18mm Satin Surface Finish Melamine Faced MDF Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Melamine MDF Board are used for furniture making and house decoration

Characters:

Light, easy to install and disassemble and beautiful.

Products Details:

Detailed Specification:

Product name: Satin Surface Finished Melamine MDF Board

Size: 1220*2440mm

Thickness: 3mm-18mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

2. Packing Details of Melamine Faced MDF Boards

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

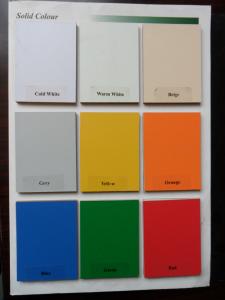

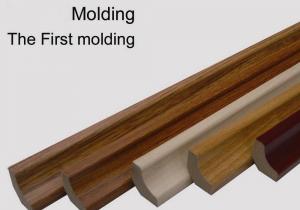

3. Surface Texture of Melamine Faced MDF Boards

Satin, Pearl, Wood Grain, Corrugation.

FAQ:

Q1. How long can we receive the product after purchase?

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce.

- Q: What are the top ten brands of 2015?

- The Company's shares were traded on the Shenzhen Stock Exchange on May 10, 2005.

- Q: Plywood hot press and plywood hot press is different

- Plywood hot press according to the operating mode sub-cycle and continuous two kinds of domestic commonly used is a multi-layer multi-cycle hot press. It consists of three parts: hot press body, control drive part (hydraulic system and electronic control system), heating system.

- Q: What are the quality requirements for decorative panels?

- Decorative panels - the construction quality requirements: First, first of all depends on the floor of the panel is flat, solid Second, depends on the panel texture direction or pattern is not one to third, look at the face of the panel is empty , Look around the panel is not sticky

- Q: Bamboo stickers, polymer panels which is good?

- Do you say that the veneer is not the surface with a decorative plate, which we call the panel? Decorative panels are generally: melamine decorative panels, veneer decorative panels, paint decorative panels (Polaroid board), stickers and other decorative panels. Which use the largest amount of melamine decorative panels, veneer decorative panels the most high-end. As for the glue, the general use of more than white plastic.

- Q: What kind of glue when you use it?

- White latex (environmental protection is better, and the price is relatively cheap)

- Q: Wall shape plywood with light bulb how much appropriate

- 10cm is enough on the one hand you have to look good to see too little slightly stingy too much easy to see inside the lamp

- Q: Double-sided eco-board with what adhesive stickers

- Double veneer eco-board is not made of adhesive, but hot-pressed melamine impregnated paper, the paper itself is plastic.

- Q: Where to do plate, plywood, melamine ecological board, furniture board, can be, it is best to professional point.

- Second, if you want to use these plates to make furniture, as long as you want to do what furniture, in this market which have their customers can achieve for you. Near the manufacturers can be achieved

- Q: What is the difference between solid wood veneer doors and solid wood composite doors?

- Paint inside the door as long as the brand inside the door are solid wood, the price is more expensive, the outside pressure is the high density board less than 6 mm, the density board is better, on the outside of the tree is the skin of the general door are 3 thick, brand doors are at least six thick, the difference lies in the material, and processing technology, technology is not reached, then also white pull

- Q: What is the particleboard veneer

- Particleboard veneer is the particle board to do the substrate, in its surface paste a variety of veneer materials, such as melamine impregnated paper, melamine plywood, veneer veneer and so on.

Send your message to us

18mm Satin Surface Finish Melamine Faced MDF Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords