DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000TONS m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

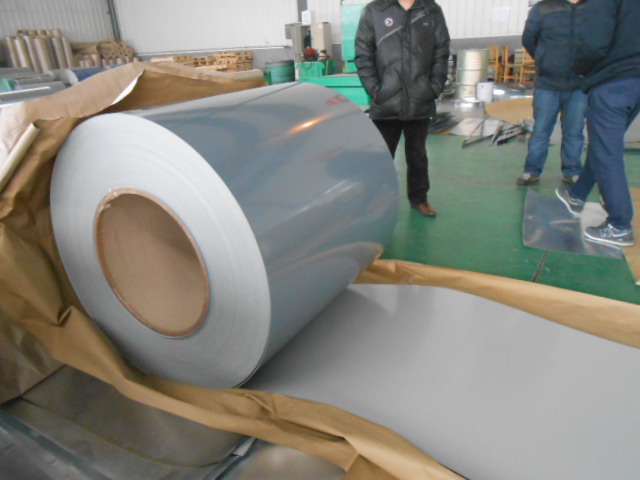

DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

THICKNESS:0.95mm(-/+0.02mm)

WIDTH:1250mm(0/+5mm)

ZINC COATING:60g/m2 (-/+10g/m2)

COLOR: ACCORDING TO COLOR SAMPLE.

TOP COATING:5+13 MICRON, BACK COATING:5+13 MICRON; (-/+2MICON)

COIL WEIGHT:3-5 ton

STANDARD:JIS G 3312

STEEL GRADE:CGCC

COIL ID:508mm

- Q: I understand that damascus sword steel was made by folding the strip of steele double , reheating, hammering, folding again and so forth hundreds of times. Was this the same or very nearly the same techmique the japs used making the sword blades the samari swords?(forgive the misspelling)

- Damascus: A folding technique where the steel is folded over itself many (generally up to sixteen) times, leading to hundreds or even thousands of layers (one fold = 2 layers, two folds = 4 layers, three folds = 8 layers, 16, 32, 64, 128, 256, 512, 1024, 2048, 4096, etc.). More folds than sixteen are pointless, as the layers would become thinner than one molecule - which is impossible. This method was developed to removed impurities from the steel (it also removes carbon, which is bad, but can be compensated for to some degree), but modern steel is so pure that Damascus folding is no longer needed. It is now used for aesthetic reasons; Damascus steel looks really good; you can see the layers in the blade. San Mai: Translates to three layers. Layers of softer, lower carbon steel (or iron) is forge welded to layers of harder, higher carbon steel. The lower carbon steel forms the core (and sometimes the sides and/or back), and the higher carbon steel forms the edge. The hard edge will hold its sharpness, the softer core provides shock absorption; making the sword harder to break. Unlike Damascus, San Mai is still very practical. San Mai folds should be invisible; if you can see a San Mai fold the forging was flawed and the blade should be discarded - you'll have to trust your seller that the blade is San Mai - you can't tell by looking. San Mai can be revealed by etching the blade with acid, such as lemon juice, but I don't recommend trying this unless you know what you're doing; you can permanently stain the blade. San Mai swords are more durable (and more expensive) than simple blades. They are more durable (and usually less expensive) than Damascus blades. A blade can be either San Mai or Damascus, or it can be both; Damascus steel which is then San Mai folded. Very cool, looks good and lasts long.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- A steel pick + acoustic on nylon strings = not so good A steel pick + acoustic on steel strings = this might work A steel pick on electric guitar = this might work too I don't think you would trash the guitars, and you probably wouldn't have to worry about being electrocuted...lol... A plastic pick would be so much better. Do they even make steel picks ?

- Q: How are steel coils protected against bending and deformation?

- Various measures are implemented to safeguard steel coils from bending and deformation. One prevalent approach entails employing protective packaging materials, such as wooden crates or metal skids. These materials provide stability and support, effectively preventing any bending or deformation during transportation or storage. Additionally, steel coils are frequently tightly secured using steel or plastic bands. This measure serves to maintain their shape and prevent any shifting or movement. These bands are strategically positioned at regular intervals along the length and width of the coils, guaranteeing even pressure distribution and minimizing the risk of bending or deformation. Furthermore, steel coils can be further shielded by placing them on a flat and level surface during storage or transportation. This practice ensures the even distribution of weight, thus reducing the likelihood of bending or deformation due to uneven pressure. In certain instances, steel coils may also be coated with anti-corrosion agents. This protective coating shields against moisture and rust, which can weaken the structural integrity of the coils and lead to bending or deformation over time. In conclusion, the combination of appropriate packaging, secure fastening, and careful handling is paramount in safeguarding steel coils against bending and deformation. This comprehensive approach ensures the maintenance of their structural integrity and quality.

- Q: Can steel coils be coated with RFID technology?

- Yes, steel coils can be coated with RFID technology. This technology allows for tracking and identification of the steel coils, improving supply chain management and providing real-time information on their location and status.

- Q: What are the surface treatments for steel coils?

- There are several surface treatments available for steel coils, each serving a specific purpose and offering unique benefits. Some common surface treatments for steel coils include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, resulting in a protective layer of zinc coating on the surface. Galvanizing provides excellent corrosion resistance, making the steel coil suitable for outdoor applications in harsh environments. 2. Electro-galvanizing: This method uses an electrolytic process to deposit a thin layer of zinc onto the steel coil's surface. Electro-galvanizing provides good corrosion resistance, but the coating is generally thinner compared to hot-dip galvanizing. 3. Pre-painting or pre-coating: Steel coils can be coated with paints or other coatings before being formed into final products. This surface treatment enhances the coil's aesthetic appeal while offering protection against corrosion, weathering, and other environmental factors. 4. Pickling and oiling: This surface treatment involves removing oxides and scale from the steel coil's surface by immersing it in an acid solution. After pickling, the coil is typically coated with oil to prevent rust formation during storage and transportation. 5. Phosphating: Phosphating is a chemical conversion coating process that forms a layer of phosphate on the steel coil's surface. This treatment improves the adhesion of subsequent coatings, such as paints or primers, while also providing some corrosion resistance. 6. Organic coatings: Steel coils can be coated with various organic materials, such as epoxy, polyester, or polyurethane, to enhance their corrosion resistance and aesthetic appearance. These coatings offer a wide range of colors, textures, and finishes, making them suitable for diverse applications. It is worth noting that the choice of surface treatment for steel coils depends on the intended application, environmental conditions, and desired appearance. Manufacturers and end-users must carefully consider these factors to select the most appropriate surface treatment for their specific needs.

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- As okorder /..

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary strength and durability required for containment and storage of various substances. These coils are rolled into cylindrical shapes and welded together to form the tank's body, ensuring a tight and secure structure. Additionally, the steel coils can be coated or treated to provide corrosion resistance, further enhancing the tank's longevity and suitability for storing liquids or gases.

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials.

Send your message to us

DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000TONS m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords