Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm

The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths upto 550 +/-50 N/mm2, whereas single reduced material has strength less than 450 N/mm2 &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength upto 690 N/mm2 to the produced material.

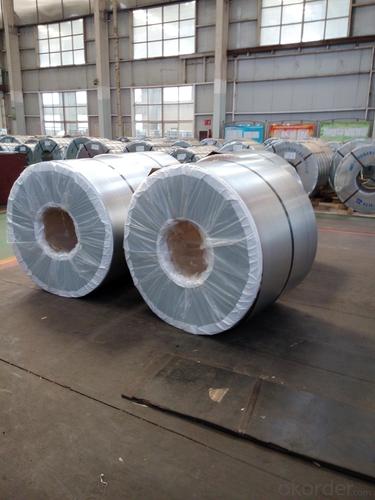

3.Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm Images

4.Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: What are the main regulations governing tinplate production?

- The main regulations governing tinplate production include health and safety standards, environmental regulations, quality control measures, and labeling requirements. These regulations ensure that tinplate production processes are conducted safely, with minimal impact on the environment, and that the final product meets quality standards. Additionally, labeling requirements ensure that tinplate products are accurately labeled and provide necessary information to consumers.

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. However, in general, properly stored tinplate canned goods can have a shelf life ranging from 1 to 5 years. It is important to check the expiration date and follow proper storage guidelines to ensure the quality and safety of the canned goods.

- Q: What's the difference between iron, aluminium, stainless steel, galvanized iron and tin?

- Iron is another kind of material. It is easy to be oxidized (embroidered) when it meets waterGalvanized sheet is made of iron, but zinc is plated on the surface to improve oxidation resistance. The price is cheap

- Q: How is tinplate coated for promotional items?

- Tinplate is typically coated for promotional items through a process known as electroplating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it, causing a layer of tin to deposit onto the surface. This coating not only enhances the appearance of the promotional items but also provides protection against corrosion and improves their durability.

- Q: What are the weight advantages of using tinplate?

- Tinplate offers several weight advantages compared to other packaging materials. Firstly, it is significantly lighter than materials like glass or aluminum, making it easier to handle and transport. This lightweight nature also contributes to lower shipping costs. Additionally, tinplate's lightness allows for more product to be packaged in a smaller space, maximizing efficiency and reducing storage requirements. Overall, the weight advantages of tinplate make it a preferred choice for many industries seeking cost-effective and efficient packaging solutions.

- Q: What are the different printing techniques used on tinplate?

- Some of the different printing techniques used on tinplate include lithography, offset printing, screen printing, and digital printing.

- Q: Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a type of steel coated with a thin layer of tin, making it corrosion-resistant and suitable for food packaging. Its durability and protective properties make it an ideal choice for maintaining the quality and safety of baby food and formula.

- Q: What are the main challenges in recycling tinplate?

- The main challenges in recycling tinplate include the separation of tin from the steel base, the removal of any contaminants or coatings on the tinplate, and ensuring the proper sorting and collection of tinplate waste to prevent it from ending up in landfills. Additionally, the energy-intensive process of melting and refining tinplate poses environmental concerns and requires adequate infrastructure for recycling facilities.

- Q: Raw material for zinc clad sheet? Can zinc clad plate replace tinplate?

- What is the meaning of zinc coated plate, is galvanized plate, galvanized sheet and tinplate is completely different, different materials, galvanized plate is carbon steel, tinplate is high-quality steel and tinplate is tin, zinc galvanized plate.

- Q: Can tinplate be used for industrial or automotive applications?

- Yes, tinplate can be used for industrial or automotive applications. Tinplate is a commonly used material in industries and automotive manufacturing due to its durability, corrosion resistance, and ability to withstand high temperatures. It is often utilized for making cans, containers, electrical components, automotive parts, and various other industrial applications.

Send your message to us

Electrolytic Tinplate for Useage of Chemical or Industrial Package 0.30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords