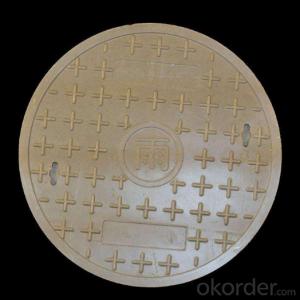

Ductile Iron Manhole Covers With EN124 Standard by Professional Manufacturers in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

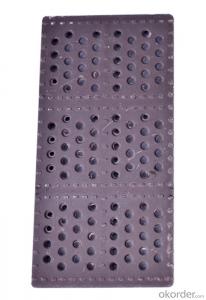

1) Type:round type and Square type,triangle

2) Process

c) Molding boards

d) Green sand with hand molding

3) Coating

a) Cold applied black bitumen

b) Without coating

c) Coating as per customers' requirement

4) Different accessories are available

5)Packing

Steel or wood pallet, or as per customers' requirements'

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) |

| D90 | D400 | 800*800 | 907*907 | 100 |

| D70 | D400 | 600*600 | 703*703 | 100 |

1.Applicable medium:gases,liquids,steam

2.Materail:ductile iron,Gray cast iron

Tested item standad

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4

Water-absorption<1.0

Surface treatment

Black bitumen coated and hot gavanized

Smooth surface and anti-theft

Advantages

Good compressive, water-proof, hot sale around the world,anti-corrosion, long service life (at least 30 years).

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container, and we will deliver your goods as soon as possible.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products in China, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3.Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- 2, causes(1) sand mold (core) strength is not high, when the box a little reason will fall off.(2) the strength of sand mould (core) is not high, it can not stand the erosion of molten steel.(3) box sand mould (core) crush.(4) high strength under high temperature, warpage, deformation and protuberance into the cast steel under the action of high temperature molten steel.(5) the floating sand in the air hole of the sand mold falls, especially when the floating sand falls in the casting, and the floating sand on the surface of the sand mold is easy to fall through the air vent.(6) when the box is closed, the surface of the mold cavity and the surface of the sand core are not cleaned, and the sand (core) surface has floating sand and so on.

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- It has something to do with the size of your work, and it has a lot to do with the blade you're using right now.

Send your message to us

Ductile Iron Manhole Covers With EN124 Standard by Professional Manufacturers in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches