Packaging Tape Texture Tissue Tape Double Sided Water Based Acrylic 80micron Black Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

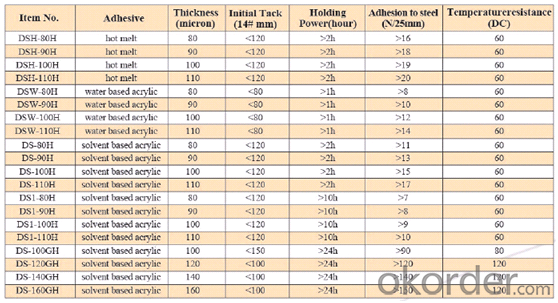

Typical Physical Reports of Double Sided Tissue Tape

Packaging Detail

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How much weight can packaging tape hold?

- The holding capacity of packaging tape varies based on multiple factors, including the tape's type, quality, the surface it adheres to, and the method of securing it. Typically, regular packaging tape can support weights between 20-30 pounds (9-14 kilograms). Nevertheless, heavy-duty or reinforced packaging tapes have the ability to endure significantly higher weights, ranging from 40-70 pounds (18-32 kilograms) or even more. To maximize the tape's holding capacity, it is crucial to apply it accurately, ensuring adequate coverage and pressure.

- Q: How do I prevent packaging tape from curling up?

- Here are some suggestions for preventing packaging tape from curling: 1. Opt for a tape dispenser: Employing a tape dispenser not only maintains the tape's straightness but also prevents it from curling. Moreover, it facilitates cutting the tape to the desired length. 2. Apply the tape evenly: While applying the tape, ensure to pull it tightly and evenly across the surface. Avoid any creases or air bubbles as they can cause the tape to curl. 3. Ensure surface cleanliness: Prior to applying the tape, guarantee that the surface is clean, devoid of dust, dirt, or moisture. These elements can interfere with the tape's adhesive properties and lead to curling. 4. Store the tape correctly: Proper storage of packaging tape is crucial for preventing curling. Keep it in a cool, dry place, away from direct sunlight. Drastic temperature fluctuations can impact the adhesive properties of the tape and result in curling. 5. Select high-quality tape: Invest in top-notch packaging tape specifically designed for long-term adhesion. Cheaper tapes often possess lower quality adhesives that are more prone to curling. 6. Utilize a heat source: If you encounter curling issues with the tape, you can attempt using a heat source, such as a hairdryer on a low setting. Gently warm the tape while applying it to activate the adhesive and minimize curling. By adhering to these suggestions, you can successfully prevent packaging tape from curling and achieve a secure and professional packaging appearance.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes as it provides a strong adhesive bond and can effectively secure the contents inside. However, for heavy-duty or industrial applications, it is recommended to use specialized tapes designed specifically for sealing metal surfaces.

- Q: Is packaging tape compatible with automatic packaging machines?

- Yes, packaging tape is compatible with automatic packaging machines. Automatic packaging machines are designed to work with a variety of packaging materials, including packaging tape. They are equipped with mechanisms to efficiently dispense and apply packaging tape to seal packages.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. Packaging tape is designed to have strong adhesive properties, making it ideal for securing and sealing various items, including sports equipment. It can help keep equipment and gear securely fastened, preventing them from coming apart or getting damaged during transportation or storage. However, it's important to consider the specific needs and requirements of the sports equipment or gear being sealed, as some items may require more specialized tapes or sealing methods for optimal protection.

- Q: What's the ingredient of 610#3m tape?

- Specifications: 25.4 mm * 65.8mWidely used in silk screen, printing and other processes. Prosecution of its ink adhesion, is a standard test means, such as: printed circuit boardPlastic products, silk screen, jet printingApplications: electronic products, silk screen, jet printingTest adhesive features: sticky stability, strong adhesion, international standard test tape

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Yes, packaging tape can be used for sealing plastic or poly bags. Packaging tape is specifically designed to provide a strong and secure seal on various surfaces, including plastic and poly bags. It has an adhesive backing that adheres well to the plastic material, ensuring that the bag remains tightly sealed. However, it is important to note that there are different types of packaging tape available, so it is recommended to choose a tape specifically designed for sealing plastic or poly bags to ensure optimal performance and long-lasting seal.

- Q: What are the benefits of using tamper-evident packaging tape?

- Tamper-evident packaging tape offers several benefits, including enhanced security and protection of goods during transit. It provides a clear indication if the package has been tampered with, ensuring the integrity of the contents. This not only helps prevent theft and unauthorized access but also increases customer confidence in the product. Additionally, tamper-evident tape acts as a deterrent, discouraging potential tampering or pilferage. Overall, it offers peace of mind, improved product safety, and a reliable way to maintain the authenticity of packaged items.

- Q: Can packaging tape be used for sealing foam?

- Sealing foam can be achieved by using packaging tape. While packaging tape is commonly used for sealing boxes and packages, it can also be effectively used to seal foam. To create a tight seal, it is important to make sure that the tape is securely adhered to the foam surface by applying pressure after it has been applied. It is advisable to use a tape specifically designed for sealing foam, as these tapes usually have stronger adhesive properties and are more resistant to temperature changes and moisture. In conclusion, packaging tape can be a convenient and effective choice for sealing foam.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to perform well in high-pressure conditions. It is typically made from strong and durable materials such as polypropylene or polyester, which can withstand pressure, tension, and stress. These tapes have excellent adhesive properties that enable them to bond securely with various surfaces, even under high pressure. Additionally, packaging tapes are often equipped with features like reinforced fibers or water-activated adhesives, which further enhance their performance in demanding conditions. Overall, packaging tape is reliable and effective for sealing and securing packages, even in high-pressure environments.

Send your message to us

Packaging Tape Texture Tissue Tape Double Sided Water Based Acrylic 80micron Black Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords