Ductile Cast Iron Manhole Cover B125 with Ranges of Colors

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3800 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

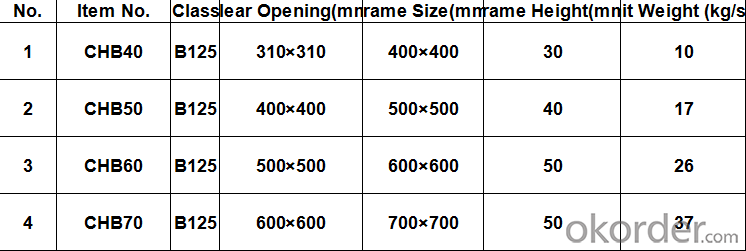

Specification

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Product Description:

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging and Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Pictures

FAQ:

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai ,Italy, South Africa or your local market are imported from China. So why not buy direct from China. The key point is to find a reliable supplier who is honest and professional to take care of the quality and delivery time.

3.Chinahas full range of Manhole covers which Follow En124 for your market, like A15,B125,C250,D400.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Ductile Cast Iron Manhole Cover B125 with Ranges of Colors

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3800 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords