Empty Aerosol Spray Can For Hair Care, 57mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: hair spray

Size: 57X260mm

Printing: CMYK printing as Per Customer Design

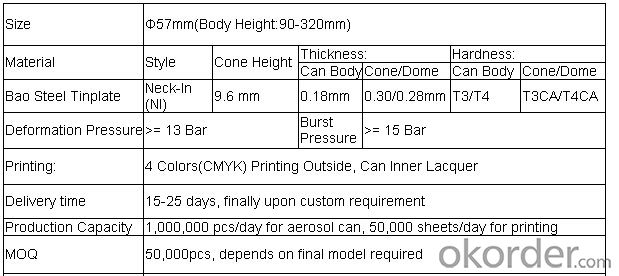

2.Detailed Specification

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

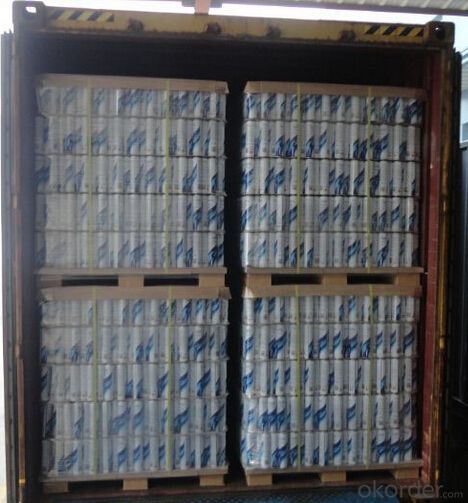

4.Packing

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: How long does tinplate last?

- Tinplate can last for several decades if properly maintained and protected from corrosion.

- Q: How is tinplate coated for automotive components?

- Tinplate for automotive components is typically coated through a process known as electroplating. In this method, a thin layer of tin is deposited onto the surface of the steel substrate through an electrochemical reaction. This coating provides protection against corrosion and also enhances the aesthetic appearance of the automotive components.

- Q: Soup with tin cans loaded also need high temperature sterilization?

- If you are a start-up factory, you need to save money, you can choose a small sterilization pot, covering an area of small, heat source is also very good solution.

- Q: How can tinplate be identified?

- If the food is ready to eat food grade, dressed in non food is to chemical grade on it.

- Q: How does tinplate perform in high humidity environments?

- Tinplate performs well in high humidity environments due to its exceptional corrosion resistance properties. The tin coating on tinplate acts as a protective barrier against moisture, preventing the underlying steel from rusting or corroding. This makes tinplate a reliable and durable option for packaging and other applications in high humidity conditions.

- Q: Can tinplate be used for packaging petrochemical products?

- Yes, tinplate can be used for packaging petrochemical products.

- Q: How does tinplate packaging contribute to product reusability?

- Tinplate packaging contributes to product reusability by providing a durable and long-lasting container that can be reused multiple times. Its sturdy construction ensures that the packaging remains intact even after repeated use, making it ideal for storing and transporting various products. Additionally, tinplate packaging can be easily cleaned and sanitized, allowing it to be used for different purposes without compromising the quality of the contents. This reusability reduces the need for single-use packaging materials, thus minimizing waste and environmental impact.

- Q: What's the advantage of metal containers in packing tea?

- General metal cans are divided into three kinds of tinplate (also known as: tin iron) tin cans, aluminum cans

- Q: What details should I pay attention to when purchasing tinplate packing boxes?

- At present, many domestic buyers can in the face of supplier's first bid, don't know in the condition of love at bargain, or fixed price cut 20 percent off. This practice is very inappropriate, in the procurement of bargain is necessary, but have not thought about the hidden dangers after bargaining?.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides by immersing the steel sheet in a bath of molten tin. This process, known as hot-dipping, ensures that both sides of the steel sheet are evenly coated with a layer of tin, providing protection against corrosion and enhancing its appearance.

Send your message to us

Empty Aerosol Spray Can For Hair Care, 57mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords