Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm Description

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

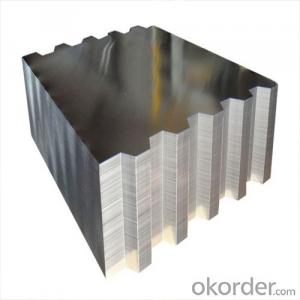

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm Specification

Standard: ISO 11949 -1995

Material: SPCC

Thickness:0.38mm

Width: 600mm -1150mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. It is a versatile material that offers durability, aesthetic appeal, and the ability to be customized with various designs and finishes. Tinplate packaging can enhance the perceived value of a product or gift, making it an excellent choice for promotional purposes.

- Q: What are the advantages of using tinplate for jewelry?

- One advantage of using tinplate for jewelry is its affordability. Tinplate is a cost-effective material compared to precious metals such as gold or silver, making it accessible to a wider range of consumers. Additionally, tinplate is lightweight, making it comfortable to wear for extended periods. It also offers versatility in design, allowing for intricate and detailed jewelry pieces. Lastly, tinplate is highly resistant to corrosion, ensuring the longevity and durability of the jewelry.

- Q: What are the main applications of tinplate in the photography industry?

- Tinplate is commonly used in the photography industry for producing photographic plates, which are used in traditional film cameras. These plates are coated with a light-sensitive emulsion and exposed to light to capture images. Additionally, tinplate is used for making tin cans to store and protect photographic film and other sensitive materials, ensuring their longevity and preservation.

- Q: What are the considerations for handling and storing tinplate coils?

- There are several considerations for handling and storing tinplate coils. Firstly, it is important to handle the coils with care to prevent any damage or deformation. This includes using appropriate lifting equipment, avoiding dropping or dragging the coils, and ensuring a smooth and controlled transfer process. Secondly, the storage environment should be suitable for tinplate coils. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion and rusting. It is recommended to keep the coils away from direct sunlight, extreme temperatures, and moisture. Additionally, proper stacking and organization of the coils is crucial. They should be stacked on flat and stable surfaces, with adequate support and spacing between each coil. Labeling the coils with relevant information such as date of manufacture, size, and grade can aid in efficient inventory management. Lastly, regular inspections should be conducted to identify any potential issues or defects. This includes checking for any signs of corrosion, dents, or scratches that may have occurred during handling or storage. Prompt action should be taken to address any problems to ensure the quality and integrity of the tinplate coils.

- Q: Can tinplate be shielded?

- Two kinds of materials of tinplate and paktong in general: tinplate is cheaper, weldability is good, but easy to rust, and relatively soft, compared to a large shield narrow cover will have problems. Alpaka relatively high prices, the weldability is poor, but can provide performance through tin, relativelyhard. At present, the use of shielding in the mobile phone, these two materials are more, but taking into account the cost or priority of tinplate

- Q: Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a commonly used material for food packaging due to its durability, corrosion resistance, and ability to protect against light and oxygen. It is also considered safe for food contact and can be easily sterilized, making it suitable for packaging sensitive products like baby food and formula.

- Q: How is tinplate used in the confectionery industry?

- Tinplate is commonly used in the confectionery industry for packaging purposes. It is used to make tin cans or containers that preserve and protect various confectionery products such as chocolates, candies, and biscuits. Tinplate offers excellent barrier properties against moisture, light, and oxygen, ensuring the quality and freshness of the confectionery items. Additionally, it provides a visually appealing and customizable packaging solution, making it popular in the confectionery industry.

- Q: Can tinplate be used for packaging cosmetics?

- Yes, tinplate can be used for packaging cosmetics. Tinplate is a popular choice for cosmetic packaging due to its durability, corrosion resistance, and ability to maintain product quality. It provides a protective barrier against external elements, ensuring the longevity of the product. Additionally, tinplate is easily printable, allowing for attractive and eye-catching designs on cosmetic packaging.

- Q: Can tinplate be used for energy storage applications?

- Yes, tinplate can be used for energy storage applications. Tinplate, which is a thin steel sheet coated with a layer of tin, offers good corrosion resistance and durability, making it suitable for various energy storage purposes. It can be used in the construction of batteries, capacitors, and other energy storage devices. Additionally, tinplate's ability to maintain airtightness and prevent moisture penetration makes it a reliable choice for storing and preserving energy.

- Q: What are the different surface finishes available for tinplate?

- The different surface finishes available for tinplate include bright, stone, and matt finishes.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.38mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords