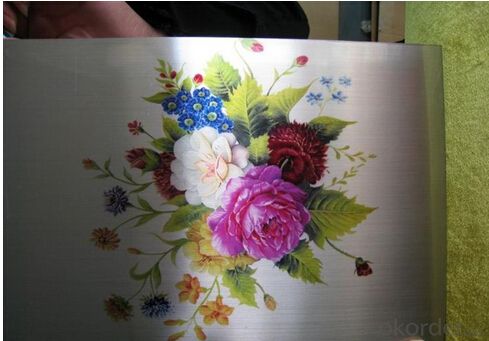

Printed sheet for tea cans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main producers in Chinafor tinplate. At present, ourproductivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

Packaging Detail: For coils: Antirust paper +metal cover +corner protected +woodskid Laded into 20 feet container with max weight 25 tons;For sheets: Thinplastic film +rustproof paper +metal cover +metal angles + straps + pallet.Loaded in 20 feet container with weight 25 tons.

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, cleanenvironment to harvest the trust of the community, safety and health toconvince employees and energy-saving to be trusted by public". We areenjoying the trust and good name regarding to the superior quality and preferservice among the customers. Our products are sold nearly 150 enterprisesincluding Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Ourcommitment: ready to accept advice and customer complaints, reply commentswithin 24 hours of treatment, when dealing with customer complaints of qualityissues, upon customer’s request, sent the inspector to the user site to saveproblem within 24 hours (within the province) and 48 hours (other provinces).

- Q: How to test the tightness of tin metal cans?

- The empty tank which has been cleaned can be dried by 35, and the pressure or pressure leak test shall be carried out according to the equipment condition of each unit. B.1 pressure leak test, the empty tank will be carefully injected into the water until eight or nine into full, the rubber ring will be placed in the appropriate plexiglass plate at the opening side of the roll, so that it can be sealed. Start the vacuum pump, turn off the bleeder valve, hold down the cover by hand, control the pumping, and make the vacuum gauge rise from 0Pa to 6.8X10 PA (510mmHg) for more than 1min, and keep the vacuum above 1min.

- Q: What are the different ways to seal tinplate containers?

- There are several different ways to seal tinplate containers, including using a metal lid with a rubber gasket, using a plastic or paper lid with a heat-sealed lining, using a twist-off cap with a tamper-evident seal, and using a peel-off foil seal.

- Q: What are the printing options for tinplate?

- The printing options for tinplate include lithography, screen printing, and digital printing.

- Q: How does tinplate contribute to the reduction of carbon emissions?

- Tinplate contributes to the reduction of carbon emissions through its recyclability and lightweight nature. As tinplate is made from steel, it can be easily recycled, reducing the need for new production and saving energy. Additionally, tinplate's lightweight properties make it more fuel-efficient during transportation, resulting in lower carbon emissions throughout its lifecycle.

- Q: How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition by providing a protective coating that prevents corrosion and oxidation of the metal components, ensuring the ammunition remains reliable and functional. The tin coating also reduces friction and assists in smooth feeding and extraction, enhancing the overall performance and reliability of the ammunition in firearms.

- Q: How does tinplate impact the overall product safety?

- Tinplate greatly enhances the overall product safety as it acts as a protective barrier against contamination, corrosion, and damage. It safeguards food and beverages from harmful substances, prevents the migration of metals into the contents, and preserves the product's freshness and quality. Additionally, tinplate's durability and resistance to mechanical stress ensure that the packaging remains intact, minimizing the risk of product spoilage or injury to consumers.

- Q: What are the different ways to seal tinplate cans?

- There are several methods to seal tinplate cans. Some common ways include double seaming, soldering, welding, adhesive bonding, and using plastic or metal caps with sealing compounds. Each method has its own advantages and is chosen based on factors such as the type of product being packaged, desired shelf life, cost, and production requirements.

- Q: How do you clean the dust and trace oil on tin containers?

- Solvent cleaning: This is the traditional way, from the middle of the Qing Dynasty period have been used, it is with a cleaning agent such as solvent, steam coal, white oil (to waterlogging, water purifier, hydrocarbon and so on).

- Q: What are the typical tooling costs for tinplate production?

- The typical tooling costs for tinplate production vary depending on factors such as the complexity of the design, size of the production run, and specific requirements. However, tooling costs for tinplate production can range from a few thousand dollars to tens of thousands of dollars.

- Q: How does tinplate compare to aluminum packaging in terms of cost?

- In terms of cost, tinplate tends to be more affordable compared to aluminum packaging.

Send your message to us

Printed sheet for tea cans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords