Ductile Iron Manhole Cover of Different Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1.Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

2. Designs

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

3. Process

c) Molding boards

d) Green sand with hand molding

4. Coating

a) Cold applied black bitumen

b) Without coating

c) Coating as per customers' requirements

Features:

· Higher quality /higher tensile

· Higher security /long life

· Possibilities of new locking systems

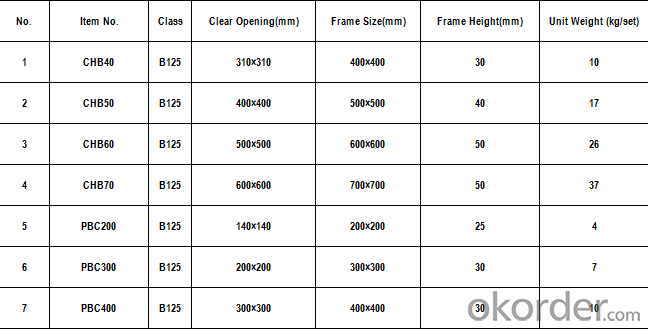

Specifications:

Pictures:

Packaging & Shipping:

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements.

B. Small quantity trial order is welcome.

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery.

E. Good after sales service.

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air.

B. Less than one container you can choose LCL shipment by sea.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing? In the casting industry is not called proofing, proofing is generally used in the printing industry, that is, according to the customer's drawings or samples, to do a first piece, to provide customers with the inspection process to meet their requirements;In the foundry industry, providing prototypes is sometimes difficult:1, customers if the provision of mold, it would be best, at this time, sample costs are very low, and almost the same as your regular products;2, the customer does not provide the mold, but in business relationships, your factory and not very sure must take this one, it requires your leadership decision-making, is free or low cost, or by a strict process offer (of course sample);3, not all of the casting process to provide samples are difficult, like lost foam can directly make a white NC prototype, and then assembled pouring, this is her unique advantages, first cost less than the opening process and so on;If you don't understand, you can continue to question me

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger,

Send your message to us

Ductile Iron Manhole Cover of Different Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches