Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

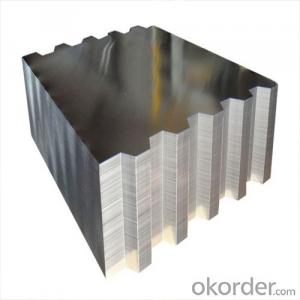

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm: Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm:The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm:From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

Specification of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm:

Standard: GB/T2520-2000

Material: MR

Thickness:0.155mm

Width: 615mm

Temper: DR8

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: bright

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm Frequently Asked Questions:

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: Can tinplate packaging be used for automotive products?

- Yes, tinplate packaging can be used for automotive products. Tinplate is a durable and corrosion-resistant material, making it suitable for protecting automotive components such as spare parts, lubricants, and chemicals. Additionally, tinplate packaging can be customized to meet specific requirements, ensuring the safe transportation and storage of automotive products.

- Q: What are the main properties of tinplate?

- Tinplate is a type of steel coated with a thin layer of tin, providing it with several key properties. It is highly corrosion-resistant, making it suitable for packaging food and beverages. It also has excellent solderability, allowing for easy joining and sealing of tinplate cans. Additionally, tinplate has good formability, enabling it to be shaped into various container forms. Lastly, its aesthetic appeal and the ability to print on its surface make it an ideal choice for attractive packaging designs.

- Q: How does tinplate compare to paperboard in terms of packaging applications?

- Tinplate and paperboard have different characteristics that make them suitable for different packaging applications. Tinplate is known for its durability, resistance to moisture, and ability to provide a barrier against light, air, and odors. It is commonly used for packaging food and beverages, especially canned goods, as well as for aerosol cans and metal containers. Paperboard, on the other hand, is lightweight, flexible, and easily customizable. It is often used for packaging dry goods such as cereal boxes, pharmaceuticals, cosmetics, and certain types of food. Both materials have their strengths and weaknesses, and the choice between them depends on factors such as the specific product being packaged, desired shelf life, branding requirements, and environmental considerations.

- Q: How does tinplate contribute to the reduction of food waste?

- Tinplate contributes to the reduction of food waste by providing a highly protective and durable packaging material for various food products. Its corrosion-resistant properties and ability to maintain food freshness for extended periods help to prevent spoilage and extend shelf life. Additionally, tinplate's ability to be easily recycled promotes sustainable packaging practices, reducing environmental impact and further supporting efforts to minimize food waste.

- Q: What are the typical lead times for tinplate tooling?

- The typical lead times for tinplate tooling can vary depending on the complexity of the project and the specific requirements. However, on average, lead times for tinplate tooling can range from a few weeks to a couple of months.

- Q: What are the main uses of tinplate?

- The main uses of tinplate include packaging food and beverages, manufacturing cans for aerosol products, creating decorative tin containers, and producing electrical equipment enclosures.

- Q: Can tinplate be used for packaging luxury goods?

- Yes, tinplate can be used for packaging luxury goods. Tinplate is a versatile material that offers several advantages, such as durability, strength, and an attractive appearance. It can be customized with various finishes, including high-quality printing and embossing, making it suitable for luxury packaging needs. Additionally, tinplate provides excellent protection against moisture, light, and other external factors, ensuring the preservation and presentation of luxury goods.

- Q: Can tinplate be used for packaging chemicals?

- Yes, tinplate can be used for packaging chemicals. It is a commonly used material for packaging due to its durability, resistance to corrosion, and ability to protect against light and oxygen. Tinplate is also known for its ability to withstand various temperatures and pressures, making it suitable for storing and transporting a wide range of chemicals safely.

- Q: What are the differences in the corrosion behavior of two ferrous iron products?

- Tinplate is a tin covered with tin, it is not easy to rust, also known as tin iron. This kind of galvanized steel in a long time Chinese called "tin", some people think that the tin plate cans was made from the Guangdong province of Macao (English Macao readable if imported, tin) so called "tin".

- Q: What are the different methods of printing on tinplate?

- There are several methods of printing on tinplate, including lithography, screen printing, and digital printing. Lithography involves transferring an image onto a metal plate, which is then used to print onto the tinplate. Screen printing uses a mesh screen to apply ink onto the tinplate through open areas of the screen. Digital printing utilizes computer-controlled printers to directly apply ink onto the tinplate, allowing for greater flexibility and detailed designs.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords