Aerosol Can for Hair Spray,Φ57mm Tinplate Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 100000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: hair spray

Size: 57X260mm

Printing: CMYK printing as Per Customer Design

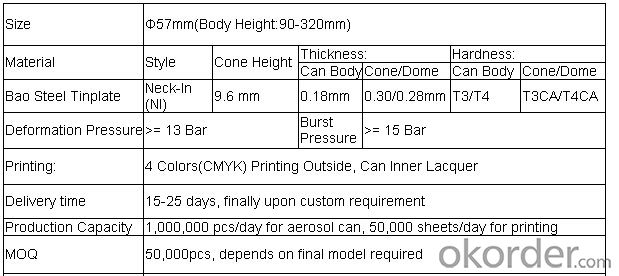

2.Detailed Specification

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Packing

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What's the difference between iron, aluminium, stainless steel, galvanized iron and tin?

- Iron is another kind of material. It is easy to be oxidized (embroidered) when it meets waterGalvanized sheet is made of iron, but zinc is plated on the surface to improve oxidation resistance. The price is cheap

- Q: What are the advantages of using tinplate for paint cans?

- There are several advantages of using tinplate for paint cans. Firstly, tinplate is highly resistant to corrosion, ensuring that the paint cans remain durable and do not rust over time. Secondly, tinplate has excellent sealing properties, preventing any leakage or evaporation of the paint. Additionally, tinplate is lightweight and easy to handle, making it convenient for transportation and storage. Lastly, tinplate is a sustainable choice as it is recyclable, contributing to environmental conservation efforts.

- Q: What are the characteristics of different tin process

- Good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package. 2.: excellent barrier tin barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: What are the main safety regulations for tinplate production and use?

- The main safety regulations for tinplate production and use include ensuring proper ventilation and extraction systems to prevent inhalation of fumes, providing personal protective equipment such as gloves and goggles to protect workers, implementing fire safety measures such as fire extinguishers and sprinkler systems, maintaining machinery and equipment in safe working condition, conducting regular safety training for employees, and complying with local and national regulations regarding hazardous materials handling and waste disposal.

- Q: Can tinplate be used for chemical storage containers?

- Yes, tinplate can be used for chemical storage containers. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent resistance against corrosion. This makes it suitable for storing various chemicals, as it helps to prevent any reaction between the stored substance and the container. Additionally, tinplate is durable and has good strength, making it a reliable option for chemical storage.

- Q: Can tinplate be painted?

- Yes, tinplate can be painted. Tinplate is commonly used in the production of cans and other packaging materials, and it is suitable for various coating processes, including painting. The surface of tinplate can be treated and primed before applying paint, ensuring good adhesion and durability of the painted finish.

- Q: Can tinplate be used for microwave-safe packaging?

- No, tinplate cannot be used for microwave-safe packaging as it is a metal material that can cause sparks and potential hazards in the microwave.

- Q: What are the main challenges in tinplate supply chain management?

- The main challenges in tinplate supply chain management include ensuring a steady and reliable supply of tinplate, managing fluctuations in demand and supply, coordinating multiple stakeholders in the supply chain, optimizing transportation and logistics, ensuring product quality and compliance with regulations, and mitigating risks such as price volatility and disruptions in the supply chain.

- Q: Can tinplate be used for packaging soups and broths?

- Yes, tinplate can be used for packaging soups and broths. Tinplate is a commonly used material in food packaging due to its durability, ability to maintain product freshness, and resistance to corrosion. It provides a reliable barrier against moisture and oxygen, making it suitable for preserving the quality and taste of soups and broths. Additionally, tinplate cans are easy to open and can be safely heated, making them convenient for consumers.

- Q: How does tinplate contribute to the safety of toys?

- Tinplate contributes to the safety of toys by providing a durable and non-toxic material that is resistant to corrosion and can withstand rough handling. It helps prevent sharp edges and ensures that toys do not break easily, reducing the risk of injuries during play. Additionally, tinplate is often used in the packaging of toys, offering a protective barrier that prevents contamination and prolongs the shelf life of the product.

Send your message to us

Aerosol Can for Hair Spray,Φ57mm Tinplate Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 100000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords