Ductile Iron Pipe Pull Strength:420 ISO2531 DN500-DN800

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc

spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

2.Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

• Inspection: inspect in house, all our products must be checked 3 times before packing

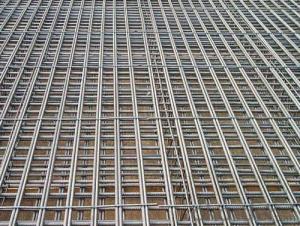

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic

sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing

and On-site assistance

Documentary: MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order,

B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile

iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to

installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable

to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: What are the different types of ductile iron pipe joints?

- There are several types of ductile iron pipe joints, including push-on joints, mechanical joints, restrained joints, flanged joints, and grooved joints.

- Q: What is the typical pressure rating of ductile iron pipes?

- The typical pressure rating of ductile iron pipes ranges from 150 to 350 PSI (pounds per square inch), depending on the diameter and class of the pipe.

- Q: Can ductile iron pipe be used for directional drilling?

- Yes, ductile iron pipe can be used for directional drilling. Directional drilling is a technique used to install underground pipes, cables, and conduits in a curved or horizontal path. Ductile iron pipes are known for their high strength and flexibility, making them suitable for this method. The pipes can be easily bent and maneuvered during the drilling process, allowing for the installation of pipelines in challenging terrains or crossing obstacles such as rivers, highways, and buildings. Additionally, ductile iron pipes have excellent resistance to corrosion, making them a durable and reliable choice for directional drilling projects.

- Q: What are the different methods for repairing ductile iron pipe?

- There are several methods for repairing ductile iron pipe, including mechanical repair, epoxy repair, and welding. Mechanical repair involves using clamps or couplings to seal leaks or cracks in the pipe. Epoxy repair involves applying an epoxy coating or sealant to the damaged area to prevent further corrosion or leaks. Welding is another method used for repairing ductile iron pipe, where the damaged section is cut out and replaced with a new piece that is welded into place.

- Q: What are the different sizes of ductile iron pipes available?

- The sizes of ductile iron pipes available vary depending on the specific needs and requirements of a project. Common sizes range from 4 inches to 64 inches in diameter, with larger sizes also available for specialized applications.

- Q: What is the relationship between the direction of the spigot and the direction of the flow in the ductile iron pipe?

- Use more than 18 casting molten iron, by adding the spheroidizing agent, through the centrifugal ductile iron machine high-speed centrifugal casting pipe

- Q: Can ductile iron pipes be used in gravity sewer systems?

- Ductile iron pipes find great utility in gravity sewer systems. Renowned for their robustness and durability, they are extensively employed in diverse applications, including sewer systems. Boasting exceptional corrosion resistance, they can withstand immense pressure and heavy burdens. Moreover, their flawlessly smooth interior surface curtails friction and enhances the transportation of waste and wastewater. Consequently, they emerge as an ideal option for gravity sewer systems, where the seamless flow of sewage hinges upon gravity to traverse the pipes.

- Q: How can the three pipes of ductile iron leak?

- When the pipe connection of the three water leakage, first of all to see whether it is to do the pipe three links of the manufacturers, pressure did not reach, if it is. It is only the replacement, if not, with cast iron electrode welding, or socket connection half!

- Q: How does ductile iron pipe perform in areas with high seismic activity?

- Ductile iron pipe performs well in areas with high seismic activity due to its inherent flexibility and strength. Its ability to withstand ground movement and absorb seismic forces makes it a reliable choice for underground piping systems in earthquake-prone regions. Additionally, the material's high tensile strength and resilience help it resist fractures and maintain its structural integrity during seismic events, ensuring the continuous flow of water or other fluids.

- Q: What's the difference between ductile iron pipe and cast iron pipe?

- Cast iron pipe and ductile iron pipe, cast iron pipe, also known as the cast iron pipe, ordinary gray iron. Often used in socket connection, the sealing material is usually cement rigid interface.

Send your message to us

Ductile Iron Pipe Pull Strength:420 ISO2531 DN500-DN800

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords