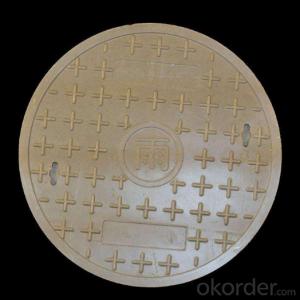

Ductile Iron Manhole Covers With EN124 Standard Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5.Packing

Steel or wood pallet, or as per customers' requirements'

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| D90 | D400 | 800*800 | 907*907 |

Advantages

Good compressive, water-proof, hot sale around the world,anti-corrosion, serviceable life (at least 30 years).

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products in China, Our prices are very favorable and competitive. The customers from all-over the world.

2.How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.How about your service?

We provide packaging service and after sale service as well.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- You oily sludge!Is not the general market on the soil?If it isPlease use two groups of chemicals to reinforce the soilOr suggest your company?Do the putty or paint film after doingThat's better

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- There are several casesThe first hole with a diameter of less than 4MM is generally not done, or as a hole location only for a period of less than 10MM.Second for the big hole, some of the reasons for the holding force, we must increase the slope, direct tapping is unlikely, so it still needs post-processingThird for products with high tightness requirements, some cores need to be made even if they are very small, so they can be tapped directlyFourth, some due to technical requirements, regardless of the size of each other's requirements must be made, there is no wayThe above methods are common, and they will encounter many small problems in actual production.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- What you say is the difference between rough drawing and processing drawingThere must be a difference between the rough drawings and the rough ones

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

Send your message to us

Ductile Iron Manhole Covers With EN124 Standard Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches