Amazon Scotch Packaging Tape - Double Sided Tissue Tape Water Based Acrylic Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

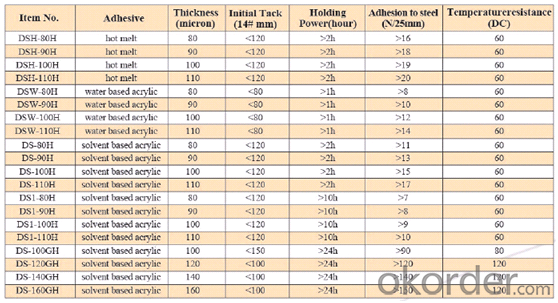

Typical Physical Reports of Double Sided Tissue Tape

Packaging Detail

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Indeed, plastic lunch boxes can be sealed using packaging tape. This type of tape is crafted to possess formidable strength and adhesive capabilities, rendering it appropriate for sealing a wide array of materials, plastic included. Its capacity to provide a secure seal ensures that the contents of the lunch box remain fresh and safeguarded. Nevertheless, it is crucial to acknowledge that using packaging tape on plastic lunch boxes may result in residue or surface damage upon removal. To avoid such complications, it is advisable to employ tape specifically engineered for sealing food containers or explore alternative methods such as rubber bands or clips, which are designed to secure plastic lunch boxes without causing any harm.

- Q: Can packaging tape be recycled?

- Packaging tape can indeed be recycled, but its recyclability depends on the type of tape and the recycling facilities in your area. The commonly used clear or brown polypropylene tape, for example, cannot be recycled along with regular paper or plastic waste. However, certain recycling centers do accept specific types of tapes for recycling, such as those made from paper or with water-based adhesives. It's crucial to contact your local recycling center to determine their policy on packaging tape recycling and any specific requirements they may have. Furthermore, taking the tape off cardboard boxes before recycling them can enhance the recycling process. If recycling is not feasible, it is recommended to either reuse the packaging tape or dispose of it properly in the regular trash.

- Q: What are the considerations for using packaging tape on painted surfaces?

- When considering using packaging tape on painted surfaces, there are several important considerations to keep in mind. Firstly, it is crucial to assess the type and condition of the paint on the surface. If the paint is old, flaking, or in poor condition, using packaging tape may cause further damage such as peeling or chipping off the paint. In such cases, it is advisable to avoid using tape directly on the painted surface. Another important consideration is the adhesive strength of the packaging tape. Some tapes have strong adhesives that may stick firmly to the painted surface, making it difficult to remove without damaging the paint. It is recommended to test a small, inconspicuous area with the tape to ensure it can be safely removed without leaving residue or causing any harm. Furthermore, it is crucial to consider the duration for which the tape will be applied. If the tape is intended to be left on the painted surface for an extended period, there is a higher risk of it causing damage. Over time, the adhesive may bond more strongly with the paint, making it harder to remove without causing any harm. Additionally, the surface texture plays a role in determining the suitability of using packaging tape. Rough or uneven surfaces may not allow the tape to adhere properly, leading to lifting or peeling, which can damage the paint. Lastly, it is essential to consider the purpose of using packaging tape on the painted surface. If the objective is to protect the paint from scratches or damage during transportation or storage, alternative methods such as using protective sheets or bubble wrap may be more suitable and less likely to harm the paint. In conclusion, when considering using packaging tape on painted surfaces, one must assess the type and condition of the paint, adhesive strength, duration of application, surface texture, and the purpose of using the tape. By taking these considerations into account, one can ensure that the tape is used safely without causing any damage to the painted surface.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. It provides a strong and reliable adhesive that helps keep the bags securely sealed.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Yes, packaging tape can be used for sealing packages containing medical or pharmaceutical products. However, it is important to ensure that the packaging tape used is of high quality and specifically designed for such sensitive products to maintain their integrity and prevent any contamination.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, it is important to consider the adhesion and durability of the tape. The texture of the surface can affect how well the tape sticks and stays in place. It is advisable to choose a tape with strong adhesive properties that can effectively bond with the texture of the surface. Additionally, the tape should be able to withstand any movement or stress that may occur due to the textured surface. It is also crucial to ensure that the tape does not damage or leave residue on the textured surface when it is removed.

- Q: How does packaging tape perform in high-temperature conditions?

- Packaging tape generally performs well in high-temperature conditions, but its effectiveness may vary depending on the specific type and quality of the tape. Most packaging tapes are designed to withstand a range of temperatures and are typically heat-resistant up to a certain degree. However, it is important to note that extreme temperatures, particularly those exceeding the tape's specified heat resistance limit, can affect its adhesive properties and overall performance. In high-temperature conditions, the adhesive on packaging tape may soften or weaken, leading to reduced bonding strength and potential tape failure. This can result in packages opening or becoming less secure during transit or storage. Furthermore, heat can cause the tape to become less flexible, making it more prone to cracking or breaking. Hence, it is crucial to select packaging tape that is specifically designed for high-temperature environments if you anticipate exposure to extreme heat. Certain types of packaging tape, such as fiberglass-reinforced or high-temperature resistant tapes, are better suited for withstanding high temperatures. These tapes are often made with special adhesives and materials that offer enhanced heat resistance and improved performance in extreme conditions. They are designed to maintain their adhesive strength, bonding capability, and structural integrity even when exposed to elevated temperatures. In summary, while packaging tape can generally withstand high-temperature conditions, its performance may be compromised if subjected to extreme heat. Using tapes specifically designed for high-temperature environments can help ensure optimal performance and securely seal packages even in challenging conditions.

- Q: Can packaging tape be used for sealing furniture or home goods?

- Yes, packaging tape can be used for sealing furniture or home goods. Packaging tape is designed to provide a secure and strong seal, making it suitable for various purposes including sealing boxes and packages. When used on furniture or home goods, packaging tape can help keep the item protected during transportation or storage. It is important to ensure that the tape is applied properly and that it does not damage the surface or leave any residue. Additionally, depending on the weight and size of the item, it might be more appropriate to use specialized tapes or techniques for sealing furniture or home goods to ensure maximum protection.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

- Q: Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. Packaging tape is designed to adhere to various surfaces, including plastic, and provides a secure seal to prevent the contents of the container from spilling or getting damaged. It is commonly used for sealing boxes during shipping or storage, but it can also be used effectively on plastic containers. However, it is important to ensure that the tape is firmly applied and that all edges and seams are properly sealed to maintain the integrity of the container.

Send your message to us

Amazon Scotch Packaging Tape - Double Sided Tissue Tape Water Based Acrylic Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords