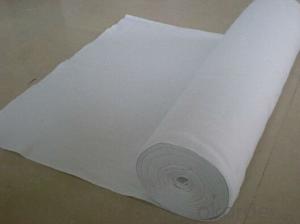

Delta Geotextile PP/PET Geotextile Fabric for Filtration and Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1,Specification of PP/PET Nonwoven Geotextile Fabric for Construction

1)Area Weight: 100g/m2-1500g/m2

2) Width: Within 6 m (1m-6m)

3) Length: 50m-100m/roll (as per request)

4) Material: Polypropylene or polyester

2,Specialities of PP/PET Nonwoven Geotextile Fabric for Construction:

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3,Package of PP/PET Nonwoven Geotextile Fabric for Construction:

Each roll is wrapped with plastic film.

4,Application of PP/PET Nonwoven Geotextile Fabric for Construction:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles can provide reinforcement and stabilization to slopes and embankments, helping to prevent soil erosion and rockfall. They can be used as a barrier between the rockfall source and the protected area, absorbing or redirecting the energy of falling rocks. Additionally, geotextiles can enhance the effectiveness of other rockfall protection measures, such as rockfall nets or fences, by providing additional support and filtration.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles provide stability, erosion control, and reinforcement to the mattress system, making it an effective solution for soil stabilization and erosion prevention. They enhance the overall performance and durability of the geocell mattress system.

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to form a permeable fabric with specific properties suitable for various civil engineering applications.

- Q: What are the potential drawbacks of using geotextiles?

- One potential drawback of using geotextiles is that they can be expensive to install and require skilled labor for proper installation. Additionally, geotextiles may deteriorate over time due to exposure to UV rays and environmental factors, leading to reduced effectiveness and potential replacement costs. Furthermore, if not properly designed and installed, geotextiles may trap water and cause drainage issues. Lastly, geotextiles are not suitable for all soil types and may not provide the desired level of soil stabilization or erosion control in certain situations.

- Q: How do geotextiles help in preventing clogging of drainage systems?

- Geotextiles help prevent clogging of drainage systems by acting as a filter, allowing water to pass through while preventing the entry of fine particles and debris that could potentially clog the system.

- Q: What are the different geotextile permeability testing methods?

- There are several different geotextile permeability testing methods, including the constant head method, falling head method, and gradient ratio method.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application and requirements. Some common techniques include trenching, anchoring, and overlaying. Trenching involves excavating a trench and placing the geotextile in the desired location, then backfilling the trench with soil or aggregate. Anchoring involves securing the geotextile to the ground using stakes or anchors, providing stability and preventing movement. Overlaying involves placing the geotextile on top of an existing surface, such as a road or landfill, to provide reinforcement and separation. The choice of installation technique depends on factors such as soil conditions, project specifications, and desired results.

- Q: It is good to cover the geotextile

- What are you breeding? Tarpaulin can be waterproof and waterproof, do not know if you have not seen geotextiles, geotextiles and silk cotton coat inside the like, light, there is a certain role in insulation, but not waterproof. Hope to help you

- Q: Filter geotextile performance ~ main function ~

- Filter geotextile performance ~ main function ~

Send your message to us

Delta Geotextile PP/PET Geotextile Fabric for Filtration and Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords