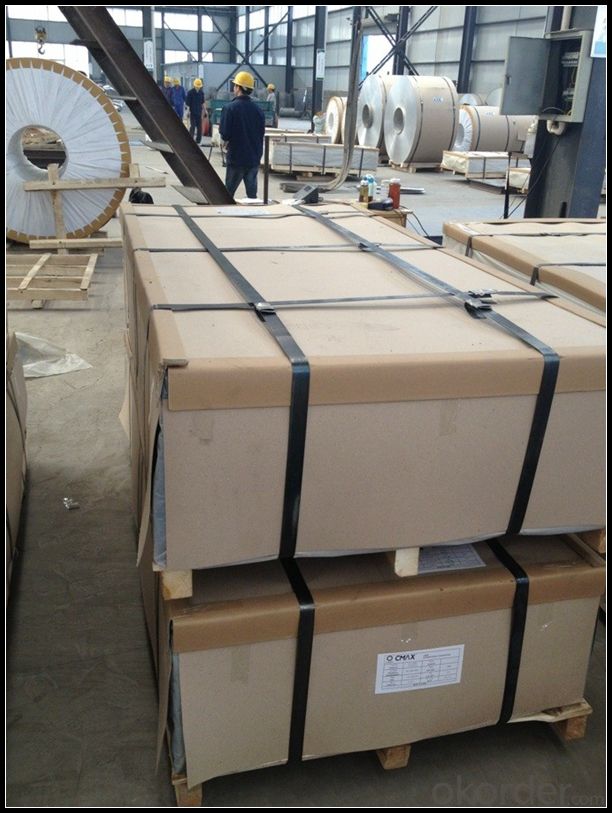

7. Package and shipping of EN AW - 3003 Aluminium Sheet for Circles

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- length * width * thickness = volume (with some unit conversions) Mass = volume * density (look up the density of aluminum) convert mass to moles. convert moles to atoms Divide the cost by the number of Al atoms.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Indeed, aluminum sheets are exceptionally well-suited for the production of lightweight structures. Renowned for its low density, aluminum stands as one of the most lightweight metals on the market. This attribute renders aluminum sheets an exceptional option for a multitude of sectors that prioritize weight reduction, such as aerospace, automotive, and construction industries. Furthermore, aluminum boasts an impressive strength-to-weight ratio, enabling it to withstand substantial loads while remaining lightweight. Moreover, aluminum sheets exhibit exceptional corrosion resistance, rendering them suitable for both outdoor and marine applications. All in all, the combination of its lightness, strength, and durability positions aluminum sheets as the preferred choice for the production of lightweight structures.

- Q: Can the aluminum sheets be used for insulation purposes?

- Aluminum sheets have the ability to serve as insulation material. Due to its high thermal conductivity, aluminum can effectively hinder the transmission of heat between two surfaces. For instance, aluminum sheets can be utilized as a reflective shield within walls, roofs, or floors to minimize heat transfer by reflecting radiant heat. They can also act as a vapor barrier, preventing the ingress or escape of moisture in a given space. Furthermore, aluminum sheets can be incorporated into an insulation system, combining them with other insulating materials like foam or fiberglass to augment their thermal insulation properties. In conclusion, aluminum sheets deliver efficient insulation and contribute to energy efficiency in buildings.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Unless the surface was specially prepared the aluminum won't bond to the steel. To be sure it doesn't, simply 'smoke ' the steel with a candle etc. (thin layer of carbon black), to ensure no bonding. Your problem will come from the different co-efficients of expansion. The aluminum will shrink more than the steel in cooling and will grab that rod very tightly. Your hole, ( therefore your rod), will have to have a considerable taper if you ever hope to drive that rod out of the casting. Caution- You are aware that most aluminum alloys will burn in air at pouring temperatures aren't you?

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that adds a protective oxide layer to the surface of aluminum, enhancing its durability and corrosion resistance. During the anodizing process, the aluminum sheet is immersed in an electrolytic solution and an electrical current is passed through it. This causes a controlled oxidation of the aluminum surface, creating a porous layer that can be dyed to achieve custom colors. By carefully selecting the dye, different shades and hues can be achieved, allowing for a wide range of custom color options. Additionally, anodized aluminum sheets can also be further processed with techniques such as laser engraving or printing to create unique designs and patterns, making them a versatile choice for various applications in industries like architecture, automotive, and electronics.

- Q: What is the density of aluminum sheets?

- The density of aluminum sheets is subject to variation based on the particular alloy and thickness of the sheet. On average, aluminum sheets have a density ranging from 2.6 to 2.8 grams per cubic centimeter (g/cm³). It is worth mentioning that this figure may undergo slight modifications as a result of the precise manufacturing process and any additional coatings or treatments administered to the sheets.

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: What is the typical thermal conductivity of aluminum sheets?

- The typical thermal conductivity of aluminum sheets is around 205-250 W/m·K.

Send your message to us

Cheap Aluminum Sheets - EN AW-3003 Aluminium Sheet for Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords