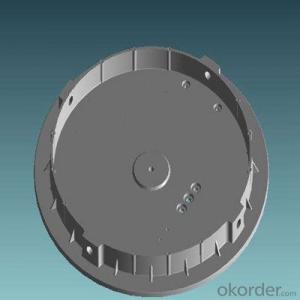

Ductile Iron Manhole Cover with Ranges of Colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron,

3) Type:round type and Square type,triangle

4) Sand casting,

5).we can produce as per customers'drawings

6)ISO9001:2000

Feature

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

Packing

Our company

Ductile Iron Manhole Cover and Grating

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group. CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

FAQ

1. Can I negotiate the Prices?

Yes, we may consider discounts for bulk orders.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3. How long will it take to execute my order?

For the stock items , we can arrange the shippment within 3-5 days after received your payment . For the customized items , we will indicate the delivery time in the quotation sheet .

4. Can you give warranty of your products?

Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with SYI 's quality or service. For the overseas orders,if there is quality problem , please kind to provide the pictures to show the problems by e-mail . We will provide the replacements to you at our cost according to actual conditions.

5. Can I visit you?

Sure, we have a showroom in our factory, China. If you are a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.

6. Why don't you state your prices on your website?

We are a business-to-business company and seldom sell to the terminal consumers. Considering our clients` interests and privacy, we actually do not state our prices on our website. The reason is that our client does not want their cost is shown to consumers. We hope that you can submit a target price form to us since we actually need to investigate our markets, which helps us to tune in to our client's need and provide them with more information of new products. It also helps us to verify whether or not an inquiry is from a bona fide business.

7. How can I know how my order is being done?

We will inspect and test all merchandise in case of damage and missing parts before shipping. The detailed inspection pictures of the order will be sent to you for your confirmation before delivery.

More questions, Please contact us now!

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Steel parts are not familiar. But after spraying, the powder should be divorced from the adhesive force is too low, try to provide the surface roughness of the casting

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to the grade of the parts, according to the relevant standards, the regular drawings will be noted in the technical requirements of the parts.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

- Q: What are the general technical requirements for casting parts?

- No matter what kind of material casting, there are the following major requirements:Material requirements. Mainly hardness, tensile strength, elongation, impact toughness.Two, dimensional accuracy and shape accuracy. Different castings have different requirements. Different sizes and geometric tolerances and different tolerances are adopted.Three, according to the use requirements, the casting of other defects, acceptance requirements. Such as holes, sand holes, shrinkage, slag, sand, crack.........Four. Requirements for defect repair.

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Ductile Iron Manhole Cover with Ranges of Colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches