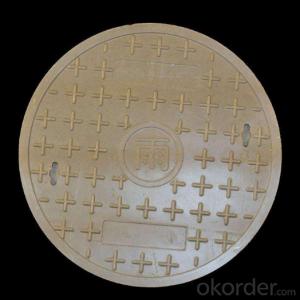

Ductile Iron Manhole Cover With EN124 Standard Made by Professional suppliers in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6.Packing: Steel or wood pallet, or as per customers' requirements'

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| D90 | D400 | 800*800 | 907*907 |

| D70 | D400 | 600*600 | 703*703 |

Advantages

Good compressive, water-proof, hot sale around the world,anti-corrosion, serviceable life (at least 30 years).

Anti-theft, anti-corruption.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

2. How about the shipment?

A. Small quantity you can choose by air

B. One container or more than one container you can choose FCL shipment by sea.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: What are the casting parts used to test shrinkage holes?

- 3 fluorescent magnetic powder, this method can also be found in part.

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Now resin sand, coated sand and other processes are also very good surface.

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Why should pig iron be used in casting?

- Cast iron is generally called pig iron, but casting is not merely iron casting.For example, injection molding, die casting, and so on, in fact, cast iron, cast steel, cast aluminum, plastic and so on, can be used in the form of casting processing molding

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- (3) to prevent generating white grey cast iron, in addition to taking measures from the process, must make the wall thickness is not too thin (some sources indicate that the corner wall thickness above 15mm, metal type casting must be in the corner, for Aluminum Alloy, magnesium alloy casting casting casting Create fillet should not be less than 3-4m, for casting round cast iron, copper alloy mould casting can see table 1.1-32 selection; (5) because of the metal and the core without let, for the convenience of the casting is taken out and the draw out type, slope casting casting should be suitably large than sand casting metal casting. General 30%-50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction and metal surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal castings the type should be given greater inclination, all kinds of metal type alloy casting casting casting.

Send your message to us

Ductile Iron Manhole Cover With EN124 Standard Made by Professional suppliers in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches