DEDB Replacement Of DOP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DEDB

Performance and Characteristics:

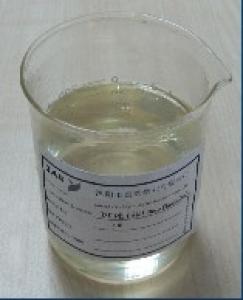

This product can replace Dactyl phthalate, deputy.A light color, plasticized, high efficiency, good compatibility, low volatility, low leakage,high thermal stability index, cold water extract, UV resistant, Not Easily oxidized and volatile, excellent electrical performance characteristics, is the plasticizer industry Lowest Prices of new plasticizer, Reducing the cost of more than 30% of plastic products.

Specifications:

Items | Specification |

Appearance | white odorless transparent liquid |

Color (Pt-Co) : | 45-50 |

Ester content:% ≥ | 98 |

Acidity: (in acid dollars)% ≤ | 0.01 |

Flash point (open cup) °C | 180-190 |

Heating loss (125 °C,) | 70min |

Application:

Used in PVC plastic granules, non-filled rolling film, artificial leather, cable, plates, sheets, soft and hard pipe,sole material, rubber products, foam material, film, paint, rubber, gl ass, printing ink, paste plasticized vinyl acetate emulsion adhesives.

Packaging: IBM, net weight: 1000 kg.

- Q: How many kinds of raw materials are produced by wrapping plastic film?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.Commonly used to bundle packaging is LLDPE stretch wrap film, applicable to a variety of logistics packaging, packaging industry bundled! I can see it in Ming Bao. Yes, please!

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- PS does not have no foaming agent. It is divided into GPPS (ordinary type) and HIPS (impact type). It is used for injection molding, extrusion, television, telephone shell, cup and so on.The main ingredients are polystyrene.

- Q: What kind of material is the plastic bag commonly used in supermarkets now?

- Another is PP or OPP, which contains bread and crackers. The material is smooth and very transparent, but the tightness is not very good and there is no tension.

- Q: What can recycled plastics do?

- Can replace some wooden products; can be used to make all kinds of plastic bags, barrels, pots, toys and other plastic products, living utensils. Recycled plastic granulator, plastic prospects, turn products (plastic particles) a wide, plastic enterprises demand, a medium-sized agricultural film factory, in need of more than 1000 tons of polyethylene particles, a medium-sized shoe factory in need of more than 2000 tons of PVC particles, smaller private enterprises, with particles in years more than 500 tons, so the plastic particles in a large gap, can not meet the demand, so the plastic manufacturers, sales of excellent, excellent benefits.

- Q: What are the raw materials for making plastics?

- Polymer: any of the pure or polymeric materials produced by the polymerization process, whether natural or synthetic resins, are polymers, polymers, or polymers

- Q: What is the material of plastic flat screen?

- Widely used in aquaculture, poultry farming, sericulture, civil construction, aquaculture, garden care, keep the field of railway and highway subgrade reinforcement, etc., can also be used for mattress, sofa cushion, car cushion, which is characterized by low cost, long service life.Material: high density low pressure polyethylene (PE), polypropylene (PP), ABS plastic particles.Colors: black, white, orchid, green, yellow, red and so on.

- Q: What plastic materials need to be dried for injection molding products?.. How much is the temperature?

- Plastic particles should be drying, remove moisture, in order to achieve this goal, generally should be drying temperature control at more than 100 degrees, but should be less than plastic (plastic varieties related) softening temperature.

- Q: That kind of plastic bottle blows well

- PETA hard, tough, high strength, bright surface with transparent and multi colored sheets. The disadvantage is PET high frequency synthesis is difficult, the price is a bit more expensive than PVC, this material is often high-grade products and environmental requirements of the user to replace the PVC PET material generally used to make packaging for food, beverage, pharmaceutical plastic bottles.

- Q: What kinds of plastic properties can be divided into thermal properties?

- A. thermoplastic(a) polyvinyl chloride (PVC)Is the most widely used plastic varieties. Polyvinyl chloride resin is made from poly (vinyl chloride) monomer. According to the amount of plasticizer, it is divided into hard PVC and soft PVC. The former adds 30~70 phr of plasticizer <5 in 100 heavy resins, and the latter adds plasticizers.Physical properties: the relative density of hard PVC is 1.35 to 1.60, which is 1 / 5 of carbon steel; the relative density of soft PVC is 1.2 ~ 1.4.The water absorption rate of hard PVC is very low. The water absorption rate in long-term immersion in water is <0.5%; the soaking water is 24h, and the water absorption is 0.05%. The permeability of PVC is very low.The glass state temperature of PVC is 80~85 DEG C, the viscosity is 180 DEG C, the decomposition temperature is 240~260 DEG C (including stabilizer), and the brittleness temperature is -50 ~ -60 DEG C.The recommended temperature range of hard PVC is, in principle, maintained in terms of brittleness and glass temperature. If it is used above 50 degrees, necessary measures should be taken.The pure PVC, without stabilizers, begins to decompose at 150 C, releases hydrogen chloride, and further accelerates its decomposition. It decomposes faster than 180 DEG C. The polyvinyl chloride with the stabilizer decomposes the temperature to 240~260 degrees centigrade, but breaks down hydrogen chloride if used for 220 years. The material changes from dark grey to yellow brown, or even black. Therefore, in welding, we should try to avoid this phenomenon, the linear expansion coefficient of hard polyvinyl chloride is (5~6) X10-5 / DEG, 5-6 times larger than carbon steel. Therefore, when installing polyvinyl chloride pipes, expansion joints or bracing shall be installed to prevent deformation. When polyvinyl chloride is used as lining or bonding with other materials, the peeling phenomenon may be considered when heated.

- Q: What are the properties of plastic material PS? What are the advantages and disadvantages?

- The parameters of PS plastic (polystyrene) English Name: Polystyrene weight: 1.05 g / cm3 molding shrinkage rate: temperature: 170-250 degrees 0.6-0.8% molding material properties of electrical insulation (especially high-frequency insulation) excellent, colorless and transparent, light transmittance after organic glass, color of water resistance, good chemical stability, strength, but brittle that is easy to produce stress cracking, no resistance to benzene. Gasoline and other organic solvents. Suitable for production of transparent insulation. Trim and chemical equipment. Optical instrument parts forming performance.

Send your message to us

DEDB Replacement Of DOP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords