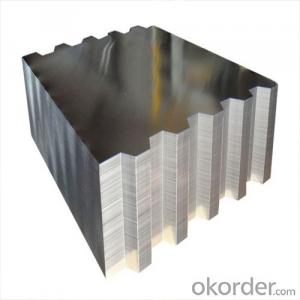

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.33mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrolytic Tinplate

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

Specification of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.33mm:

Standard: ISO 11949 -1995

Material: SPCC

Thickness:0.33mm

Width: 685mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: silver

Frequently Asked Questions:

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: What kind of material is tinplate?

- This past China lamp tin plate made of kerosene, shaped like a horse, so called "tin". The name "tinplate" is not exact. Therefore, in 1973, when the Chinese tin plate meeting was called "tinplate", the official document no longer used the name "tinplate".

- Q: How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts by being a highly recyclable material. It can be used repeatedly without losing its properties, reducing the need for new resource extraction. Additionally, tinplate is commonly used for food and beverage packaging, which helps preserve products and reduces food waste. Its durability and corrosion resistance also extend the lifespan of products, making it a sustainable choice for various industries.

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used for manufacturing solar panels and wind turbines due to its high durability, corrosion resistance, and electrical conductivity properties. Tinplate is also recyclable, making it an environmentally friendly choice for renewable energy projects.

- Q: What are the common sizes and shapes of tinplate containers?

- Common sizes and shapes of tinplate containers include round cans, rectangular cans, and square cans. These containers can come in various sizes ranging from small tins for spices or cosmetics to larger tins for food products or industrial purposes.

- Q: What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products vary depending on their purpose and industry. However, some commonly seen sizes include cans ranging from small containers for food and beverages (such as soda cans) to larger ones for bulk products (such as paint cans). Tinplate products also come in various shapes, including rectangular, cylindrical, and irregular forms, to cater to different packaging needs and maximize storage efficiency.

- Q: How is tinplate manufactured?

- Tinplate is manufactured through a process called electroplating, where a thin layer of tin is applied onto a base metal, usually steel. The steel is first cleaned and then immersed into an electrolyte solution containing tin ions. An electric current is then passed through the solution, causing tin ions to be attracted and deposited onto the steel surface, forming a layer of tin. This tin coating provides the steel with corrosion resistance and enhances its appearance, making it suitable for various applications such as food and beverage packaging.

- Q: How does tinplate contribute to the preservation of historical artifacts?

- Tinplate contributes to the preservation of historical artifacts by providing a protective barrier against environmental factors such as moisture, oxygen, and light. It helps prevent corrosion, rusting, and degradation of the artifacts, thus extending their lifespan and maintaining their historical value.

- Q: Is tinplate affected by moisture or humidity?

- Yes, tinplate is affected by moisture or humidity. Tinplate is a thin sheet of steel coated with a layer of tin, which provides corrosion resistance. However, prolonged exposure to moisture or high humidity can cause the tin layer to react with the steel, leading to corrosion and degradation of the tinplate's properties. It is important to store and handle tinplate in conditions that minimize exposure to moisture and humidity to maintain its integrity.

- Q: How does tinplate resist corrosion?

- Tinplate resists corrosion due to the protective barrier created by the tin coating on the surface. This tin layer acts as a barrier, preventing direct contact between the base metal and the corrosive elements in the environment, thus preserving the underlying material from degradation.

- Q: How does tinplate packaging contribute to product protection against oxidation?

- Tinplate packaging contributes to product protection against oxidation due to its inherent properties. Tin is a highly corrosion-resistant material that acts as a barrier against external factors such as moisture, air, and light, which are known to accelerate oxidation processes. The tin coating on the tinplate acts as a protective layer, preventing direct contact between the product and the surrounding environment, thus reducing the risk of oxidation. This helps to extend the shelf life of products, maintain their quality, and preserve their flavor and nutritional value.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.33mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords