Manufacturer of DEDB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

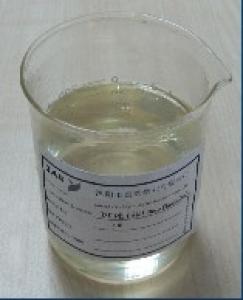

DEDB

Performance and Characteristics:

This product can replace Dactyl phthalate, deputy.A light color, plasticized, high efficiency, good compatibility, low volatility, low leakage,high thermal stability index, cold water extract, UV resistant, Not Easily oxidized and volatile, excellent electrical performance characteristics, is the plasticizer industry Lowest Prices of new plasticizer, Reducing the cost of more than 30% of plastic products.

Specifications:

Items | Specification |

Appearance | white odorless transparent liquid |

Color (Pt-Co) : | 45-50 |

Ester content:% ≥ | 98 |

Acidity: (in acid dollars)% ≤ | 0.01 |

Flash point (open cup) °C | 180-190 |

Heating loss (125 °C,) | 70min |

Application:

Used in PVC plastic granules, non-filled rolling film, artificial leather, cable, plates, sheets, soft and hard pipe,sole material, rubber products, foam material, film, paint, rubber, gl ass, printing ink, paste plasticized vinyl acetate emulsion adhesives.

Packaging: IBM, net weight: 1000 kg.

- Q: I'd like to know what PP plastic material is PP plastic raw materials cleaning can not use ultrasonic cleaning machine to wash it?

- PP plastic raw material is a thermoplastic resin. Its density is small, strength, stiffness, hardness, heat resistance are better than low-pressure polyethylene, can be used in about 100 degrees. With good electrical properties and high frequency insulation, free of moisture, but brittle at low temperatures, wear and aging, suitable for making general mechanical parts, corrosion resistant parts and insulation parts.

- Q: What are the common raw materials used in plastic bottles? What are the main features?

- PP bottles are non-toxic, transparent, and have certain heat resistance and impact resistance. They are generally loaded with fruit juice and shampoo. They can be hot filled (very important for fruit juice drinks). They can not be sterilized by pressure cookers, and their transparency is poor.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- Plastic tableware with melamine resin powder heat pressing, also known as melamine tableware melamine tableware.PP plastic is polypropylene, non-toxic, can make pots, buckets and other kitchen utensils.

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Engineering plastics generally have many properties that are not common in plastics. They are often used in construction machinery to replace certain metals.Plastic is resin and filler, so it is usually granular. Raw materials too. Only a few powdery.

- Q: What are the plastic raw materials?

- Plastic raw material is a kind of polymer (polymer), also known as macromolecule or macromolecule, also is commonly known as plastic or resin. The so-called plastic raw material, in fact, it is a kind of [synthetic resin], the shape of the natural resin [pine resin] similar, but because of the chemical strength of the synthesis, and is called plastic.

- Q: How to make plastic raw materials?

- oil refiningPetroleum crackingCracking is the process of breaking down hydrocarbons with relatively large molecular weight and high boiling point under certain conditions, which are relatively small molecular weight and low boiling point hydrocarbons.Cracking under catalysis, also known as catalytic cracking.

- Q: What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- Starch plastics containing starch in more than 90%, add other components also can be completely degraded, there are Japan Sumitomo Business Corporation, American Wamer-Lamber company, Italy Ferrizz company claims of success starchier in 90% to 100% of full starch plastics, in (January ~ 1) completely biodegradable without leaving any trace, no pollution, can be used in the manufacture of various containers, bottles, films and garbage bags etc. all starch plastics production principle is that the starch molecular allostent anddisorderly change formed with thermoplastic starch resin, also known as the thermoplastic starch plastics. The molding process can be used in traditional plastic processing equipment. With starch as the potential advantages of development of bio degradable plastics raw materials: starch has biodegradability completely in various environments; plastic in the degradation of starch molecules or after ashing, the formation of two oxygen Carbon gas, without soil or air poison; take appropriate technology to make starch thermoplastic after mechanical properties can reach for manufacturing plastic material; starch is a renewable resource, inexhaustible, pioneering starch utilization is conducive to rural economic development. That is, starch plastics production in China of vast the majority of starch filled plastics, is added in a certain proportion of polymer materials in non biodegradable starch, resulting in the collapse of material physical property through biodegradation of starch, prompted a large number of end groups that exposed to oxidative degradation, but the rest of the "collapse" after the PE, PVC and so on are not always possible degradation the residue in soil, of course, days and months multiplying will cause pollution, so the foreign ownership for such products will be eliminated.

- Q: ABS plastic storage conditions

- If it is ABS raw materials, storage: rainproof, moisture-proof, anti lightPacking is best provided with a PE inner bag for moisture proofThere is no place to pay more attention.

- Q: How do plastic materials come from?

- Plastic materials: is made of macromolecule resin (polymer) as the main ingredients penetrate various auxiliary materials or additives, in particular temperature, has the plasticity and fluidity under pressure, can be molded into shape and maintain the same shape of material under certain conditions.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

Send your message to us

Manufacturer of DEDB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches