Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

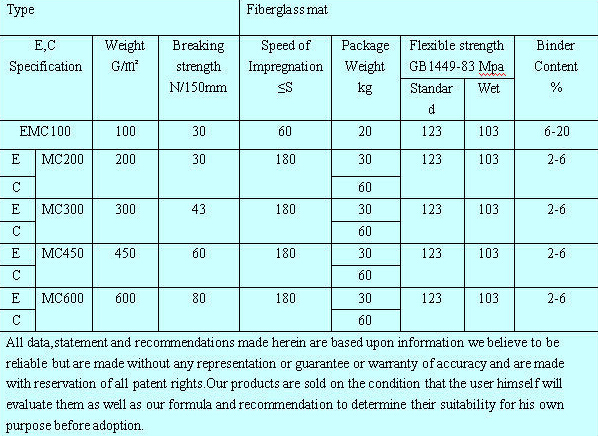

.The Style including the EMC100,EMC200,EMC600.EMCL600.EMCL450,CMC300.CMC450....

2.General width 1040mm/1270mm

3.chopped strand mat is made of randomly dispersed with power or emulsion bonded.

4.Applicable for hand lay -up ,continuous lamination process,compatible with UP VE

5.Suitable for transparent panels,ship ,bodies,automobile parts and interior decorations....

Style :

Packing :

each roll is packed by polyester bag .

2.Every roll in a cardbord box or thhr plastic woven bag

3.30kg with a rollof woven roving

4.Bordbox size : 22*24*114cm

5.The details as per customes requriments

- Q: What are the typical fillers used with fiberglass chopped strand?

- Fiberglass chopped strand usually incorporates fillers like calcium carbonate, talc, mica, and different powders. These fillers are included in the manufacturing process to enhance specific traits of the fiberglass composite. Calcium carbonate is often utilized to augment the stiffness and strength of the composite, while talc is employed to enhance its impact resistance and dimensional stability. Mica fillers are commonly added to heighten the electrical and thermal insulation properties of the fiberglass composite. Furthermore, various types of powders, such as glass microspheres or silica, can be utilized as fillers to decrease density and improve the overall performance of the fiberglass composite. The selection of filler depends on the desired properties and requirements of the final product.

- Q: Can fiberglass chopped strand be used in the production of electrical connectors?

- Yes, fiberglass chopped strand can be used in the production of electrical connectors. It is commonly used as a reinforcement material in plastic molding processes, providing added strength and durability to the connectors.

- Q: Two-way stretch plastic geogrid

- High-intensity Geonet, Geotextile, Uniaxial Plastic Geogrid, Steel-plastic composite Geogrid, Composite geomembrane, and two double to the grid line, Maree Modoo axial loom, Fiberglass geogrid, Polyester geogrid, Geonet, two one-way grille production line, Dornier loom.

- Q: Is fiberglass chopped strand water-resistant?

- Yes, fiberglass chopped strand is water-resistant.

- Q: Is chopped glass fiber harmful to people?

- As reinforcing materials, glass fibers have the following characteristics, which make fiberglass far more widely used than other kinds of fibers and develop far ahead of their characteristics:(1) high tensile strength and small elongation (3%).(2) high elasticity and good rigidity.(3) the elongation within the elastic limit is large and the tensile strength is high, so the impact energy is large.(4) for inorganic fiber, with non flammable, chemical resistance.(5) water absorption is small.(6) the scale stability and heat resistance are excellent.(7) good processability, can be used as stock, bundle, felt, weaving and other forms of products.(8) transparent and permeable to light(9) the development of surface treatment agents with good resin properties.

- Q: How does the orientation of fiberglass chopped strand affect its strength?

- The orientation of fiberglass chopped strand significantly affects its strength. When the strands are aligned in the direction of the applied load, the strength is maximized, as the fibers can bear the load effectively. Conversely, when the strands are randomly oriented, the strength decreases as the load is distributed unevenly among the fibers. Therefore, proper alignment and orientation of fiberglass chopped strand are crucial in maximizing its strength.

- Q: Does fiberglass chopped strand have any antistatic properties?

- No, fiberglass chopped strand does not have any antistatic properties.

- Q: Is fiberglass chopped strand suitable for applications requiring high weather resistance?

- When it comes to high weather resistance, fiberglass chopped strand isn't the best choice. Although fiberglass is known for being strong and durable, chopped strand fiberglass lacks the necessary qualities to withstand harsh weather conditions for an extended period of time. Chopped strand fiberglass is commonly used in applications where mechanical strength is the main requirement, such as automotive parts, pipes, and boat hulls. However, it isn't designed to handle UV radiation, extreme temperature changes, or prolonged exposure to moisture and chemicals. If you need a material that can withstand harsh weather conditions, it's better to consider other options like reinforced plastics, specialty coatings, or composites with enhanced weatherability properties. These materials are specifically engineered to endure sunlight, temperature fluctuations, and moisture, ensuring long-lasting durability and performance in outdoor environments. To ensure high weather resistance, it's important to evaluate the specific requirements of your application and seek advice from experts or manufacturers. They can help determine the most suitable materials to achieve the level of weather resistance you need.

- Q: Make 0.3 mm glass fiber short cut. What kind of fiberglass yarn is good?

- The glass is made of glass fiber chopped after melting, with high-speed airflow or flame blow it into thin and short fiber, which became a moisture-proof glass wool. Superfine glass wool, more than 200 together only a hair so rough. Glass cotton has strong thermal insulation properties. 3 cm thick glass wool insulation, its ability to compete is equivalent to 1 meters thick brick! Glass wool sound-absorbing effect is also very good. So it is used as insulation, in many industrial sectors in sound insulation, heat insulation, shockproof and filtration materials.

- Q: Can fiberglass chopped strand be used in chemical pipelines?

- Using fiberglass chopped strand in chemical pipelines is not advisable. Fiberglass lacks chemical resistance and can degrade when exposed to certain chemicals. To ensure the safe transport of chemicals in pipelines, it is recommended to employ materials tailored for this purpose, such as corrosion-resistant alloys or lined pipes. The utilization of fiberglass chopped strand may result in leaks, contamination, and potential hazards within the pipeline system.

Send your message to us

Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords