Egrid App Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforcement in Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

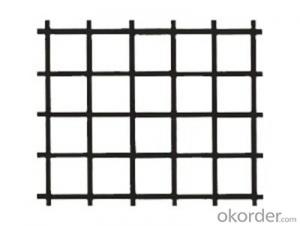

1. Specifications for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

Tensile Strength: 30KN*30KN-300KN*200KN

Mesh Size: 25.4*25.4mm

Width: 1-6m

Length: 50-300m

Elongation<4%

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

2. Technical Data for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

Specification | TGS-B-30-30 | TGS-B-50-50 | TGS-B-80-80 | TGS-B-100-100 | |

tensile strength (KN/m) | warp | 30 | 50 | 80 | 100 |

weft | 30 | 50 | 80 | 100 | |

Breaking elongation % | 3 max. | 3 max. | 3 max. | 3 max. | |

Aperture (mm) | 25*25 | 25*25 | 25*25 | 25*25 | |

Roll length (m) | 100 | 100 | 50 | 50 | |

rolls width (m) | 5.9 | 5.9 | 5.9 | 5.9 | |

3. Application for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

a. Used on asphalt pavement, bituminous cocrete pavement and cement pavement to prevent cracks from occurring and to prolon pavement service life.

b. Used as a basal reinforcement material for hillsides, reservoirs, harbours, ports, water channels and dams, seawalls, and similar site work.

c. Used to reinforce railroad subgrade on soft soil.

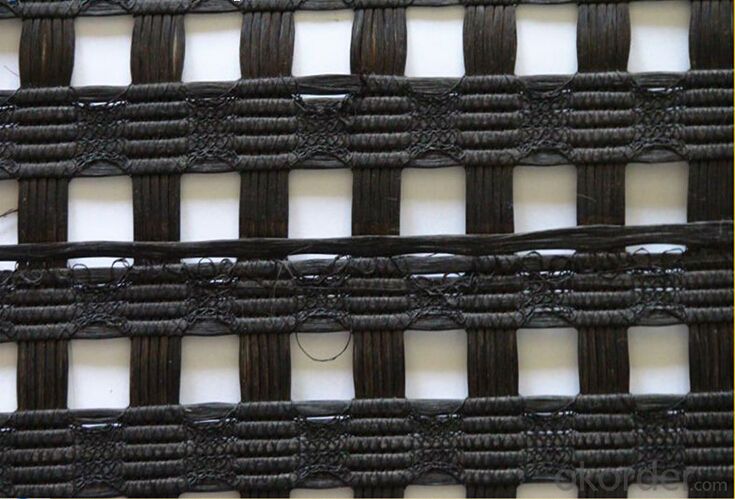

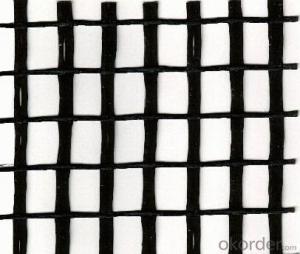

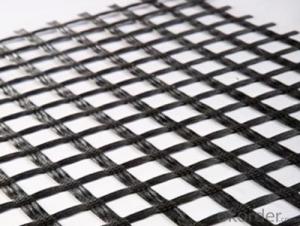

4. Photos for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

FAQ:

1.What's your payment terms?

T/T , LC at right

2. What's your pacakge?

one roll with two woven bags

3. Can you provide free samples?

yes, but our express fees are usually on buyer's account

- Q: Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. Geogrids are commonly used to reinforce and stabilize earth structures such as slopes and retaining walls. In environmental containment systems, geogrids can be utilized to enhance the stability and strength of liners and barriers, preventing soil erosion and providing long-term durability. They can also improve the overall performance of containment systems by increasing their load-bearing capacity and reducing the potential for geotechnical failures.

- Q: Can geogrids be used in soil reinforcement for oil and gas pipeline projects?

- Yes, geogrids can be used in soil reinforcement for oil and gas pipeline projects. Geogrids are commonly used to improve the stability and load-bearing capacity of soil, making them suitable for reinforcing the soil around pipelines. They help to prevent soil erosion, increase the overall strength of the soil, and provide support to the pipelines, ensuring their safe operation.

- Q: Can geogrids be used in mining operations?

- Yes, geogrids can be used in mining operations. Geogrids are commonly used in mining to reinforce soil and rock structures, provide stability to slopes and walls, and prevent erosion. They can also be used to improve the load-bearing capacity of roads and foundations, which is essential in mining operations.

- Q: Are geogrids suitable for reinforcement of railway ballasts?

- Yes, geogrids are suitable for reinforcement of railway ballasts. Geogrids provide excellent stabilization and reinforcement properties, reducing the lateral movement of ballast particles and increasing the overall stability of the railway tracks. They effectively distribute the load and enhance the strength of the ballast, resulting in improved track performance, reduced maintenance needs, and increased lifespan of the railway infrastructure.

- Q: Can geogrids be used in subgrade stabilization applications?

- Yes, geogrids can be used in subgrade stabilization applications. Geogrids are commonly used to reinforce and stabilize the soil in subgrade areas, improving its load-bearing capacity and reducing settlement. They are effective in stabilizing weak or soft soils, preventing lateral spreading, and enhancing the overall stability and performance of the subgrade.

- Q: Are geogrids suitable for reinforcement of airport runways?

- Yes, geogrids are suitable for the reinforcement of airport runways. Geogrids are high-strength materials that can effectively distribute loads and provide stability to the runway surface. They have been extensively used in civil engineering projects, including airport runway construction, to enhance the strength and durability of the pavement structure. Geogrids help to minimize rutting, cracking, and other forms of distress, improving the overall performance and longevity of airport runways.

- Q: Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used in retaining wall construction to improve stability and strength. They are placed within the soil layers of the wall to provide additional support, prevent soil movement, and increase the overall load-bearing capacity of the structure.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and preventing soil erosion. They are installed within the soil or rock layers to distribute the tensile forces and improve the overall strength of the cutting. This helps to reduce the risk of slope failure and maintain the stability of the railway embankment, ensuring safe and efficient train operations.

- Q: What is the difference between plastic geogrid and grid

- Geogrid is suitable for various kinds of dams and subgrade reinforcement, slope and tunnel wall reinforcement. Large airport, parking lot, wharf freight yard and other permanent bearing foundation reinforcement.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Egrid App Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforcement in Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords