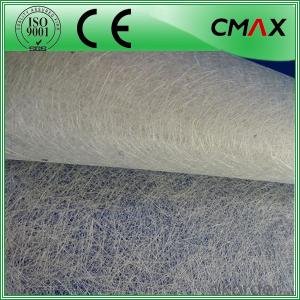

Fiberglass Chopped Strand Insulation Material Fiber Glass Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

Product Features:

Fast breakdown in styrene

Fiber dispersed evenly

Low binder content

Superior acid corrosion resistance

Specifications:

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Product Packaging:

Each Surface Tissue is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 330mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Product Storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

- Q: Aluminum paste carbon fiber glass fiber pulp slurry canoeing and what is the difference between what are the benefits of

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, with glass balls or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron. The equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments. Generally, as the reinforcing material in composite materials, electrical insulation materials and insulation materials, circuit boards and so on, are widely used in various fields of Yu Guomin's economy. Glass fiber is glass drawing, and then made a variety of products, such as glass fiber cloth, glass fiber, cotton, etc., can be used for glass fiber reinforced plastic production, insulation, fire protection, insulation and other aspects, such as ovens, refrigerators, appliances and so on. It can also be used for sports equipment, such as golf clubs, skateboards, surfing boards and so on.

- Q: Can fiberglass chopped strand be used in acoustic insulation applications?

- Yes, fiberglass chopped strand can be used in acoustic insulation applications. Fiberglass is known for its excellent sound absorption properties, making it an ideal material for reducing noise and improving acoustics in various settings. The chopped strand form of fiberglass can be easily mixed with other materials, such as binders or resins, to create insulation products that effectively absorb and dampen sound waves. These products are commonly used in buildings, automotive applications, and other environments where noise reduction is desired. Overall, fiberglass chopped strand is a versatile and effective material for acoustic insulation applications.

- Q: How is the surface treatment of fiberglass chopped strand done?

- The surface treatment of fiberglass chopped strand is typically done through a process called sizing. Sizing involves applying a chemical coating to the strands to improve their adhesion to resins or other materials during manufacturing. This treatment helps enhance the overall strength and performance of fiberglass composites.

- Q: Is fiberglass chopped strand suitable for sports equipment manufacturing?

- Yes, fiberglass chopped strand is suitable for sports equipment manufacturing. It provides excellent strength, durability, and lightweight properties, making it ideal for producing sports equipment such as hockey sticks, bicycles, and tennis rackets. The fiberglass reinforcement enhances the performance and longevity of the sports equipment, making it a popular choice in the industry.

- Q: Does fiberglass chopped strand improve the vibration damping properties of composite materials?

- Yes, fiberglass chopped strand can improve the vibration damping properties of composite materials. Fiberglass has inherent damping properties due to its viscoelastic nature, which means it can absorb and dissipate energy when subjected to vibrations. When used as a reinforcement in composite materials, the fiberglass chopped strand enhances the overall damping characteristics of the composites. The random orientation and short length of the chopped strands allow for them to be dispersed throughout the composite matrix, creating an interlocking network that helps to dissipate vibration energy. This interlocking network effectively hinders the propagation of vibration waves, reducing their amplitude and frequency. As a result, the composite material exhibits improved vibration damping properties. Additionally, the high strength and stiffness of fiberglass further contribute to the overall performance of the composite material. By reinforcing the matrix, the fiberglass chopped strand increases the rigidity of the composite, which helps to minimize the magnitude of vibrations. This combination of damping and reinforcement properties makes fiberglass chopped strand an excellent choice for applications where vibration damping is desired. It is important to note that the specific improvement in vibration damping properties may vary depending on the composition and design of the composite material, as well as the amount and distribution of the fiberglass chopped strand. Proper selection and incorporation of the chopped strand are crucial for achieving the desired vibration damping characteristics in composite materials.

- Q: What does glass fiber do?

- It is a kind of excellent inorganic non-metallic materials, having the advantages of good insulation, good corrosion resistance, which is equivalent to a piece of hair. It is founding by high temperature with the raw materials of glass ball and waste glass. It has the advantages of high mechanical strength, electrical insulating and thermal insulation and heat resistance. Each bundle of fibers is made of hundreds or even thousands of root filaments. The diameter range from several microns to twenty micron.

- Q: What does the fiberglass operated tool body do?

- The roving of roving is made up of parallel filament or parallel monofilament. According to the composition of glass, roving can be divided into alkali free glass roving and medium alkali glass roving. Glass fiber used for producing glass roving is 12~23 m in diameter. Roving the number from 150 to 9600 (Tex). Roving can be directly used for some composite molding methods, such as winding, pultrusion process, because of its uniform tension, can also be woven roving fabric, in certain applications will also be further chopped rovings.

- Q: What are the typical hardness properties of fiberglass chopped strand composites?

- The hardness properties of fiberglass chopped strand composites can vary depending on their specific composition and manufacturing process. However, fiberglass composites are generally known for their excellent hardness properties. Fiberglass chopped strand composites typically have a high level of hardness due to the reinforcing glass fibers. These fibers are typically embedded in a matrix material, such as resin, which adds strength and stability to the composite. The hardness of fiberglass chopped strand composites is often measured using the Rockwell hardness scale or the Vickers hardness test. These tests assess how resistant the material is to indentation or penetration by a harder material. Several factors influence the hardness properties of fiberglass chopped strand composites, including the length and orientation of the glass fibers, the type of resin used, and the overall ratio of fibers to resin. Generally, longer and more aligned fibers contribute to increased hardness. Fiberglass composites are widely used in industries like automotive, aerospace, construction, and marine due to their exceptional hardness properties. They offer excellent resistance to abrasion, impact, and deformation, making them suitable for applications that require durability and strength. It's worth noting that the specific hardness properties of fiberglass chopped strand composites can vary depending on the application requirements and manufacturing process. Therefore, it's advisable to consult the manufacturer or conduct specific tests to determine the exact hardness properties of a particular fiberglass chopped strand composite.

- Q: How is the interlaminar shear strength of fiberglass chopped strand composites determined?

- The interlaminar shear strength of fiberglass chopped strand composites is typically determined through various testing methods, such as the short beam shear test or the double cantilever beam test. These tests involve applying a shear force to the composite material and measuring the maximum load it can withstand before failure. This provides valuable information on the composite's resistance to interlayer shear stresses and helps in evaluating its overall mechanical properties.

- Q: Can fiberglass chopped strand be used in construction applications?

- Fiberglass chopped strand finds extensive use in construction applications. It serves as a reinforcement component in diverse construction products like concrete, asphalt, and composites. By blending the chopped strands with other substances, their strength, durability, and resistance against impact, heat, and corrosion are significantly enhanced. Moreover, fiberglass chopped strand is employed for insulation purposes in construction, effectively providing both thermal and sound insulation properties. In conclusion, fiberglass chopped strand is a flexible and economical material suitable for a broad spectrum of construction applications.

Send your message to us

Fiberglass Chopped Strand Insulation Material Fiber Glass Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords