Decorative Aluminum Coil for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Coils Used for Producing ACP

Plain aluminium coils used for producing ACP are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

They are widely used as base coils to produce ACP after being coated. Normal specification is 3003, H16, etc.

2.Main Features of Plain Aluminium Coils Used for Producing ACP

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

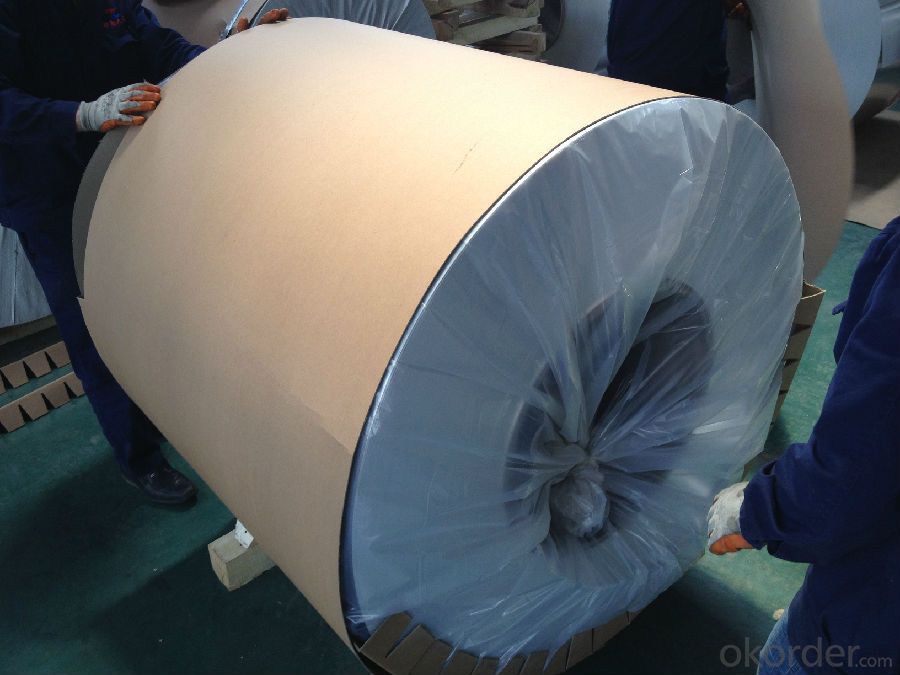

3. Plain Aluminium Coils Used for Producing ACP Images

4.Specification of Plain Aluminium Coils Used for Producing ACP

Alloy: AA3003, AA3105, etc

Temper: H16, H26, etc

Thickness: 0.3-1mm

Width:1000mm- 1500mm

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5.FAQ of Plain Aluminium Coils Used for Producing ACP

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Aluminum extrusions are bars made with hollow cavities that allow each to be joined easily, using special connectors. The primary difficulty when painting aluminum extrusions centers on the fact that they are nonporous and durable. Each of these traits creates a complication of its own.

- Your question supposes that you need to Paint the Aluminum Extrusion. The more common thing to do is to Anodize the extrusion. This process coats all surfaces with a hard durable coating. There are several colors available. Actually It's common to use Urethane's to paint Aluminum and the primer isn't simply made for metal, but is specifically for Aluminum. A lot of Airplanes are coated every day in this manner. Methods for coating the insides of tubing have been used for a very long time. You basically fill the tube with primer or coating then drain the excess out (dip method) and difficult shapes can be powder coated or electro static coated. Extrusions can be roller coated after cleaning, vinyls work very well with out priming. Think Toothpaste tubes.

- Q: What are the typical applications of aluminum coils in the automotive industry?

- Aluminum coils are widely used in the automotive industry for various applications due to their advantageous properties. One typical application is in the manufacturing of automotive heat exchangers, such as radiators and condensers. The high thermal conductivity of aluminum allows for efficient heat transfer, enhancing the cooling efficiency of the vehicle's engine and air conditioning system. Another common use of aluminum coils in the automotive industry is for making lightweight body panels and structural components. Aluminum is known for its low density, which helps reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces emissions. Additionally, aluminum's high strength-to-weight ratio makes it ideal for impact-absorbing structures, enhancing the safety of the vehicle. Aluminum coils are also utilized in the production of electrical wiring systems and connectors in automobiles. Aluminum's excellent electrical conductivity enables the efficient transmission of electrical signals throughout the vehicle. Furthermore, its corrosion resistance properties make it suitable for use in various weather conditions. Moreover, aluminum coils find application in the production of suspension systems, such as control arms and knuckles. The stiffness and durability of aluminum help enhance the vehicle's handling and responsiveness, resulting in improved driving dynamics. In summary, the typical applications of aluminum coils in the automotive industry include heat exchangers, lightweight body panels, electrical wiring systems, and suspension components. These applications capitalize on aluminum's advantageous properties, such as high thermal conductivity, low density, excellent electrical conductivity, and corrosion resistance.

- Q: What are the different protective coatings available for aluminum coils?

- Aluminum coils can be protected by various types of coatings. Some popular options include: 1. Polyester Coating: This coating is versatile and offers excellent resistance to weather and color fading. It is commonly used in outdoor settings where the coils may face harsh weather conditions. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings are highly durable and resistant to fading, chalking, and chemicals. They are often used in architectural applications that require a long-lasting and high-performance finish. 3. Epoxy Coating: Epoxy coatings provide strong adhesion and corrosion resistance. They are frequently utilized in industrial settings, such as the production of appliances or automotive parts. 4. Acrylic Coating: Acrylic coatings offer good weather resistance and protection against UV rays. They are commonly used indoors or in areas with mild outdoor exposure. 5. Polyurethane Coating: Polyurethane coatings are known for their high impact resistance and flexibility. They are often chosen for applications where the coils may undergo physical stress or deformation. 6. Ceramic Coating: Ceramic coatings provide exceptional heat resistance and thermal stability. They are commonly used in automotive applications or areas with high-temperature exposure. In conclusion, the selection of a protective coating for aluminum coils depends on specific requirements, such as weather resistance, durability, or chemical resistance. It is crucial to consider environmental conditions and performance expectations when choosing the appropriate coating.

- Q: Can aluminum coils be used in the production of consumer electronics?

- Yes, aluminum coils can be used in the production of consumer electronics. Aluminum is a lightweight and versatile metal that offers several advantages in the manufacturing of consumer electronic devices. It has excellent thermal conductivity, which makes it ideal for heat dissipation in electronic components such as motors, transformers, and power supplies. Aluminum coils are commonly used in the production of electronic devices such as smartphones, laptops, and tablets. They are often employed in the construction of the device's housing or casing, providing a lightweight and durable solution. Aluminum is also non-magnetic, which makes it suitable for electronic devices that require minimal interference with magnetic fields. Additionally, aluminum coils offer good electrical conductivity, making them useful in applications that require efficient transmission of electrical signals. They are often employed in the production of antennas, connectors, and other electronic components that require high conductivity. Moreover, aluminum is a highly recyclable material, which aligns with the growing demand for sustainable manufacturing practices. The use of aluminum coils in consumer electronics not only provides functional benefits but also contributes to a greener and more environmentally friendly production process. In summary, aluminum coils can indeed be used in the production of consumer electronics due to their excellent thermal conductivity, lightweight and durable properties, good electrical conductivity, and recyclability.

- Q: What are the different sizes available for aluminum coils?

- Aluminum coils are available in various sizes to meet the diverse needs of different industries and applications. The sizes of aluminum coils can vary depending on factors such as the intended use, manufacturing process, and customer requirements. Generally, aluminum coils are available in a range of thicknesses, typically ranging from 0.2mm to 8mm. The width of aluminum coils can vary from as narrow as a few inches to more than 60 inches. The length of aluminum coils can be customized, but standard lengths are often around 1000mm to 6000mm. The specific sizes available for aluminum coils may also depend on the manufacturing capabilities of the supplier or manufacturer. Some suppliers may offer a wide variety of sizes to cater to different customer demands, while others may have a more limited range of sizes. It is important to note that the availability of specific sizes may also be subject to minimum order quantities or lead times. Therefore, it is advisable to consult with the supplier or manufacturer to inquire about the specific sizes available and any limitations or requirements that may apply. Overall, the different sizes available for aluminum coils provide flexibility for customers to choose the most suitable dimensions for their specific applications and requirements.

- Q: Are there any certifications or standards for aluminum coils?

- Yes, there are various certifications and standards for aluminum coils. Some notable ones include the ASTM International standards, such as ASTM B209 for aluminum and aluminum-alloy sheet and plate, and ASTM B221 for aluminum-alloy extruded bars, rods, wire, profiles, and tubes. Additionally, the Aluminum Association provides industry guidelines and certifications, such as the Aluminum Association Registration for Aluminum Coil Production Facilities. These certifications and standards ensure that aluminum coils meet specific quality, performance, and safety requirements.

- Q: Can aluminum coils be used in heat sinks?

- Indeed, heat sinks can employ aluminum coils. Aluminum, renowned for its remarkable thermal conductivity, stands as a favored option for heat sinks. The prime purpose of these sinks is to avert overheating by expelling heat from electronic components and other devices. By incorporating aluminum coils into heat sinks, one can augment the surface area, thereby intensifying heat dissipation. The coils can assume diverse shapes and be arranged in different configurations to optimize cooling efficiency. Moreover, aluminum boasts not only being lightweight but also resistant to corrosion, rendering it a sensible and economical selection for heat sink applications.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: What are the potential applications of color-coated aluminum coils?

- Color-coated aluminum coils have a wide range of potential applications due to their versatility and durability. One of the main uses of these coils is in the construction industry. They can be used for cladding buildings, roofs, and facades, providing an aesthetically pleasing and long-lasting solution. The color coating on the aluminum coils not only adds visual appeal but also protects the metal from corrosion and environmental damage. Another application of color-coated aluminum coils is in the manufacturing of transportation vehicles. These coils can be used for making panels, doors, and other parts of automobiles, trucks, and trailers. The color coating not only enhances the appearance but also offers protection against harsh weather conditions, UV rays, and other external factors. Color-coated aluminum coils are also commonly used in the production of household appliances. They can be used for manufacturing kitchen appliances, such as refrigerators, ovens, and microwave ovens, as well as for creating decorative elements in interior design, such as wall panels, ceilings, and furniture. Furthermore, color-coated aluminum coils find applications in the signage industry. They can be easily shaped, cut, and formed into various sizes and shapes, making them ideal for creating eye-catching signs, billboards, and advertising displays. The color coating ensures that the signs remain vibrant and attractive for an extended period. In addition to these industries, color-coated aluminum coils are also used in the manufacturing of electronic products, such as laptops, smartphones, and tablets. The coils can be used for creating casings, frames, and other parts that require both durability and aesthetic appeal. Overall, the potential applications of color-coated aluminum coils are vast and diverse. Their versatility, durability, and aesthetic appeal make them an excellent choice for various industries, including construction, transportation, household appliances, signage, and electronics.

- Q: What is the purpose of an aluminum coil and what are its applications?

- <p>An aluminum coil is a versatile material that serves various functions. It is used in numerous applications due to its lightweight, corrosion resistance, and high thermal and electrical conductivity. Common uses include manufacturing heat exchangers, transformers, and electrical wiring. Aluminum coils are also utilized in the construction of automotive parts, aerospace components, and in the packaging industry for cans and foils. Additionally, they are employed in the HVAC industry for air conditioning and heating systems, and in the production of various consumer goods.</p>

Send your message to us

Decorative Aluminum Coil for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords