Ductile Iron Manhole Cover with Square and Round Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Product information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs .

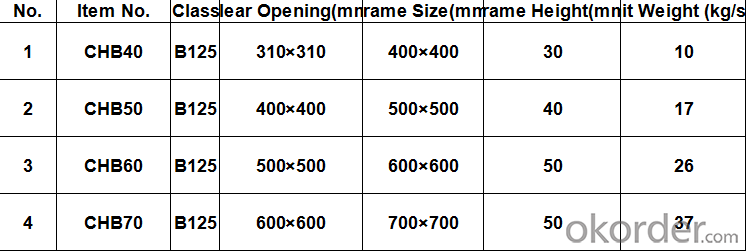

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

4) Process

c) Molding boards

d) Green sand with hand molding

5) Coating

a) Cold applied black bitumen

b) Without coating

c) Coating as per customers' requirement

6) Different accessories are available

7)Packing

Steel or wood pallet, or as per customers' requirements'

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Problem one,1, according to drawings, castings, material requirements and machine power, choose the right diameter of roughing tools, and can process this material blade type.2, according to the actual size of the casting blank, calculate the number and path of the knife, pay attention to small cutting depth, large feed, cutting width, to ensure that the tool diameter 80 - 90%, the amount of not full knife cutting, this tool and machine tool damage.Question two,If they can not change the casting blank allowance under the condition that the quantity large diameter cutter, such as milling cutter main angle 7560 degrees can give reasonable processing parameters, the same cutting depth should not be too large, because in the same machine power, tool diameter increases, cutting depth will need smaller.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

- Q: What's the cause of the choking of the casting?,

- 2. when casting mold exhaust condition is not good, in the casting material use consider whether and hinder its gas permeability; in the process to consider to release more pores, multi venting; core exhaust is particularly important.

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

Send your message to us

Ductile Iron Manhole Cover with Square and Round Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches