Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

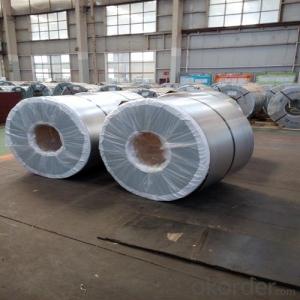

3.Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness Images

4.Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

5.FAQ of Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: Can tinplate be used for packaging electronic devices?

- Yes, tinplate can be used for packaging electronic devices. Tinplate is a common material used in the manufacturing of various packaging products, including cans, containers, and boxes. It provides durability, protection against moisture, and electromagnetic shielding, which makes it suitable for packaging electronic devices and safeguarding them during transportation and storage.

- Q: What are the regulations regarding tinplate packaging?

- The regulations regarding tinplate packaging vary depending on the country and the specific product being packaged. However, some common regulations include restrictions on the use of certain chemicals in the coating of tinplate, requirements for labeling and product information, and guidelines for food safety and hygiene. It is important for manufacturers and distributors to familiarize themselves with the specific regulations in their target market to ensure compliance.

- Q: What are the main factors affecting tinplate coil surface finish?

- The main factors affecting tinplate coil surface finish include the quality of the tin coating, the cleanliness of the substrate, the condition of the rolling mill, the temperature and pressure during the rolling process, the presence of impurities or contaminants, and the effectiveness of post-processing treatments such as annealing or tempering.

- Q: How is tinplate affected by exposure to oxygen?

- Tinplate is prone to oxidation when exposed to oxygen, leading to the formation of a tin oxide layer on its surface. This oxide layer can impact the appearance, adhesion, and corrosion resistance of the tinplate.

- Q: Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and makes it suitable for food contact applications. It is commonly used for making cans, containers, and other kitchen utensils due to its durability, easy cleaning, and ability to keep food fresh.

- Q: How does tinplate compare to plastic packaging?

- Tinplate packaging offers several advantages over plastic packaging. Firstly, tinplate is more durable and resistant to impacts, ensuring better protection for the product inside. It also provides better barrier properties, preventing oxygen and moisture from reaching the product and extending its shelf life. Additionally, tinplate is recyclable, making it a more sustainable choice compared to plastic, which is often difficult to recycle. Lastly, tinplate packaging has a premium look and feel, enhancing the overall visual appeal of the product on the shelves.

- Q: Can tinplate be used for pharmaceutical blister packaging?

- Yes, tinplate can be used for pharmaceutical blister packaging.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as the current market conditions, quality of the tinplate, and the quantity being purchased. It is recommended to check with suppliers or conduct market research for the most accurate and up-to-date pricing information.

- Q: How does tinplate perform in extreme temperatures?

- Tinplate performs well in extreme temperatures due to its high melting point and excellent heat resistance properties. It remains stable and maintains its mechanical strength even under extreme heat or cold conditions, making it a reliable material for various applications in extreme temperature environments.

- Q: What are the main factors influencing the pricing of tinplate?

- The main factors influencing the pricing of tinplate include the cost of raw materials, such as tin and steel, which can fluctuate due to supply and demand dynamics. Other factors include production and manufacturing costs, including energy and labor expenses, as well as market competition and global economic conditions. Additionally, trade policies, tariffs, and regulations can also impact tinplate pricing.

Send your message to us

Prime Quality Electrolytic Tinplate for Metal Containers Use 0.30mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords