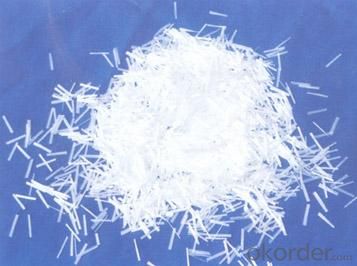

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What are the packaging options for fiberglass chopped strand?

- The packaging options for fiberglass chopped strand typically include bulk bags, cardboard boxes, and plastic bags.

- Q: Can fiberglass chopped strand be used in the production of electrical connectors?

- Yes, fiberglass chopped strand can be used in the production of electrical connectors. Fiberglass chopped strand is a type of reinforcing material that is made from chopped fiberglass strands. It is commonly used in various industries, including electrical and electronics, due to its excellent electrical insulation properties. Electrical connectors are used to join electrical circuits together, and it is important for them to have good electrical insulation to prevent any electrical leakage or short circuits. Fiberglass chopped strand provides excellent electrical insulation properties, making it a suitable material for use in the production of electrical connectors. Additionally, fiberglass chopped strand is also known for its mechanical strength, chemical resistance, and durability. These properties make it ideal for use in applications where the connectors may be subjected to harsh environments or require high mechanical performance. Furthermore, fiberglass chopped strand can also be easily molded into different shapes and sizes, allowing for the production of connectors with complex designs. This flexibility in design makes fiberglass chopped strand a versatile material for the production of electrical connectors. In conclusion, fiberglass chopped strand can indeed be used in the production of electrical connectors due to its excellent electrical insulation properties, mechanical strength, chemical resistance, durability, and flexibility in design.

- Q: Can fiberglass chopped strand be used in high temperature applications?

- No, fiberglass chopped strand is not suitable for high temperature applications as it has a low melting point and can degrade when exposed to high temperatures.

- Q: What are the typical surface preparation techniques for fiberglass chopped strand composites?

- Surface preparation techniques for fiberglass chopped strand composites typically involve a series of steps to ensure proper bonding and adhesion of the composite material. To begin with, the surface of the composite needs to be cleaned in order to eliminate any dirt, dust, oils, or contaminants that may be present. This can be achieved by employing solvents or detergents, followed by a thorough rinsing and drying of the surface. Once the cleaning process is completed, the next step involves roughening or abrasion of the surface. This is typically accomplished by using sandpaper, abrasive pads, or a sanding machine. The purpose of this step is to create a rough surface profile that enhances the mechanical interlocking between the composite material and the substrate. Following the roughening process, it is crucial to eliminate any dust or debris that may have been generated. This can be achieved by either blowing compressed air or using a vacuum to clean the surface. After the surface has been roughened and cleaned, the subsequent step entails applying a suitable primer or surface treatment. The choice of primer or treatment depends on the specific requirements and compatibility with the composite material. Primers assist in enhancing adhesion and creating a barrier against moisture or other environmental factors. They can be applied using brushes, rollers, or spray equipment. Once the primer or treatment has been applied, it must be allowed to dry or cure according to the manufacturer's instructions. This ensures that the surface is ready for the final step, which involves the application of the chopped strand composite. It is important to note that the specific surface preparation techniques may vary depending on the type of fiberglass chopped strand composite and its intended application. Manufacturers or suppliers of the composite material usually provide detailed instructions and guidelines for surface preparation, which should be followed for optimal results.

- Q: How does the fiber orientation impact the properties of chopped strand composites?

- The properties of chopped strand composites are significantly influenced by the orientation of the fibers. Conventionally, short fibers are dispersed randomly in a matrix material to create chopped strand composites. The mechanical properties, including strength, stiffness, impact resistance, and overall performance of the composite material, are greatly impacted by the arrangement of these fibers. The load-bearing capability of a chopped strand composite depends on the orientation of the fibers. When the fibers are aligned with the applied load, they bear the majority of the stress, leading to enhanced strength and stiffness in that particular direction. Conversely, fibers oriented perpendicular to the load have limited capacity to bear the load, resulting in weaker properties in that direction. Additionally, the fiber orientation also affects the anisotropic behavior of the composite. Anisotropic materials exhibit different properties in different directions, and the degree of anisotropy is determined by the fiber orientation. When the fibers are randomly oriented, the composite demonstrates more isotropic behavior, meaning the properties are relatively similar in all directions. However, if the fibers are aligned, the composite becomes more anisotropic, with properties varying significantly depending on the direction of loading. The fiber orientation also has an impact on the impact resistance of chopped strand composites. Fibers aligned in the direction of impact effectively absorb and distribute the energy, enhancing the impact resistance of the composite. Conversely, fibers oriented perpendicular to the impact direction may not effectively absorb the energy, making the composite more vulnerable to damage. In conclusion, the fiber orientation plays a critical role in determining the properties of chopped strand composites. Manufacturers can optimize the strength, stiffness, impact resistance, and anisotropy of the material by controlling the alignment of the fibers, thereby tailoring the composites to meet specific application requirements and enhancing their overall performance.

- Q: Is fiberglass chopped strand suitable for applications requiring high weather resistance?

- Fiberglass chopped strand is generally not suitable for applications requiring high weather resistance. While fiberglass is known for its excellent strength and durability, chopped strand fiberglass lacks the necessary properties to withstand prolonged exposure to harsh weather conditions. Chopped strand fiberglass is typically used in applications where mechanical strength is the primary requirement, such as automotive parts, pipes, and boat hulls. However, it is not designed to withstand UV radiation, extreme temperature variations, or prolonged exposure to moisture and chemicals. For applications requiring high weather resistance, other materials such as reinforced plastics, specialty coatings, or composites with enhanced weatherability properties are more suitable. These materials are specifically engineered to withstand the effects of sunlight, temperature fluctuations, and moisture, ensuring long-term durability and performance in outdoor environments. It is important to assess the specific requirements of the application and consult with experts or manufacturers to determine the most suitable materials for achieving high weather resistance.

- Q: How does the fiber length of fiberglass chopped strand affect its performance?

- The fiber length of fiberglass chopped strand plays a significant role in determining its performance. Longer fibers in chopped strand provide several advantages over shorter fibers. Firstly, longer fibers enhance the mechanical properties of the fiberglass composite. Longer fibers offer improved strength and stiffness, making the composite material more resistant to deformation and capable of withstanding higher loads. This results in a stronger and more durable final product. Secondly, longer fibers improve the interfacial bonding between the fiber and the matrix material. The longer fibers provide a larger contact area with the matrix, allowing for better stress transfer between the two components. This improved bonding enhances the overall performance of the composite by increasing its ability to resist crack propagation and delamination. Additionally, longer fibers can improve the impact resistance of the fiberglass composite. The longer fibers act as reinforcements, absorbing and distributing the energy generated during impact events. This helps prevent cracks from propagating and enhances the material's ability to withstand sudden forces. However, it is important to note that there is an optimal fiber length for specific applications. Longer fibers may not always be advantageous, as they can increase the viscosity of the resin and make it more challenging to process. Moreover, longer fibers may be less effective in applications that require good flowability or where the composite needs to conform to complex shapes. In conclusion, the fiber length of fiberglass chopped strand significantly influences its performance. Longer fibers contribute to improved mechanical properties, better interfacial bonding, and enhanced impact resistance. However, the optimal fiber length should be carefully determined based on the specific requirements of the application to balance performance with processability.

- Q: What are the peel strength properties of fiberglass chopped strand?

- The peel strength properties of fiberglass chopped strand refer to its ability to resist delamination or separation between the strands and the matrix material in a composite structure. These properties are important in determining the overall strength and durability of the composite material. The peel strength of fiberglass chopped strand is influenced by various factors including the type and quality of the matrix material, the length and diameter of the strands, the orientation of the strands, and the manufacturing process used. Fiberglass chopped strand typically exhibits good peel strength due to its high tensile strength and bonding capability with different matrix materials such as thermoset resins, thermoplastics, and cementitious materials. The strands are designed to provide excellent adhesion and mechanical interlocking with the matrix, resulting in strong bonding between the fibers and the surrounding material. The peel strength properties can be further enhanced by using appropriate surface treatments on the strands, such as silane coupling agents, to improve their compatibility with the matrix material and promote better adhesion. It is important to note that the peel strength properties of fiberglass chopped strand can vary depending on the specific application and the requirements of the composite structure. Therefore, it is recommended to consult the manufacturer or conduct specific peel strength tests to determine the exact properties of the material for a particular application.

- Q: What is the cost of fiberglass chopped strand compared to other materials?

- The cost of fiberglass chopped strand compared to other materials can vary depending on several factors such as the quality, quantity, and supplier. However, in general, fiberglass chopped strand is considered to be a relatively cost-effective material compared to other alternatives. Compared to materials like carbon fiber or aramid (Kevlar), fiberglass chopped strand is typically more affordable. This is because the production process of fiberglass is less complex and less costly. Additionally, fiberglass chopped strand is widely available and has a large market share, which helps keep the prices competitive. In comparison to traditional materials like steel or aluminum, fiberglass chopped strand can also offer cost advantages. Fiberglass is generally lighter in weight, which can reduce transportation and installation costs. It is also corrosion-resistant, eliminating the need for additional coatings or treatments to prevent rust or degradation. Furthermore, fiberglass chopped strand offers excellent strength-to-weight ratios, making it a cost-effective choice for applications where high strength and durability are required. It is important to note that while fiberglass chopped strand may have a relatively lower upfront cost compared to some materials, the overall cost-effectiveness depends on the specific application, performance requirements, and long-term maintenance considerations. Conducting a thorough cost analysis and considering factors beyond the initial purchase price is essential in determining the true cost of using fiberglass chopped strand compared to other materials.

- Q: What is electroplate glass fiber cloth

- Leather, silicone, plating, red twill, the largest area can produce 1000mm * 500mm carbon fiber board (color carbon fiber board)

Send your message to us

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords