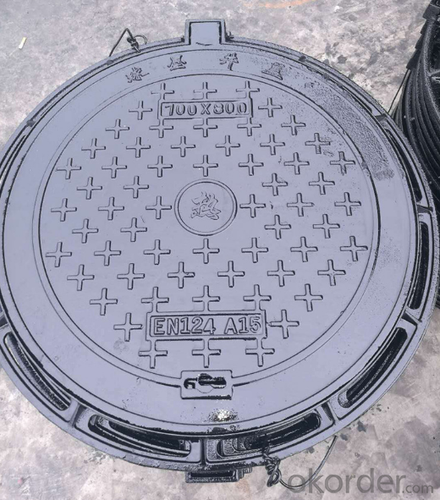

Ductile Casting Iron Manhole Cover with Square or Round Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5).we can produce as per customers' drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| CHC40 | C250 | 300×300 | 400×400 | 40 | 13 |

| CHC60 | C250 | 500×500 | 600×600 | 55 | 29 |

Advantages

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from scopeShanghai Zhejiang forest auto parts experts pointed out that the forging process can eliminate cast loose, metal welding holes, so an important part of high load working conditions, severe machinery, in addition to relatively simple shapes can be rolled plates, profiles or welded parts, the forging process. Because of its low cost and good economy, casting parts processing is widely applied and belongs to the basic process of modern machine building industry.

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

Send your message to us

Ductile Casting Iron Manhole Cover with Square or Round Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches