Coil Reasonable Rebar Price Tying Wire for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coil Reasonable Rebar Price Tying Wire for Construction

Description for Coil Rebar

Type | Rebar coil and wire rod |

Steel Grade | HRB400 , HRB500, GR.60, Q235, Q255, Q275, SAE1006, SAE1008 |

Your required chemical composition. | |

Size | 5.5mm-10mm |

Unit weight | 1.6-1.9 Tons/coil |

Application | Building/project construction |

Packing | In coil with steel strip ,in bulk . |

MOQ | 1000tons(500for trial order ). |

Delivery Time | 25days . |

Payment | T/T , West Union , Cash , L/C. |

Trade Terms | FOB, CFR, CIF ,EXW |

Trans terms | FIO FILO FLT |

Loading port | Caofeidian /Jingtang/Tianjin,China |

Datas of Chemical Composition for Coil Rebar

Content | C% | Mn% | Si% | Cr% | Ni% | S% | P% | Cr% |

HRB400 | 0.14-0.22 | 0.40-0.65 | 0.05-0.15 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB400E | 0.14-0.22 | 0.40-0.65 | 0.15-0.30 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB500 | 0.28-0.37 | 0.50-1.00 | 0.05-0.15 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB500E | 0.28-0.37 | 0.50-1.00 | 0.15-0.30 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

FAQ

Why Should You Choose Us:

Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

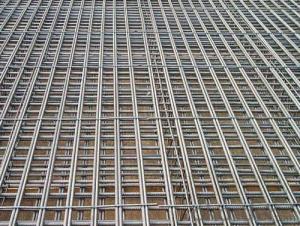

Picture:

- Q: How do ductile iron pipes perform in sandy soil conditions?

- Ductile iron pipes perform well in sandy soil conditions due to their inherent strength and durability. The material's high tensile strength allows it to withstand the pressure exerted by the surrounding soil, preventing pipe deformation and breakage. Additionally, the corrosion resistance of ductile iron ensures a longer lifespan, even in corrosive sandy soil environments.

- Q: How do ductile iron pipes handle pressure surges in pumping stations?

- Ductile iron pipes are specifically designed to handle pressure surges in pumping stations effectively. The inherent strength and flexibility of ductile iron make it well-suited to withstand the sudden increase in pressure that can occur during pump start-up or shutdown. One of the key features of ductile iron pipes is their ability to absorb and dissipate energy. When a pressure surge occurs, the ductile iron pipes have the capacity to absorb the excess pressure and distribute it evenly throughout the pipe network. This helps to minimize the impact of the surge and prevent any potential damage to the pipes or the pumping station. Additionally, ductile iron pipes have a high resistance to impact and stress, which further enhances their ability to handle pressure surges. The pipes are manufactured using a unique process that imparts strength and durability, allowing them to withstand the forces exerted during pressure fluctuations without any significant deformation or failure. Furthermore, ductile iron pipes have a smooth internal surface, which reduces friction and turbulence within the pipe network. This smooth flow characteristic helps to mitigate the effects of pressure surges by allowing the water to move efficiently without creating additional stress on the pipes. In summary, ductile iron pipes are specifically engineered to handle pressure surges in pumping stations by absorbing and dissipating the excess pressure, withstanding the impact and stress, and promoting smooth flow. Their robustness and reliability make them an ideal choice for applications where pressure fluctuations are common, ensuring the longevity and efficiency of the pumping infrastructure.

- Q: Are ductile iron pipes suitable for underground storage tanks?

- No, ductile iron pipes are not suitable for underground storage tanks.

- Q: When the ductile iron pipe is pressed, the three links are always running out. What should be done?

- If the conventional backfill soil pressure, pipe fittings installed properly, the phenomenon will not appear.

- Q: Can ductile iron pipes be used for underground storage of hazardous materials?

- No, ductile iron pipes should not be used for underground storage of hazardous materials. Ductile iron pipes are commonly used for water and sewage systems due to their durability and corrosion resistance. However, they are not designed to withstand the specific requirements and potential hazards associated with storing hazardous materials underground. When it comes to underground storage of hazardous materials, it is crucial to use materials that are specifically engineered to handle the chemical properties and potential risks associated with these substances. Specialized materials such as high-density polyethylene (HDPE) or fiberglass reinforced plastic (FRP) are commonly used for underground storage tanks due to their excellent chemical resistance and ability to maintain structural integrity over time. Using ductile iron pipes for such purposes may lead to corrosion, leaks, or even catastrophic failures, resulting in environmental contamination and potential harm to surrounding areas. Therefore, it is essential to consult with experts and adhere to applicable regulations and guidelines when selecting materials for underground storage of hazardous materials to ensure safety and prevent potential hazards.

- Q: What is the expected bedding and backfill requirements for ductile iron pipes?

- To ensure the longevity and proper functioning of ductile iron pipes, it is crucial to meet the expected bedding and backfill requirements. Although these pipes are known for their durability and strength, careful installation is still necessary to prevent any potential damage or compromised performance. The bedding requirements for ductile iron pipes entail establishing a stable and uniform support system to distribute the loads and stresses from the surrounding soil. The pipe should be surrounded by a bedding material that is devoid of rocks, debris, or any sharp objects that could potentially cause harm. Moreover, the bedding material should be adequately compacted to prevent settlement or shifting, which could result in misalignment or pipe failure. Typically, a granular material such as sand or fine aggregate is employed as the bedding material for ductile iron pipes, with a minimum thickness of 6 inches. This material should be evenly placed beneath and around the pipe to provide a continuous support system. Additionally, it should be compacted to at least 90% of the maximum dry density to ensure proper stability and load distribution. As for the backfill requirements, they pertain to the material used to fill the remaining space around the pipe after the bedding has been installed. Similar to the bedding material, the backfill material should be free from rocks, debris, or sharp objects to prevent damage. It should offer support and protection to the pipe while allowing for proper compaction and settling. The backfill material for ductile iron pipes typically consists of a granular substance such as sand or fine aggregate, with a maximum particle size of 1 inch. It should be placed and compacted in layers, ensuring that the compaction is uniform and even around the pipe. Sufficient compaction is crucial to avoid settlement or shifting of the backfill material, which could potentially harm or misalign the pipe. In conclusion, meeting the expected bedding and backfill requirements for ductile iron pipes necessitates the use of a granular material that is free from rocks, debris, or sharp objects. This material should be evenly placed and compacted to provide stable support and protection to the pipe. Adhering to these requirements will help ensure the proper functioning and longevity of ductile iron pipe systems.

- Q: Are ductile iron pipes suitable for use in hydroelectric dams?

- Hydroelectric dams benefit from the suitability of ductile iron pipes. Ductile iron, a more flexible and stronger type of iron compared to traditional cast iron, is an ideal option for various applications, including water transmission systems in hydroelectric dams. Ductile iron pipes possess durability and resistance to corrosion, which is essential in the continuous water exposure environment of a dam. They can endure high pressures and extreme temperatures, making them fitting for the demanding conditions within hydroelectric dams. Moreover, ductile iron pipes exhibit excellent joint integrity, guaranteeing their leak-proof and reliable performance throughout their lifespan. This aspect is crucial for maintaining the efficiency and effectiveness of a hydroelectric dam's water transmission system. Additionally, ductile iron pipes prove to be cost-effective when compared to materials like steel or concrete. With a long service life, minimal maintenance requirements, and easy availability, they present a practical choice for hydroelectric dam projects. In conclusion, ductile iron pipes are a viable option for hydroelectric dams due to their durability, corrosion resistance, high-pressure tolerance, joint integrity, and cost-effectiveness. They provide the necessary strength and flexibility to efficiently transport water within the dam, contributing to the overall success and longevity of the hydroelectric power generation system.

- Q: Are ductile iron pipes suitable for use in hydropower projects?

- Yes, ductile iron pipes are suitable for use in hydropower projects. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them ideal for carrying water in hydropower projects. Additionally, their ability to withstand high pressure and adaptability to various ground conditions further supports their suitability for such projects.

- Q: Can the sealing ring of ductile iron pipe be reused?

- It is better not to have used things, easy aging, sealed, the best to use new

- Q: Can ductile iron pipes be used in areas with high levels of heavy metal contamination?

- Areas with high levels of heavy metal contamination can indeed utilize ductile iron pipes. Ductile iron, known for its strength and durability, is resistant to corrosion, thus making it ideal for various environmental conditions, including those with heavy metal contamination. The structural integrity and performance of ductile iron pipes remain unaffected by the presence of high levels of heavy metals in the surrounding soil or water. These pipes feature a protective lining, typically made of cement mortar or polyethylene, which acts as a barrier between the pipe and its environment. This lining effectively prevents the leaching of heavy metals into the flowing water. Moreover, ductile iron pipes have demonstrated exceptional resistance to chemical corrosion, including that caused by heavy metals. Consequently, they have been extensively used in industrial settings where heavy metal contamination is prevalent, such as wastewater treatment plants, industrial facilities, and mining sites. However, it is crucial to emphasize the importance of regular monitoring and maintenance for ductile iron pipes, even though they can withstand high levels of heavy metal contamination. These measures ensure that the protective lining remains intact and any potential issues are promptly addressed. In conclusion, ductile iron pipes are a suitable choice for areas with substantial heavy metal contamination. Their strength, durability, and resistance to corrosion make them a reliable option for transporting water and other fluids, even in challenging environments.

Send your message to us

Coil Reasonable Rebar Price Tying Wire for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords