DUCTILE IRON PIPES AND PIPE FITTINGS K9 CLASS DN80

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material : Ductile Cast Iron

Size Range : DN 80mm to DN 2000mm

Unit Effective Length : 6m or 5.7m

Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

Annual capacity : 200,000 tons

Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

Special requirements on external coating and internal lining can be applied

We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Additional Parts:

Each pipe is strictly inspected according to related standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering you a competitive price.

A copy of original inspection reports of pipes will be offered after shipment.

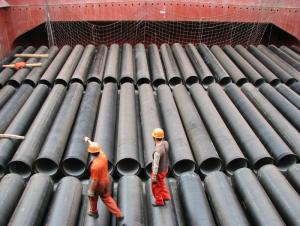

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis.

- Q: Can ductile iron pipes be used in acidic environments?

- Ductile iron pipes are capable of being utilized in acidic environments. These pipes possess a strong resistance to corrosion, rendering them suitable for a wide range of applications, including those involving acidic conditions. The heightened carbon content found in ductile iron pipes generates a shielding layer on the pipe's surface, effectively thwarting direct attacks from acid on the iron. Furthermore, the interior lining of the pipe can be coated with epoxy or other protective substances to bolster its resistance to corrosion in acidic settings. Nevertheless, it is crucial to take into account the precise concentration and type of acid present within the environment, as certain acids may still induce corrosion over time. It is highly recommended to seek counsel from professionals or manufacturers to ensure the appropriate selection of materials for specific acidic conditions.

- Q: Can ductile iron pipes be recycled?

- Indeed, it is possible to recycle ductile iron pipes. Ductile iron, a form of cast iron, possesses exceptional strength and endurance, rendering it a favored selection for numerous purposes, such as water and sewage pipelines. Once these pipes have surpassed their useful lifespan, they can undergo recycling and be transformed into fresh merchandise. The recycling procedure comprises the fusion of the ductile iron pipes to extract the iron, subsequently serving as a raw material for the creation of novel ductile iron goods. By recycling ductile iron pipes, not only do we conserve natural resources, but we also diminish the environmental impact associated with mining and the production of new substances.

- Q: What is the typical cost of maintenance for ductile iron pipes?

- The typical cost of maintenance for ductile iron pipes can vary depending on several factors. These factors include the age and condition of the pipes, the location and accessibility of the pipes, and the specific maintenance requirements. In general, regular maintenance activities for ductile iron pipes may include cleaning and flushing to remove sediment and debris, inspecting for leaks or cracks, repairing or replacing damaged sections, and applying protective coatings to prevent corrosion. These maintenance tasks are essential to ensure the longevity and performance of the pipes. The cost of maintenance for ductile iron pipes can range from a few hundred dollars to several thousand dollars per year, depending on the extent of maintenance required. Routine maintenance activities such as cleaning and inspection may have lower associated costs, while more significant repairs or replacements can be more expensive. Additionally, the cost of maintenance can be influenced by external factors such as labor costs, materials, and contractor fees. It is crucial to consider these factors and consult with professionals or utility companies for accurate cost estimates specific to your location and situation. Overall, while the cost of maintenance for ductile iron pipes can vary, investing in regular maintenance is essential to extend the lifespan and functionality of the pipes, minimize disruptions, and prevent costly repairs or replacements in the long run.

- Q: Can ductile iron pipes be used for conveying gases?

- Indeed, gases can be conveyed using ductile iron pipes. Ductile iron, renowned for its strength and durability, is capable of enduring high pressures and temperature fluctuations, rendering it appropriate for gas transportation. Furthermore, ductile iron pipes possess exceptional resistance to corrosion, a crucial attribute when handling potentially corrosive gases. Nevertheless, it is of utmost importance to verify the compatibility between the specific gas being conveyed and ductile iron, in order to avert any chemical reactions or pipe damage. To ensure the secure and efficient conveyance of gases through ductile iron pipes, one must carefully consider proper engineering design and material selection.

- Q: Can cast iron pipes not be used for domestic water supply and drainage?

- Cast iron pipes are mostly used in fire fighting, fire hydrant water supply and indoor water supply. Plastic pipes are used in general and high water riser pipes are made of plastic steel composite pipes

- Q: What is the maximum temperature that ductile iron pipes can handle?

- Ductile iron pipes can handle temperatures up to a maximum of around 1000 degrees Fahrenheit (538 degrees Celsius).

- Q: How do ductile iron pipes handle ground settlement due to construction activities?

- Ductile iron pipes have the ability to handle ground settlement caused by construction activities due to their flexibility and strength. These pipes are designed to withstand external pressure and can accommodate minor ground movements without significant damage or failure. The ductility of the material allows the pipes to deform slightly, absorbing the ground settlement and preventing them from cracking or breaking. Additionally, the joints in ductile iron pipes are typically flexible, allowing for further movement and reducing the risk of leakage or structural issues. Overall, ductile iron pipes are well-suited for withstanding ground settlement and ensuring the integrity of the pipeline system during construction activities.

- Q: How much is the installation cost of the ductile iron tube?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: Which is good for water polo cast iron pipe steel pipe?

- Flexible seamless steel pipe is good toughness, good processing, better than ductile iron corrosion resistance, the price is slightly higher;

- Q: How are ductile iron pipes different from cast iron pipes?

- Ductile iron pipes are different from cast iron pipes in terms of their composition and properties. Ductile iron pipes are made from a type of cast iron that has been treated with magnesium to improve its strength and flexibility. This makes ductile iron pipes more durable, impact-resistant, and less prone to cracking or breaking compared to traditional cast iron pipes. Additionally, ductile iron pipes have a higher tensile strength, allowing them to withstand higher internal and external pressures. In summary, ductile iron pipes are a more modern and advanced version of cast iron pipes, offering improved performance and longevity.

Send your message to us

DUCTILE IRON PIPES AND PIPE FITTINGS K9 CLASS DN80

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords