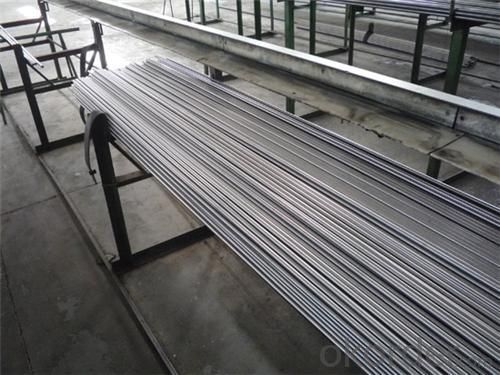

durable and Reliable sus 309 stainless steel bar with quick delivery made in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for HVAC systems?

- Yes, stainless steel pipes can be used for HVAC systems. Stainless steel is a durable and corrosion-resistant material that is suitable for various applications, including HVAC systems. It offers excellent strength and reliability, making it an ideal choice for transporting fluids and gases in HVAC systems. Additionally, stainless steel pipes can withstand high temperatures and maintain their integrity, ensuring efficient and long-lasting performance in HVAC installations.

- Q: What is the difference between 316 and 316LN stainless steel pipes?

- The main difference between 316 and 316LN stainless steel pipes lies in their nitrogen content. 316LN stainless steel pipes have a higher nitrogen content, which enhances their resistance to corrosion and improves their strength and toughness. This makes 316LN stainless steel pipes suitable for applications in more demanding environments, such as those involving high temperatures and aggressive chemicals.

- Q: How do you calculate the deflection of stainless steel pipes under load?

- To determine the deflection of stainless steel pipes under load, one can employ the theory of beam bending. This involves analyzing the pipe as a beam and applying the principles of bending moment and deflection. Initially, the moment of inertia (I) of the stainless steel pipe must be ascertained. This can be accomplished by utilizing a formula specific to the shape of the pipe. For instance, in the case of a circular pipe, the formula is as follows: I = π * (D^4 - d^4) / 64, where D represents the outer diameter and d represents the inner diameter of the pipe. Subsequently, the bending moment (M) acting on the pipe needs to be calculated. This is typically obtained from the applied load, which may take the form of a force, pressure, or weight acting on the pipe. The bending moment can be determined by multiplying the load by the distance between the applied load and the point of interest on the pipe. Once the moment of inertia (I) and bending moment (M) are known, the maximum deflection (δ) can be calculated using the following formula: δ = (M * L^2) / (E * I), where L represents the span length of the pipe and E represents the modulus of elasticity for stainless steel. It is crucial to note that these calculations assume the stainless steel pipe possesses perfect elasticity and a uniform material composition. Real-world factors, such as material properties, pipe geometry, and boundary conditions, may impact the accuracy of the computed deflection. Therefore, it is advisable to consult pertinent engineering codes, standards, or professional resources to ensure precise and safe calculations.

- Q: What are the advantages of using stainless steel pipes in the oil and gas industry?

- There are several advantages of using stainless steel pipes in the oil and gas industry. Firstly, stainless steel pipes have excellent corrosion resistance, which makes them highly durable and reliable in harsh environments. This resistance to corrosion helps in preventing leaks and ensures the longevity of the pipes, reducing maintenance and replacement costs. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them suitable for transporting oil and gas without the risk of failure. They also have excellent mechanical properties and are able to withstand impacts and vibrations, ensuring the integrity of the pipelines. Furthermore, stainless steel pipes have good hygiene properties, as they are resistant to bacteria and can be easily cleaned, which is crucial in industries where contamination is a concern. Overall, the use of stainless steel pipes in the oil and gas industry offers increased safety, cost-effectiveness, and reliability.

- Q: Are stainless steel pipes suitable for cryogenic applications?

- Stainless steel pipes are indeed suitable for cryogenic applications due to their exceptional low-temperature properties. This material proves to be an ideal choice when dealing with extremely cold temperatures in cryogenic applications. Its impressive strength, outstanding resistance to corrosion, and commendable thermal conductivity are all crucial factors when handling cryogenic fluids or gases. The structural integrity and durability of stainless steel pipes remain intact even under the harshest cold conditions, avoiding any brittleness. Moreover, the ability of stainless steel to resist expansion and contraction ensures consistent and dependable performance in cryogenic environments. Hence, it is no wonder that stainless steel pipes have gained popularity in various industries like aerospace, medical, and energy where cryogenic applications are commonly encountered.

- Q: Mirror stainless steel tube 60*60 how much is one meter?

- Stainless steel tube square weight formula: (pipe circumference / 3.14- actual thickness) * actual thickness *0.02491* length, 0.02491 of which is converted by the stainless steel density of a constant.

- Q: How do you calculate the maximum allowable span for stainless steel pipes?

- To calculate the maximum allowable span for stainless steel pipes, you need to consider several factors, including the pipe's material properties, dimensions, and the applied load. First, determine the material properties of the stainless steel pipe, such as its yield strength, ultimate tensile strength, and the modulus of elasticity. These values can usually be obtained from the manufacturer's specifications or engineering handbooks. Next, identify the dimensions of the pipe, particularly its outside diameter and wall thickness. These measurements are crucial in determining the pipe's moment of inertia, which affects its ability to resist bending. Once you have these values, you can apply the appropriate formula or calculation method based on the type of load the pipe will be subjected to. There are different calculations for uniformly distributed loads, concentrated loads, or a combination of both. For example, if the load is uniformly distributed along the span, you can use the formula for maximum deflection or sag, which takes into account the pipe's modulus of elasticity, moment of inertia, applied load, and the span length. However, if the load is concentrated at specific points, you may need to consider the maximum bending stress. This calculation involves determining the bending moment, which depends on the load, span length, and the pipe's moment of inertia. You can then compare this bending stress with the pipe's yield strength to ensure it does not exceed the allowable limit. It is important to note that different codes and standards may provide specific guidelines for calculating the maximum allowable span for stainless steel pipes. Therefore, it is advisable to consult relevant industry standards or consult with a qualified engineer to ensure accurate calculations and compliance with safety regulations.

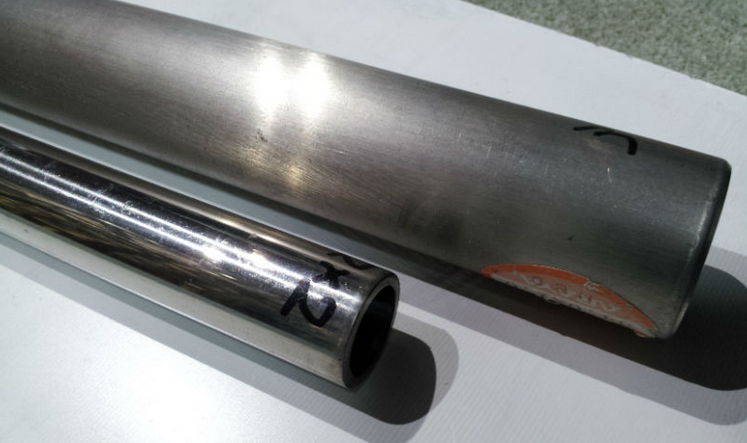

- Q: What is the difference between 304 and 304L stainless steel pipes?

- The main difference between 304 and 304L stainless steel pipes is the carbon content. 304L has a lower carbon content, which makes it more suitable for welding applications as it reduces the risk of carbide precipitation and subsequent corrosion. Additionally, this lower carbon content also enhances the resistance to sensitization during heat treatment processes.

- Q: Are stainless steel pipes suitable for pulp and paper industries?

- Yes, stainless steel pipes are suitable for pulp and paper industries. They are resistant to corrosion, heat, and chemicals, making them ideal for transporting corrosive and abrasive fluids commonly found in these industries. Stainless steel pipes also have high strength and durability, ensuring long-term performance in demanding environments.

- Q: Are stainless steel pipes suitable for fertilizer production?

- Yes, stainless steel pipes are suitable for fertilizer production. Stainless steel is highly resistant to corrosion, which is particularly important in fertilizer production as fertilizers often contain corrosive substances. Additionally, stainless steel pipes are durable, hygienic, and can withstand high temperatures and pressures, making them ideal for the demanding conditions of fertilizer production processes.

Send your message to us

durable and Reliable sus 309 stainless steel bar with quick delivery made in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords