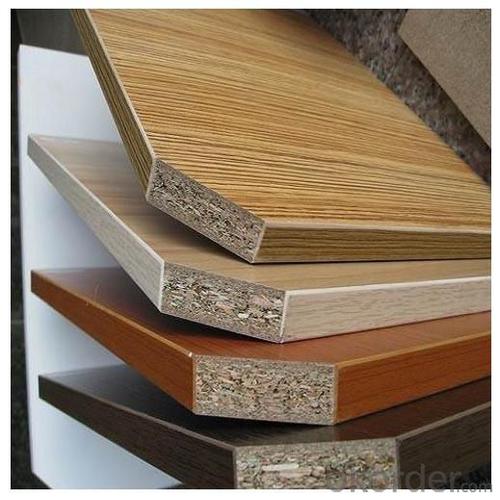

Melamine Faced Chipboard/Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Melamine Faced Chipboard/Particle Board

---Size :1220x2440mm,1830x2440mm,1830x3660mm

---Thickness :2.5-30mm

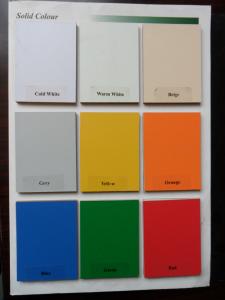

---Cule:MR/E1 /E2 /Melamine/WBP

---Face/Back: Sanding or unsanding, plain/veneer/ melamine paper

---Usage:Kitchen, furniture, cabinet

---Material: Poplar/combi

---Certificate: ISO 9001,ISO14001,CARB,CE

---Main Market: Middle-east, America, Canada, European, India,etc.

Features of Melamine Faced Chipboard/Particle Board

1) High bending strength

2) little linear expansion con-efficient

3) Strong nail holding

4) Moisture proof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

Producs Show

Packing and Loading for Melamine Faced Chipboard/Particle Board

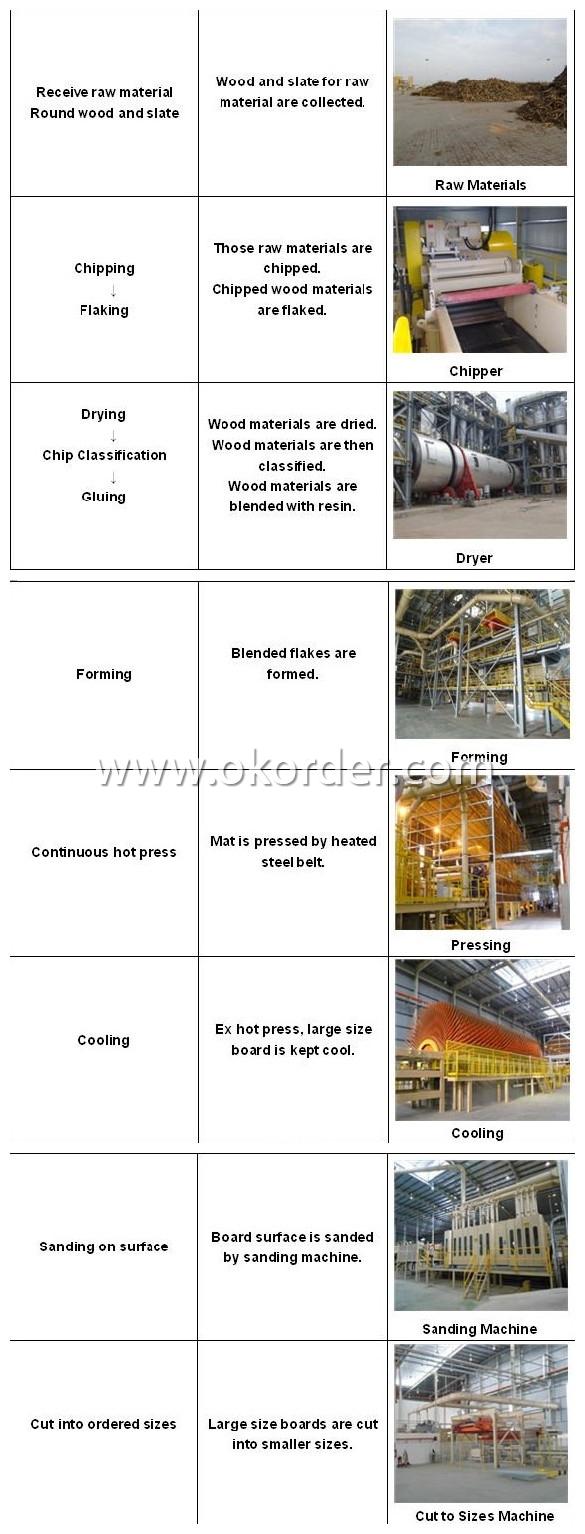

Production Progress of Melaine Faced Chipboard/ Particle Board

- Q: Melamine plywood and fire board panels which is good? That environmental protection?

- As for what you say environmental protection, in fact, both have melamine ingredients, but the fire board compared to deal with better, it is recommended to use fire board

- Q: What are the identification methods for the panel?

- The so-called adapter board: the use of some of the tailings, or off the assembly line and the different length of the floor through a number of fingerprints to engage in splicing or as a pure solid wood flooring to deceive consumers. Identification methods: often can be through the surface of the grain to carry out some identification, often the floor of the wood is relatively natural to the comparison, basically that there is no color.

- Q: The good and the bad of wood is not determined by the severity

- 1, see: the quality of the board should be smooth and smooth, no defects, from the side to see whether the thickness of the core plate, blockboard and multilayer will have to observe whether the phenomenon of overlapping core. The panel is made of rice (usually white). You can keep the long-term smoothness of the panel. Generally a stack of plywood texture is no difference between the artificial veneer veneer, dyed veneer, just in the selection, dipped in water, gently rub off, fade that is dyed; natural veneer plywood nice,

- Q: What is the difference between a melamine plywood and a flat sheet?

- Coated flat paste board refers to the quality of man-made board covered with a layer of coated paper, coated paper and wood-based panels by thermal pressure and the formation of building cover plate;

- Q: Do the closet and the door, joinery outside the paste Boeing soft leather and veneer in the performance, quality, visual What is the difference?

- Use the place is not the same, if the decoration inside the paste also, very little so dry. If the hard to compare these two, of course, of course decorated panels, from the performance, quality, vision, cost are better than the Boeing film and expensive.

- Q: What are the advantages and disadvantages of decorative panels?

- Melamine veneer makes the appearance of furniture strong, printed with color or imitation wood grain of paper itself is fragile, melamine plate in the transparent resin soaked in the formation of the film after the film to be hard, this film and the substrate hot pressing Into a body has a very good performance, with it to fight the furniture do not have to paint, the surface of the natural formation of protective film, wear, scratch resistance, Naisuan Jian, resistant to heat, pollution.

- Q: How to identify the furniture board is good or bad

- Method 2: see if there is no place to plywood, you can look at the wood, and now the market is mostly selling the MDF, particleboard, solid wood three categories. Density board points high density, medium density, resolution method, look inside the delicate degree of wood fiber (no miscellaneous wood slag).

- Q: Do the furniture of the woodworking board need to be plywood?

- Of course, to paste the panel, and then according to preferences brush varnish or paint

- Q: How many types of wooden lines

- First, the decorative effect, that is, with good processing lines to cover the poor visual effects of the site;

- Q: What is the particleboard veneer

- Mainly used in furniture and construction industry and trains, car manufacturing.

Send your message to us

Melamine Faced Chipboard/Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords