Fireclay Brick - CN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

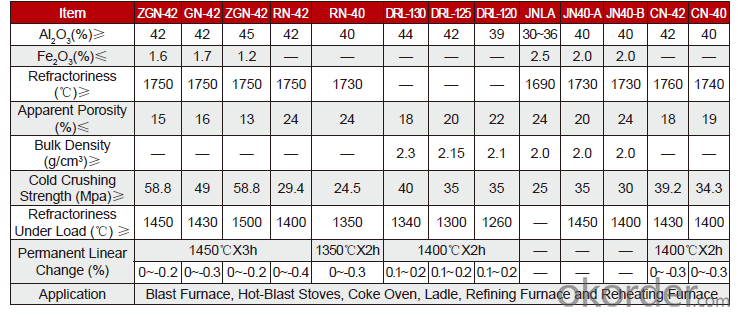

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How to built refractory bricks as fitting between square and circle ducts

- Build a big mushroom, and build the legs as square

- Q: High alumina refractory bricks (Universal arc) weight for hot metal ladle

- Climbing, C23B ladle generally use T3 ladle bottom brick, brick wall with C23 package, C231 Some permanent layers are built from high alumina bricks, and some are built from castable refractory, T82, T43. Specific size can be checked according to the type of brick

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: How many years are the service life of chimney lining refractory brick?

- Capacitance magnesite, seawater magnesite, should be the alkaline refractory brick, magnesia-alumina spinel can absorb hydrogen fluoride, generally are magnesia brick, magnesium iron ore, forsterite, dolomite, magnesium dolomite, magnesium silica sand, magnesia-chorme spinel and magnesia chrome sand: Magnesia mineral, magnesium calcium sand, magnesite, magnesium dolomite sand, dolomite, mainly is cordierite

- Q: What materials make of clay insulating fireclay brick?

- Clay insulation bricks are general according to the different origins of raw materials, not the same

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- Generally speaking, compared with the exterior burning brick, the internal combustion brick not only saves the clay and the waste material, but also has smaller volume density, lower thermal conductivity, and can increase the intensity by about 20%. Burnover light color, sound, low intensity; burned brick deep color, crisp sound, high strength, irregular size. These two kinds of bricks are unqualified products.

- Q: the amount of per square refractory brick of Various specifications and thickness of the refractory brick wall

- 9 grams-47. 7 grams- 47 calculate by your own according to the actual volume; cubic centimeter; 2.2 grams Clay brick 2: 1; 3, high alumina brick 3; cubic centimeter; standard density, cubic centimeter: 230mm * 114mm * 65mm, diatomite insulation brick 0, you can calculate the reference value

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q: Are clay bricks radioactive?

- Basically, any substance has radiation, because natural conditions contain a lot of radioactive particles, and even the body itself has reflective particles, such as carbon 14, but the dose is safe.

- Q: MU10 what are the non clay solid bricks?

- Mu10 is the strength grade of bricks, divided into grades MU7.5, 10, 15, 20, 25, 30 and so on. Non clay brick "non sintered clay bricks, such as sand brick, shale brick, cement brick, fly ash brick etc..

Send your message to us

Fireclay Brick - CN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords