EASY-CLEANING PREPAINTED STEEL COIL FOR COLD ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With Aluzinc as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

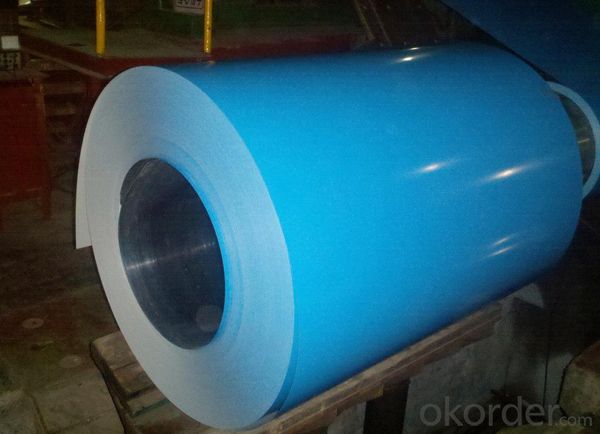

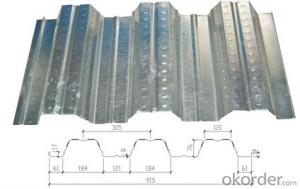

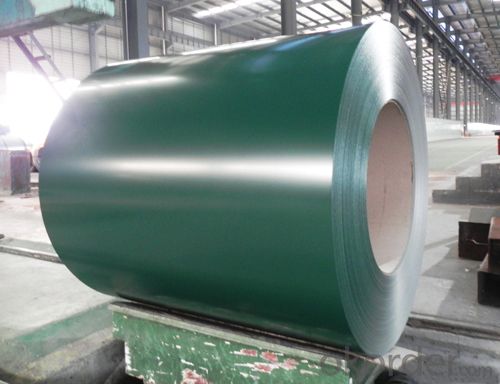

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.Where is your company quality standard?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Middle and High Quality.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Glasses and plastic glasses how to distinguish

- 1, strictly speaking, their raw materials are basically the same, but the difference lies in the production process is different. Plastic glasses production process for injection molding, the first production mold, and then melt the plastic into the mold to form glasses frames. Is the first plastic through the compression process to form a sheet, and then through the NC machine tool cutting the formation of glasses frame, the density is higher than the plastic glasses, so the heavier weight, and more durable, easy to wear after deformation; 2, plastic glasses, the material is relatively low, and now very few people have worn, and the pattern is also called boring, not suitable for the pursuit of fashion young people choose.As the plate is the first form of glasses, so you can produce all kinds of Pattern, beautiful fashion, is the best choice for many young people. Table glasses and plastic glasses the difference between the glasses glasses not only light and will not cause skin sensitivity, the use of materials is environmentally friendly products, our skin more no side effects, Relatively wear, the disadvantage is not easy to heat processing adjustment.

- Q: What is the difference between steel sheet and coil?

- The plate is the rationale for the price of the coil

- Q: What is the board Fang material

- 1, board Fang material refers to the selection of easy texture, performance, heat, anti-burning, waterproof, moisture and other wood or compound synthesis of a kind of wood plate material. Is the logs from the vertical saw the plate and square material collectively. 2, which, after processing, the width is greater than 3 times the thickness of the known as the plate, the width of less than or equal to 3 times the thickness of the material for the Fang. 3, board Fang material is furniture manufacturing, civil engineering and other commonly used materials.

- Q: So steel products can be called steel, plates and profiles are steel classification.

- So steel products can be called steel, plates and profiles are steel classification. Plate by thickness in the plate, sheet, plate and plate. Separate the plates by the process. Cold plate, hot plate and so on. Profiles, as the name suggests, angle, groove just belong to the profile.

- Q: Now young people who like wood color ah, but the Chinese ah, understand the wood are very old-fashioned, including the designer in the class. The The wood is divided into two one is solid wood, one is garbage wood are labeled as small sand, together with the pressure may be different. The The Speaking of low on these two types of solid wood board is equal to two pressure into the plate on the market,

- Putty scratched polished, and then paint on it, can not brush the effect of white paint spray with a good brush out of the effect!

- Q: Plate and line joints at the crack causes, with morning sun water paint can improve it

- I can use the morning sun water-based wood paint, like a wooden furniture clothes, not only cleverly cover up the wood surface of the insects, knots, color and other defects, but also to highlight the beautiful texture of wood, while Play the role of protection of wood. Recommend you try, very safe

- Q: Do not understand why this size? What is the convenience?

- This is often said that four or eight feet specifications. Where the foot is feet, 1 foot = 0.3048 meters, So four or eight feet is 1.2192 meters x2.4384 meters, Which is nearly equal to 1220x2440mm.

- Q: How about the environmental protection grade of the furniture sheet? What is the effect on the furniture?

- Most of the MDF panels are used for the production of plate furniture, the appearance of beautiful, large manufacturers fine workmanship, good edge, you can achieve relatively environmentally friendly, most manufacturers of plate furniture joints closed bad, resulting in formaldehyde pollution, and can not To govern. The following are the same as the " The following are the same as the " Blockboard veneer furniture manufacturers also said that solid wood furniture, but the wood contains a large number of free formaldehyde, the same will cause formaldehyde pollution, the other surface paint will cause paint pollution. Such furniture surface paint to go through a period of time volatile, harmful things will be smaller. The following are the same as the " Pure solid wood furniture made of raw materials, no free formaldehyde pollution, if the surface with water-based wood paint construction, can eliminate paint pollution, so that furniture can be called real environmental furniture! The following are the same as the " Tip: furniture pollution is mainly due to the free form of formaldehyde in the sheet and the surface of the paint to distribute a lot of benzene, toluene, xylene, TVOC, etc., water-based paint with solvent-based wood paint is different water-based paint is water as solvent PU resin is evenly dispersed in water rather than soluble in water, water evaporation between the resin since the cross-linked film), diluted with water construction. Is a non-toxic, tasteless, non-combustible, safe, environmentally friendly paint. With the water-based paint (non-toxic and tasteless) in the production of furniture on the application of environmentally friendly furniture will be closer to us!

- Q: What are the harmful substances that man-made panels will release?

- Or the purchase of furniture used in the high-density fiberboard. These man-made sheet is the culprit leading to excessive indoor gas pollution. According to expert panel experts, the market of man-made sheet, the general use of urea-formaldehyde resin, in the use of the environment will release formaldehyde. And some poor quality, cheap big core board and other man-made sheet there is unreasonable use of plastic, so that the use of the release of a large number of formaldehyde, polluting the environment. ■ new house decoration must pay attention to the choice of decoration materials, try to use non-toxic and less toxic materials; preferably with green home improvement experience in the home improvement company construction, delivery requirements to provide indoor air quality testing report. ■ When buying furniture, pay attention to the formaldehyde and benzene release of furniture, the new furniture is best ventilation for some time, so that furniture in the release of harmful gases as soon as possible. ■ wood-based panel made of wardrobe must pay attention to, try not to underwear, pajamas on the inside. ■ fabric sofa should not only pay attention to the fabric, but also pay attention to the filler and the adhesive there is no pollutants. Can be used to reduce the indoor toxic gas effective air purification device, furniture to take some effective purification measures and materials, such as adsorption wardrobe in the adsorption of formaldehyde and so on.

Send your message to us

EASY-CLEANING PREPAINTED STEEL COIL FOR COLD ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords