DRL 120 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

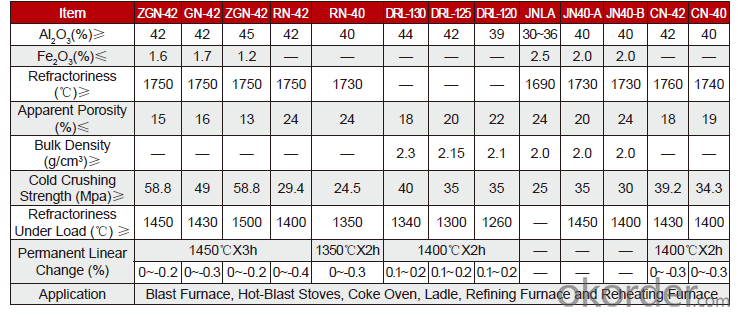

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: The matching ratio of masonrying refractory bricks cement

- When building refractory bricks, use matching chamotte, do not use cement

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: when to replace the worn refractory bricks in rotary?kiln?

- Wear out at least 23.

- Q: What is the problem about splintering when the refractory brick is fired?

- There are many bubbles inside the refractory brick, it is also possible that the brick itself is not up to the standard about volume density, then refractory brick fragmentates. There are many reasons, may be in the process of repression

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- When the production of sintered clay brick, brick baking in an oxidizing environment and a kiln, produce red brick; if the first brick in an oxidizing roasting, and then watering stuffy kiln, the kiln to form reducing atmosphere, makes the three brick red iron oxide is reduced to a high oxygen low iron and preparation so blue. The durability of brick brick than good.

- Q: How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- Dark red? Bright red? Orange red? 400,1100 or 1500 probably

- Q: is there any requirement for radioactive materials in refractory materials.

- they all do not cause radiological hazards to the environment, so no requirements! analyze rom the element , magnesia. Do not know if it is useful, but material used by refractory materials, firstly any chemical elements are radioactive, human beings can not close, then, such as silicon dioxide: If it is radioactive. analyze from use, such as bauxite, does not have the use value

- Q: Whether fireclay raw materials or clinker are used when masonrying general fireclay?brick? What is the difference between raw material and clinker?

- Of course is clinker, the raw material belongs to precast block, besides, clay and chamotte are mixed with glassy water and fine powder, fine powder belongs to raw materials.

- Q: What is the difference between the refractory bricks, hand-made bricks and the machine pressure bricks?

- Hand-made brick mainly produces brick that is not easy to produce molding Machine pressure brick adopts 100 tons of press machine to mold the density of hand-made brick is not enough, it's light; machine pressure bricks can only produce bricks that produce molding at a time, hand-made bricks mainly adopts hydraulic vibration molding machine

Send your message to us

DRL 120 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords