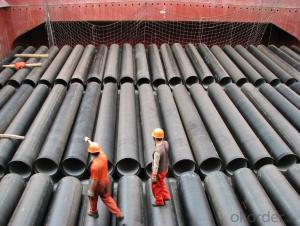

Ductile Iron Pipe DN80 DN100 DN200 K8 K9 K7

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | T type / K type / Flange type |

| Length: | 6m / 5.7m / Negotiable | Standard: | ISO2531 / EN545 / EN598 | Application: | Potable / Sewage water |

| Diameter: | DN80~DN2200 | Shape: | Round | Hardness: | 230 |

| Pipe Wall Thickness: | standard | Pull Strength: | 420 | Yield (≥ MPa): | 300 |

| Material: | Ductile Iron | Type: | Centrifugal ductile cast iron pipe | Certification: | ISO2531 / EN545 / EN598 |

| Outer Diameter: | 80-2200 | Thickness: | standard | Specification: | DN80~DN2200 |

| |

The advantages to the customer:

Trustworthy financial strength.

One-stop shopping.

Fast and efficient service.

Coordination of shipments from multiple plants.

Specialists of the overseas shipping process.

A more competitive price.

- Q: Are ductile iron pipes suitable for installation in areas with high groundwater salinity?

- Areas with high groundwater salinity are generally suitable for the installation of ductile iron pipes. Ductile iron is renowned for its resistance to corrosion, making it a favored choice for various applications, such as water and wastewater systems. High groundwater salinity refers to the increased presence of dissolved salts in the water. Although this can potentially cause corrosion in certain materials, ductile iron pipes are specifically engineered to withstand such conditions. These pipes are equipped with a protective lining, usually composed of cement mortar or polyurethane, which acts as a barrier between the pipe and its surroundings, including highly saline water. The lining serves to prevent any corrosive effects of the high groundwater salinity on the iron pipe, ensuring its long-lasting durability and reliability. Furthermore, ductile iron pipes possess a high tensile strength, enabling them to endure external loads and pressure, even in demanding environments. It is important to acknowledge that the suitability of ductile iron pipes for areas with high groundwater salinity can also be influenced by factors such as the specific levels of salinity, the presence of other corrosive agents, and the overall design and installation practices. Therefore, it is advisable to consult experts or engineers who are familiar with the local conditions in order to determine the most appropriate materials and precautions for specific installation projects.

- Q: Ductile iron pipe joint damage, water leakage, want to see the connection with other pipe fittings, how to operate?!

- The ink tube is really not good. Oh, have you tried blocking it with cement or plugging it with putty?Just pick up PE haha

- Q: What are the different pressure classes available for ductile iron pipes?

- There are several pressure classes available for ductile iron pipes, which are typically used for water and wastewater applications. The most common pressure classes for ductile iron pipes include Class 150, Class 200, Class 250, Class 300, and Class 350. These pressure classes indicate the maximum working pressure that the pipe can withstand in pounds per square inch (psi). Class 150 ductile iron pipes have a maximum working pressure of 150 psi, while Class 200 pipes can handle up to 200 psi. Class 250 pipes can withstand pressures up to 250 psi, and Class 300 pipes have a maximum working pressure of 300 psi. The highest pressure class, Class 350, can handle pressures up to 350 psi. The selection of the appropriate pressure class for a ductile iron pipe depends on various factors such as the system design, fluid characteristics, and operating conditions. It is important to consult the relevant standards and guidelines, such as the American Water Works Association (AWWA) standards, to determine the appropriate pressure class for a specific application. It is worth noting that these pressure classes refer to the working pressure of the pipe, which is the pressure the pipe is designed to safely contain during normal operation. The pipes are typically tested and certified to ensure they meet the required pressure class standards.

- Q: Are ductile iron pipes resistant to abrasion or wear?

- Yes, ductile iron pipes are highly resistant to abrasion or wear due to their inherent strength and durability.

- Q: Can the sealing ring of ductile iron pipe be reused?

- It is better not to have used things, easy aging, sealed, the best to use new

- Q: How many meters does the cast iron water supply pipe dn150,1 tons?

- Centrifugal ductile iron pipe water-cooled metal type centrifuge daira executed by.Dg100 mm following the closed mold mold jacket cooling, more than Dg150rnm with rain type cooling.

- Q: How do ductile iron pipes perform in high-traffic areas?

- Ductile iron pipes perform exceptionally well in high-traffic areas due to their inherent strength and durability. These pipes are manufactured using a unique composition that includes graphite nodules, which give them their characteristic ductility. This ductility allows the pipes to flex and withstand heavy loads and vibrations caused by traffic without cracking or breaking. In high-traffic areas, where the ground is subject to constant movement and heavy loads from vehicles, ductile iron pipes offer superior resistance to stress and impact. Their ability to absorb and distribute the pressure from traffic ensures that these pipes maintain their structural integrity over time. This is particularly important as any damage or failure in a pipe system can result in costly repairs and disruptions to the water supply. Furthermore, ductile iron pipes are highly resistant to corrosion, making them suitable for installation in high-traffic areas exposed to various environmental conditions. The pipes are typically lined with a protective layer, such as cement mortar or epoxy, which provides an additional barrier against external factors. This corrosion resistance ensures the longevity of the pipes, reducing the need for frequent maintenance or replacement. Additionally, ductile iron pipes have excellent flow characteristics, allowing for efficient water distribution even in areas with high traffic demands. Their smooth interior surface minimizes friction and pressure losses, ensuring a consistent and reliable water supply to meet the needs of the surrounding population. Overall, ductile iron pipes are a reliable and robust choice for high-traffic areas. Their strength, durability, corrosion resistance, and efficient flow characteristics make them well-suited for withstanding the demands and challenges posed by heavy traffic, ensuring the continuous supply of water without compromising the structural integrity of the pipe system.

- Q: How do ductile iron pipes handle ground settlement due to construction activities?

- Ductile iron pipes have the ability to handle ground settlement caused by construction activities due to their flexibility and strength. These pipes are designed to withstand external pressure and can accommodate minor ground movements without significant damage or failure. The ductility of the material allows the pipes to deform slightly, absorbing the ground settlement and preventing them from cracking or breaking. Additionally, the joints in ductile iron pipes are typically flexible, allowing for further movement and reducing the risk of leakage or structural issues. Overall, ductile iron pipes are well-suited for withstanding ground settlement and ensuring the integrity of the pipeline system during construction activities.

- Q: Can ductile iron pipes be used for underground water treatment systems?

- Indeed, underground water treatment systems can utilize ductile iron pipes. Renowned for their robustness and longevity, these pipes are well-suited for a range of uses, including underground water treatment systems. They possess exceptional resistance to corrosion, rendering them perfect for transporting water through even the harshest subterranean surroundings. Furthermore, ductile iron pipes boast a remarkable load-bearing capacity, enabling them to withstand the immense pressure and weight exerted by the soil above. Additionally, their versatility allows for simple installation and maintenance, making them a sensible option for underground water treatment systems.

- Q: Can ductile iron pipes be used for underground fire protection systems?

- Yes, ductile iron pipes can be used for underground fire protection systems. Ductile iron has excellent strength and durability, making it suitable for handling the high pressures and extreme conditions associated with fire protection systems. Additionally, it has good corrosion resistance, allowing the pipes to withstand exposure to moisture and other underground elements.

Send your message to us

Ductile Iron Pipe DN80 DN100 DN200 K8 K9 K7

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords