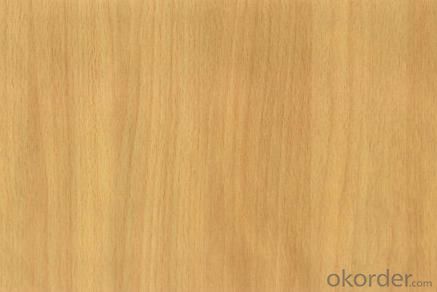

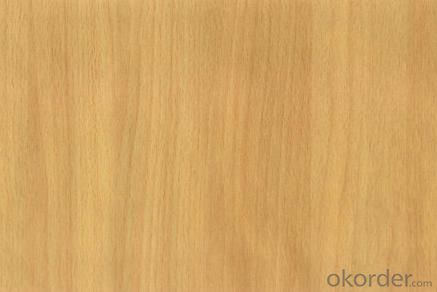

Egger Melamine Faced Sliced Cutting Beech Veneered MDF Panels

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Sliced Cutting Sapele veneered MDF are usually be used in decoration and furniture.

Characters:

Light, easy to install, disassemble and beautiful.

Products Details:

Detailed Specification:

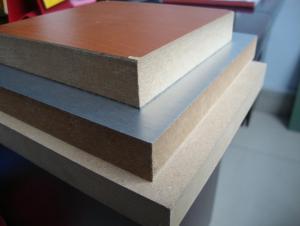

Product name:Sliced Cutting Beech veneered MDF

Size: 1220*2440mm

Thickness: 4mm-18mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

2. Packing Details of Sliced Cutting Beech veneered MDF

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

FAQ:

Q1. How long can we receive the product after purchase?

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce

- Q: Melamine plywood and fire board panels which is good? That environmental protection?

- As for what you say environmental protection, in fact, both have melamine ingredients, but the fire board compared to deal with better, it is recommended to use fire board

- Q: What is called a panel?

- Plywood, is used in the decorative trim plywood, and some plywood to paint finishing, and some are paint-free, the specifications are long 2440MM wide 1220MM.

- Q: What is the double-panel, wardrobe with this back to do it?

- Double-sided can not look at the main material environmental protection is not

- Q: Plywood hot press and plywood hot press is different

- Different types of plywood have different requirements on the performance of the press: ordinary plywood, aviation plywood, plastic plywood, wood laminated plastic plate, ship plywood manufacturing requirements of the pressure in turn increased.

- Q: Will the fire board be used as a plywood for furniture?

- Yes, the fire board veneer furniture has a lot of years ago, fire board wear, fire, rich colors, decorative effect is good.

- Q: The good and the bad of wood is not determined by the severity

- 4, smell: with the nostril paste into the material smell, if the blockboard fragrance smell, indicating formaldehyde content is low, if the smell of pungent is a higher formaldehyde content.

- Q: What is the thickness of the trim panel?

- Decorative panel specifications commonly used 2440mm * 1220mm, 1000mm * 2000mm, 1220mm * 2000mm, 1200mm * 3000mm.

- Q: What are the shortcomings and advantages of oak plywood?

- Oak furniture Disadvantages 2: oak furniture is relatively easy and rubber wood furniture confused, will affect the consumer's judgment. In the domestic oak furniture, although all aspects of the process are very good, but the general oak furniture is not a good maintenance, then after a year or so may be the old contraction.

- Q: What are the types of wood panel?

- 5. Ash: yellow and white, delicate structure, texture straight and thick, shrinkage rate is small, wear and impact resistance is good.

- Q: The difference between eco-board and blockboard

- The carpentry mainly refers to the blockboard commonly known as the big core board, which is made of two pieces of veneer center. Central board is made by the wood side by drying the future, processed into a certain standard of wood, made by the puzzle machine stitching.

Send your message to us

Egger Melamine Faced Sliced Cutting Beech Veneered MDF Panels

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords