Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Description

Electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

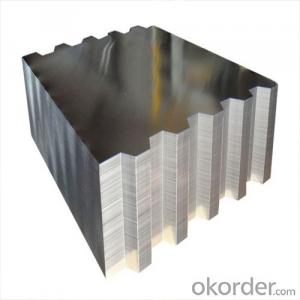

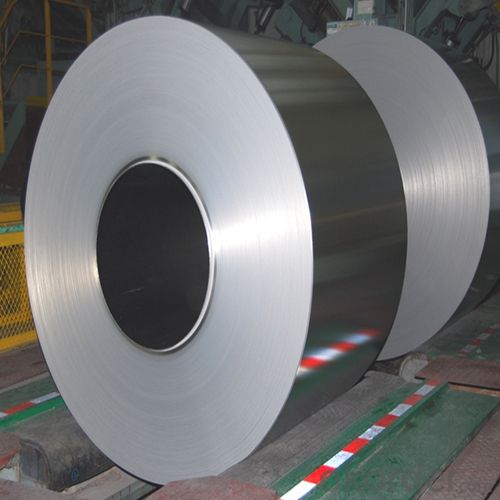

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Specification

Standard: GB/T2520-2000

Material: MR

Thickness:0.25mm

Width: 615mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: bright

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. Tinplate is a versatile material that is durable, visually appealing, and can be easily customized with various designs. It offers a premium look and feel, making it an excellent choice for creating attractive promotional or gift packaging that can leave a lasting impression on recipients.

- Q: What are some common tinplate products?

- Some common tinplate products include food cans, beverage cans, aerosol cans, metal closures, and tinplate packaging for various consumer goods.

- Q: What are the common uses of tinplate?

- Tinplate is commonly used for packaging food and beverages, such as cans for canned fruits, vegetables, and soups. It is also utilized in the manufacturing of aerosol cans, bottle caps, and metal closures. Additionally, tinplate finds applications in the production of electrical equipment, automotive parts, and various household items.

- Q: How can tinplate be customized for branding purposes?

- Tinplate can be customized for branding purposes through various methods such as printing company logos, brand colors, and product information directly onto the surface of the tinplate. Additionally, embossing or debossing techniques can be used to create raised or recessed brand elements for a more tactile experience. Furthermore, tinplate can also be customized through unique packaging designs or shapes that reflect the brand's identity and make it stand out on the shelves.

- Q: What is the difference between tinplate and tin-free steel?

- Tinplate is a thin steel sheet coated with a layer of tin, whereas tin-free steel is a steel sheet that does not have a tin coating. The main difference lies in their corrosion resistance properties, where tinplate offers better protection against rust due to the tin layer, while tin-free steel relies on other coatings or treatments to prevent corrosion.

- Q: What are the typical lead times for tinplate production?

- The typical lead times for tinplate production can vary depending on factors such as the quantity required, complexity of the design, and the manufacturer's production capacity. However, on average, lead times for tinplate production usually range from several weeks to a few months.

- Q: Can tinplate be used for packaging pharmaceutical products?

- Yes, tinplate can be used for packaging pharmaceutical products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent corrosion resistance and protection. It is commonly used in the packaging industry due to its durability, strength, and ability to maintain product integrity. Tinplate containers can effectively safeguard pharmaceutical products from external factors such as moisture, light, and oxygen, ensuring their quality and shelf life.

- Q: What are the different tinplate surface finishes?

- Some common tinplate surface finishes include bright finish, stone finish, and matte finish.

- Q: What are the different ways to customize tinplate packaging?

- There are several ways to customize tinplate packaging. These include printing the packaging with custom designs, adding embossing or debossing for texture, applying special finishes like glossy or matte coatings, incorporating special effects like metallic or holographic foils, and using different colors or patterns. Additionally, custom shapes and sizes can be created to suit specific product requirements.

- Q: Can tinplate be formed into different shapes and sizes?

- Yes, tinplate can be easily formed into various shapes and sizes due to its malleability and flexibility.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords