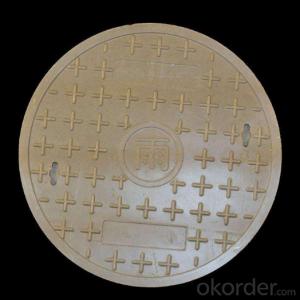

Ductile Iron Manhole Covers With EN124 Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Sample is available for free.

2. Free charge of design labels and cartons.

3. Professional technical support with free charge.

4.Packing

Steel or wood pallet, or as per customers' requirements'

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| D90 | D400 | 800*800 | 907*907 |

Materail:ductile iron,Gray cast iron

Tested item standad

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4

Water-absorption<1.0

Surface treatment

Black bitumen coated and hot gavanized

Smooth surface and anti-theft

Advantages

Good compressive, water-proof, hot sale around the world,anti-corrosion, serviceable life (at least 30 years).

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products in China, Our prices are very favorable and competitive. The customers from all-over the world.

2.How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.How about your service?

We provide packaging service and after sale service as well.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

Send your message to us

Ductile Iron Manhole Covers With EN124 Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches