Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm Description

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

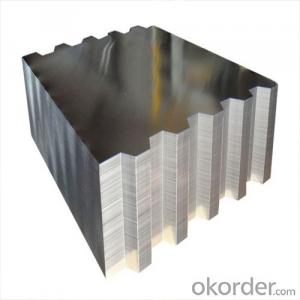

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm Specification

Standard: ISO 11949 -1995

Material: SPCC

Thickness:0.45mm

Width: 600mm -1150mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: How is tinplate tested for corrosion resistance?

- Tinplate is tested for corrosion resistance through various methods including salt spray tests, electrochemical impedance spectroscopy, and visual inspections to check for signs of rust or corrosion on the surface.

- Q: Can tinplate be used for toys and games?

- Yes, tinplate can be used for toys and games. It is a versatile material that is lightweight, durable, and easy to shape. Tinplate can be molded into various shapes and sizes, making it suitable for creating toy cars, action figures, board game components, and other playthings. Additionally, its glossy finish can enhance the aesthetic appeal of toys and games.

- Q: How does tinplate handle exposure to extreme temperatures?

- Tinplate generally handles exposure to extreme temperatures quite well. It has a high melting point and can withstand high temperatures without deforming or losing its structural integrity. Additionally, tinplate has good thermal conductivity, allowing it to dissipate heat quickly. However, prolonged exposure to extremely high temperatures may cause some oxidation or discoloration on the tin coating. Overall, tinplate is a reliable material for various applications in extreme temperature conditions.

- Q: What are the main growth drivers for the tinplate industry?

- The main growth drivers for the tinplate industry include increasing demand for sustainable packaging solutions, growth in the food and beverage industry, rising urbanization and disposable income, and technological advancements in manufacturing processes.

- Q: How does tinplate packaging contribute to product ease of use?

- Tinplate packaging contributes to product ease of use by providing durability and strength that ensures the product remains intact during transportation and handling. Its protective properties prevent damage, leakage, and contamination, ensuring the product inside remains fresh and safe for consumption. Additionally, tinplate packaging often includes convenient features such as easy-to-open lids, resealable options, and ergonomic designs that enhance the overall user experience and make the product more convenient to use.

- Q: Can tinplate be used for packaging products with sensitive electronic components?

- No, tinplate cannot be used for packaging products with sensitive electronic components as it can cause electromagnetic interference and potentially damage the components.

- Q: How does tinplate perform in terms of electrical conductivity?

- Tinplate has relatively low electrical conductivity compared to other metals, making it less suitable for applications that require high conductivity such as electrical wiring.

- Q: How is tinplate corrosion resistant?

- Tinplate is corrosion resistant due to the thin layer of tin that is applied to its surface. Tin acts as a protective barrier, preventing the underlying iron or steel from coming into contact with moisture or oxygen, which are the main causes of corrosion.

- Q: What are the common printing methods used on tinplate?

- The common printing methods used on tinplate include lithography, screen printing, and digital printing.

- Q: What are the benefits of using tinplate for roofing?

- Tinplate offers several advantages for roofing, including its durability, resistance to corrosion, ease of installation, and aesthetic appeal. It is a long-lasting material that can withstand harsh weather conditions and is less prone to damage from elements like hail or wind. Additionally, tinplate is highly resistant to rust and can maintain its structural integrity over time. Its lightweight nature makes it easier to handle and install, reducing labor and transportation costs. Lastly, tinplate roofing can enhance the overall appearance of a building, as it can be painted or coated to match various architectural styles.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.45mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords