Eco Packaging Tape NZ - Custom Printing OPP Packing Tape High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: BOPP film

Adhesive Side: Single Sided

Adhesive: Water Based Acrylic

Use: Carton Sealing and Packing,Light Duty Packing,Bounding,Holding and other office and household use

Design Printing: Offer Printing

Place of Origin: China (Mainland)

Model Number: High Quality Colorful Printing Opp Adhesive Packing Tapes

Color: Clear, Tan, Yellowish, Brown, Yellow, White, Black, Blue, Green, Red etc.

Standard Size: 48mm x 66m, 50mm x 50m, 1.28m x 4000m, etc

Product Discription

Applications

Economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Advantages:

OPP tape, superb tack and adhesion to surface

Strong grip that is ensured because of an excellent adhesive backing

Quality processing equipment that guarantees consistent quality

Peak performance even under extereme conditions of pressure and temperature

Sticks on all types of surfaces (paper, plastic, wood, glass, fiber and metal)

Consistent quality

On time delivery

Effective and timely communication

- Q: What are the benefits of using UV-resistant packaging tape?

- There are several benefits of using UV-resistant packaging tape. First and foremost, UV-resistant packaging tape is designed to withstand prolonged exposure to sunlight and prevents the tape from deteriorating or degrading over time. This is especially important when shipping or storing items outdoors or in areas with direct sunlight. UV-resistant tape can maintain its adhesive properties and structural integrity for longer periods, ensuring that packages remain securely sealed. Additionally, UV-resistant packaging tape helps protect the contents of packages from damage caused by UV rays. Sunlight can cause fading, discoloration, or degradation of certain materials, such as paper, fabrics, or plastics. By using UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Another advantage of UV-resistant packaging tape is its long-lasting adhesion. Unlike regular packaging tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specifically formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages coming open or items getting damaged during transit. Moreover, UV-resistant packaging tape provides added peace of mind for both the sender and the recipient. By using tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, maintaining the professional image and customer satisfaction. This is particularly crucial when shipping valuable or delicate items that require extra protection. In conclusion, the benefits of using UV-resistant packaging tape include enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By choosing UV-resistant tape, individuals and businesses can safeguard their packages and the contents within, even when exposed to prolonged sunlight.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape generally does not perform well on oily or greasy surfaces. The adhesive on packaging tape is designed to bond to clean and dry surfaces, so when applied to oily or greasy surfaces, the tape may struggle to stick securely. The oil or grease can act as a barrier, preventing the adhesive from effectively bonding to the surface. As a result, there is a higher probability of the tape peeling or coming loose. To ensure proper adhesion on oily or greasy surfaces, it is recommended to thoroughly clean and degrease the surface before applying packaging tape. Using a degreasing agent or detergent can help remove the oil or grease, allowing the tape to adhere more effectively. Additionally, selecting a high-quality packaging tape with a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Yes, packaging tape does come in different dispenser options for ease of use. There are various types of dispensers available in the market that are specifically designed to make the task of sealing boxes or packages easier and more convenient. These dispensers come in different sizes, styles, and functionalities to cater to different needs and preferences. One common type of dispenser is the handheld dispenser, which is lightweight and compact, making it easy to handle and maneuver. These dispensers often have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, there are also tabletop or benchtop dispensers available. These dispensers are designed to sit on a surface and hold the tape roll securely in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Furthermore, there are automatic or electric dispensers that take convenience to the next level. These dispensers can automatically dispense and cut the tape with the push of a button, reducing the effort and time required for packaging tasks. They are particularly useful for high-volume or repetitive packaging needs. In summary, packaging tape does come in different dispenser options to suit various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options available that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Sealing packages containing delicate fabrics or clothing with packaging tape is possible. However, it is crucial to exercise caution and implement specific precautions to ensure the protection of these fragile items. Here are some tips to guarantee safe packaging: 1. Opt for a broad, transparent packaging tape: Select a tape that provides a larger adhesion surface area due to its width. Transparent tape is preferable as it reduces the risk of leaving visible residue or marks on the fabric. 2. Apply a double layer of tape: Enhance the strength and security of the package by using two layers of packaging tape. This will help prevent accidental peeling during transit. 3. Securely wrap the delicate items: Before sealing the package, make sure to wrap the delicate fabrics or clothing in a protective layer such as tissue paper or bubble wrap. This additional layer will act as a buffer, safeguarding the items from potential damage caused by the tape. 4. Avoid excessive tension: Exercise caution while sealing the package and avoid pulling the tape too tightly. Excessive tension may stretch or distort the fabric, potentially damaging the delicate item. 5. Explore alternative options: For particularly fragile or valuable delicate items, it may be beneficial to consider alternative packaging materials such as acid-free tissue paper or garment bags. These options offer additional protection and are specifically designed for preserving delicate fabrics and clothing. Ultimately, while packaging tape can be utilized for sealing packages containing delicate fabrics or clothing, it is essential to handle the items with care and implement appropriate measures to minimize the potential for damage during the packaging process.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various surfaces, including those that are not completely flat or smooth. Its adhesive properties make it effective in securing packages with irregular surfaces, ensuring they remain sealed during transit or storage.

- Q: What are the benefits of using tear-resistant packaging tape?

- Using tear-resistant packaging tape comes with various advantages. To begin with, the use of tear-resistant packaging tape provides added security and protection for your packages during transit or storage. The tape's strong adhesive and tear-resistant material guarantee its integrity, preventing any tampering or accidental tearing of the packaging. This helps to maintain the contents' integrity and minimizes the risk of damage or loss. Furthermore, tear-resistant packaging tape offers greater durability and longevity compared to regular packaging tapes. Its sturdy design and resistance to tearing make it perfect for packaging heavy items, those with sharp edges, or those susceptible to rough handling. This ensures that the tape remains intact throughout the entire shipping process, reducing the need for re-taping or potential damage to the package. In addition, tear-resistant packaging tape often possesses weather-resistant properties, enabling it to withstand various environmental conditions. It is designed to resist moisture, extreme temperatures, and UV exposure, making it suitable for long-distance shipping or storage in different climates. This prevents the tape from deteriorating or weakening, ensuring that your packages remain securely sealed and protected. Moreover, tear-resistant packaging tape is user-friendly and provides a professional finishing touch to your packages. Its strong adhesive allows for quick and secure bonding to different surfaces such as cardboard, plastic, or metal. This ensures that the tape stays in place and does not unravel or loosen during transit. Additionally, tear-resistant packaging tape is available in a range of sizes and colors, allowing you to personalize your packaging and create an aesthetically pleasing presentation for your customers. To summarize, the advantages of using tear-resistant packaging tape include enhanced security, increased durability, weather resistance, ease of use, and a professional appearance. By investing in tear-resistant packaging tape, you can ensure that your packages are well-protected, reduce the risk of damage or tampering, and enhance the overall shipping experience for both you and your customers.

- Q: How long does packaging tape last?

- The durability of packaging tape is heavily influenced by different factors including the tape's quality, the conditions it encounters, and its storage method. In general, packaging tape has the potential to endure for several months to a few years. Nevertheless, it is crucial to acknowledge that as time goes on, the adhesive qualities of the tape might start to diminish, resulting in a loss of its adhesive strength. Additionally, exposure to extreme temperatures, moisture, and sunlight can expedite the tape's decay. Hence, it is advisable to employ packaging tape within its recommended shelf life and keep it in a cool and dry area to guarantee its efficacy when required.

- Q: What is the profit margin of the transparent tape for packaging?

- Factory profits higher, up to 20%, but the pressure is more severe, dealers only 3%-7%, payment is generally cash.

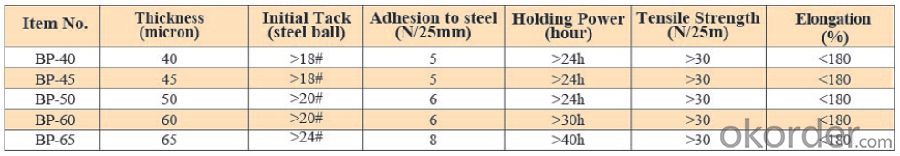

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

Send your message to us

Eco Packaging Tape NZ - Custom Printing OPP Packing Tape High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords