Tinplate For Aerosol Can-CFX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

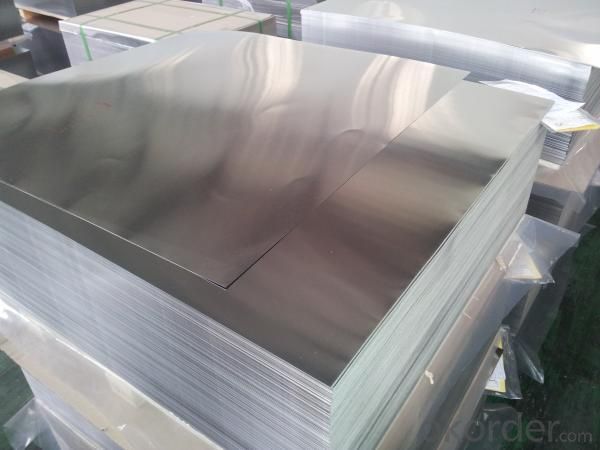

General information of Tinplate For Aerosol Can

|

Steel Type |

SPCC |

|

Temper (BA&CA) |

T1~T5, DR8 |

|

Coating |

2.8~8.4g/m2 |

|

Thickness & Tolerance |

0.15~0.5mm (Tolerance:±0.01mm) |

|

Width & Tolerance |

600~1000 mm(Tolerance: +2/-0mm) |

|

I.D |

508 MM |

|

Coil Weight |

3~10 MT |

|

Passivation |

311 |

|

Oiling |

DOS |

|

Surface Finish |

Bright ,Stone ,Silver ,Matte |

|

Min Order |

25 Tons for 1 20 feet FCL |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Standard Available |

GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

|

Lead Time |

35 days after receiving buyer's original L/C or Prepayment |

|

Special specifications are available on customers' requirements. | |

Technical data of Tinplate For Aerosol Can

|

Chemical Composition(%) |

Mechanical Property |

|

C:0.04~0.06 |

Yield Strength: (Mpa):280~320 |

|

Si:0.01~0.03 |

TensileStrength: (Mpa):340~390 |

|

Mn:0.18~0.22 |

Elongation:20%~30% |

|

P:0.014~0.016 |

------------- |

|

S:0.006~0.009 |

Applications of Tinplate For Aerosol Can

Tinplate is widely used for making all types of containers such as artistic cans, tea cans,

painting cans, chemical package cans and metal printing etc. Its applications are

not limited to containers; recently, tinplate has also been used for making

electrical machinery parts and many other products.

Equipment and Facility

Tin Coating Line

Cold Rolling Mill Batch Annealing Furnaces

Cutting Line Stock Area

Quantity Control System

- Q: What are the different coating options for tinplate?

- Some different coating options for tinplate include tin-free steel (TFS), electrolytic tinplate (ETP), tin-free steel with lacquer, and organic coatings such as epoxy or polyester. These coatings provide various levels of corrosion resistance and can be chosen based on the specific requirements of the application.

- Q: How does tinplate handle exposure to light?

- Tinplate is not affected by exposure to light, as it is a durable material that does not undergo any chemical changes or degradation when exposed to light.

- Q: How does tinplate contribute to the functionality of household goods?

- Tinplate contributes to the functionality of household goods by providing a durable and protective coating that prevents corrosion and preserves the quality of the product. Its ability to resist moisture and maintain food freshness makes it ideal for packaging food items such as canned goods. Additionally, tinplate's versatility allows it to be easily formed into different shapes, enabling the creation of various household items like containers, kitchen utensils, and decorative pieces.

- Q: How does tinplate packaging impact brand image and perception?

- Tinplate packaging can have a positive impact on brand image and perception. Its durability and premium appearance can enhance the perception of the brand, conveying a sense of quality and sophistication. Additionally, the ability to customize tinplate packaging with unique designs and finishes can help brands differentiate themselves and create a memorable impression on consumers. Overall, tinplate packaging can contribute to a positive brand image, reinforcing the brand's values and attracting customers.

- Q: What are the main competitors of tinplate in the packaging industry?

- The main competitors of tinplate in the packaging industry include aluminum, plastic, and glass.

- Q: Can tinplate be used for packaging of organic products?

- Yes, tinplate can be used for packaging of organic products. Tinplate is a durable and non-reactive material that provides a protective barrier against external elements, ensuring the freshness and integrity of organic products. Additionally, tinplate is recyclable, making it an environmentally friendly choice for packaging organic products.

- Q: Can tinplate be used for packaging of flammable liquids?

- No, tinplate is not suitable for packaging flammable liquids as it is not resistant to corrosion and may react with the liquid, potentially causing leaks or fire hazards.

- Q: How does tinplate perform in terms of tamper resistance?

- Tinplate performs well in terms of tamper resistance due to its strong and durable nature. It is difficult to manipulate or tamper with, providing a secure packaging solution for various products.

- Q: What are the main export markets for tinplate?

- The main export markets for tinplate include countries such as China, Japan, South Korea, United States, and Germany.

- Q: What are the main differences between tinplate and tinplate laminates in terms of shelf life?

- Tinplate has a longer shelf life compared to tinplate laminates. Tinplate is made of a single layer of tin coating on steel, providing excellent corrosion resistance and protection against oxygen and moisture. Tinplate laminates, on the other hand, consist of multiple layers, with a thin layer of tin on top of a substrate material such as plastic or paper. While laminates can offer additional features like flexibility and printability, they may have a shorter shelf life due to the potential for delamination or degradation of the substrate material.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Singapore;Belgium |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 240,000 square meters |

| No. of Production Lines | Above 11 |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

Tinplate For Aerosol Can-CFX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords