Spray Anti-Rust Empty Can Aerosol Can, 52mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief description

Content: insecticide

Size: 52X195mm

Printing: CMYK printing as Per Customer Design

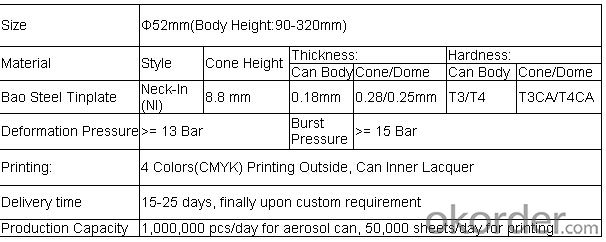

2.Detailed Specification

3. Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4. Package:

5. Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s request

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: Can tinplate be used for packaging liquid products?

- Yes, tinplate can be used for packaging liquid products. Tinplate is highly resistant to corrosion and can effectively protect the contents from external elements. It is commonly used for packaging liquid products such as beverages, oils, and chemicals due to its durability and ability to maintain product integrity.

- Q: Can tinplate packaging be used for kitchen utensils?

- Yes, tinplate packaging can be used for kitchen utensils. Tinplate is a durable material that is resistant to corrosion and has good thermal conductivity, making it suitable for various kitchen utensils such as cans, containers, and even cookware.

- Q: Can tinplate be shielded?

- Two kinds of materials of tinplate and paktong in general: tinplate is cheaper, weldability is good, but easy to rust, and relatively soft, compared to a large shield narrow cover will have problems. Alpaka relatively high prices, the weldability is poor, but can provide performance through tin, relativelyhard. At present, the use of shielding in the mobile phone, these two materials are more, but taking into account the cost or priority of tinplate

- Q: How does tinplate perform in terms of moisture resistance?

- Tinplate performs exceptionally well in terms of moisture resistance. The tin coating on the surface acts as a protective barrier, preventing moisture from coming into contact with the underlying metal. This makes tinplate highly resistant to corrosion and oxidation caused by moisture, ensuring the product's durability and longevity.

- Q: Can tinplate be used for HVAC systems?

- Yes, tinplate can be used for HVAC systems. Tinplate is a durable and corrosion-resistant material that is commonly used in the construction of air ducts and HVAC components. It provides excellent protection against moisture and maintains the integrity of the system, making it a suitable choice for HVAC applications.

- Q: Can tinplate be used for packaging products with specific storage requirements?

- Yes, tinplate can be used for packaging products with specific storage requirements. Tinplate is known for its excellent protective properties, including resistance to moisture, oxygen, and light, which makes it suitable for preserving the quality and freshness of various products. Additionally, tinplate is highly durable and can withstand temperature variations, making it ideal for packaging products with specific storage needs.

- Q: Can tinplate packaging be used for aerosol products?

- Yes, tinplate packaging can be used for aerosol products. Tinplate is a commonly used material for producing aerosol cans due to its strength, durability, and resistance to corrosion. It provides an efficient barrier against moisture and oxygen, which helps to maintain the quality and shelf life of the aerosol product inside. Additionally, tinplate packaging is easily recyclable, making it an environmentally friendly choice for aerosol products.

- Q: How does tinplate affect the cost of packaging?

- Tinplate can increase the cost of packaging due to its higher manufacturing and material expenses compared to other packaging materials such as aluminum or plastic. However, it offers various benefits like excellent durability, corrosion resistance, and ability to keep the contents fresh, which can justify the higher cost for certain products.

- Q: Can tinplate be used for packaging chemicals?

- Yes, tinplate can be used for packaging chemicals. It is a commonly used material for packaging due to its durability, resistance to corrosion, and ability to protect against light and oxygen. Tinplate is also known for its ability to withstand various temperatures and pressures, making it suitable for storing and transporting a wide range of chemicals safely.

- Q: Can tinplate be used for tobacco packaging?

- Yes, tinplate can be used for tobacco packaging. It is a commonly used material due to its durability, ability to preserve the product's freshness, and its ability to protect against moisture and external factors. Additionally, tinplate can be easily decorated and customized to create attractive packaging designs for tobacco products.

Send your message to us

Spray Anti-Rust Empty Can Aerosol Can, 52mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords