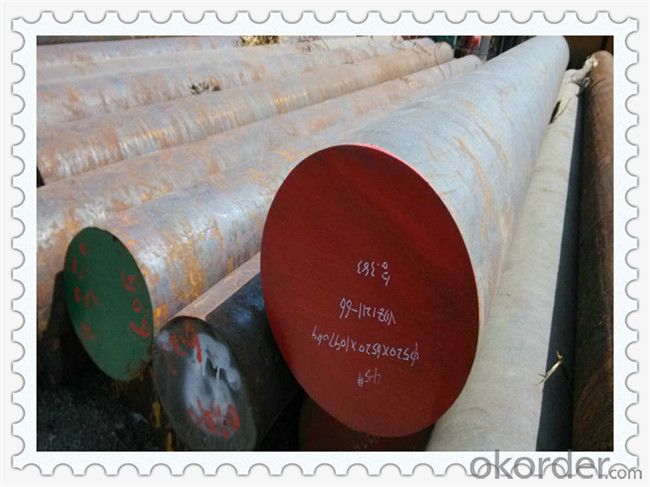

DC53/ Cr8Mo1VSi Forged Tool Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,CE

Thickness:

as required

Length:

as required

Net Weight:

as required

DC53/ Cr8Mo1VSi Forged Tool Steel Round Bar

1. Product Description

| dc53/ Cr8Mo1VSi forged tool steel round bar | |

| feature | 1.chemical composition: C0.9-1.1 Si0.8-1.2 Mn≤0.4 Cr7.5-8.5 Mo1.8-2.2 V0.2-0.5 |

| 2.equivalent grade: GB Cr8Mo1VSi JIS DC53 | |

| 3.technical data: chemical composition,physical properties and mechanical testing as per your demand. | |

| 4.delivery condition: hot rolled or forged, annealed state black/machined/polished surface | |

| 5.dimensions: round bar dia.10-700mm length:2-6m flat bar T:20-500mm W:50-600 L:2-6m | |

6.property and application: good hardness and toughness.it is Usually used as cold work die steel material. and copper, aluminum alloys die casting mold | |

| 7.ultrasonic test: according to SEP1921-84 G3 D/d E/e. | |

| 8.process:EAF+ LF+VD+forging/rolling heat-treatment is optional | |

| packing | seaworthy packing or proper packing as per your requirement |

| sample | 1.hand samples times: within 7-15days |

| 2.samples charge: sample is free according to special grades in stock | |

| 3.samples refund: negotiation | |

| 4.send samples: via TNT,UPS,FedEx,DHL | |

| Payment | T/T,30%deposit, balance paid before shipment. |

| delivery time | within 7-30days according to quantity |

| shipping port | Shanghai Port or China main port |

2. Our Main Products

| Cold work tool steel | |

| AISI | L1 L3 D2 D3 D6 A2 A5 O1 O2 6F7 |

| DIN | 1.2067 1.2080 1.2363 1.2379 1.2436 1.2510 1.2550 1.2746 1.2767 1.2842 |

| JIS | SKD1 SKD11 SKD12 SNCM2 SUJ2 DC53 |

| Hot work tool steel | |

| AISI | H10 H11 H12 H13 H21 L6 |

| DIN | 1.2343 1.2344 1.2365 1.2367 1.2581 1.2714 1.2885 |

| JIS | SKD5 SKD 6 SKD61 SKT4 |

| Plastic mould steel | |

| AISI | 420SS 420H P20 P20+Ni P20+S |

| DIN | 1.2083 1.2085 1.2311 1.2312 1.2316 1.2738 |

| JIS | NAK80 |

| High speed tool steel | |

| T42 M35 M42 T4 T5 M2 M3-2 M1 M7 M4 T1 | |

| Alloy steel/tool steel | |

| AISI | 9840 4340 5140 4135 4140 4145 |

| DIN | 1.6510 1.6511 1.6580 1.6582 1.7035 1.7214 1.7220 1.7225 1.7228 |

- Q: Can steel round bars be used in the agricultural industry?

- Indeed, the agricultural industry can utilize steel round bars. Within this sector, there exists a broad array of applications for them, including the construction of fences, gates, and livestock enclosures. Moreover, steel round bars are frequently employed as support and reinforcement in structures like barns, sheds, and agricultural machinery. Due to their exceptional strength and durability, they are well-suited for enduring the challenging conditions and heavy loads often encountered in agricultural environments. Furthermore, steel round bars can undergo further processing and fabrication, resulting in an assortment of agricultural tools and equipment, such as hitches, plows, and cultivators. In summary, steel round bars represent a versatile and dependable material capable of effectively satisfying the agricultural industry's requirements.

- Q: How do you calculate the weight of a steel round bar based on its length and volume?

- To calculate the weight of a steel round bar based on its length and volume, you need to know the density of the steel. The density represents the amount of mass per unit volume of the material. The formula to calculate the weight is: Weight = Volume × Density First, you need to calculate the volume of the steel round bar. The volume of a cylinder (which is the shape of a round bar) is given by the formula: Volume = π × (Radius)^2 × Length Where π is a mathematical constant approximately equal to 3.14, and Radius is the radius of the round bar. Once you have the volume, you can multiply it by the density of the steel to find the weight. The density of steel can vary depending on the specific type of steel being used. For example, the density of mild steel is around 7850 kg/m³. Therefore, the weight of the steel round bar is calculated as: Weight = Volume × Density For example, let's say we have a steel round bar with a length of 1 meter and a radius of 0.5 meters. To calculate the weight, we need to find the volume first: Volume = π × (0.5)^2 × 1 Volume = 0.7854 m³ Next, we multiply the volume by the density of steel: Weight = 0.7854 m³ × 7850 kg/m³ Weight = 6171.79 kg So, the weight of the steel round bar would be approximately 6171.79 kg.

- Q: What are the different methods of cutting steel round bars?

- There are several methods for cutting steel round bars, each with its own advantages and limitations. Some of the most commonly used methods include: 1. Abrasive cutting: This method involves using a rotating abrasive wheel to grind through the steel round bar. It is a fast and efficient method, but it can produce a rough cut surface and generate a significant amount of heat. 2. Bandsaw cutting: Bandsaw machines are commonly used to cut steel round bars. They consist of a continuous band of toothed metal that rotates around two wheels, slicing through the material. Bandsaws provide a smooth and precise cut, but they are slower than some other methods. 3. Cold saw cutting: Cold saws are specifically designed for cutting metal, including steel round bars. They use a circular saw blade with teeth that have been specially designed to withstand the hardness of steel. Cold saws produce clean and accurate cuts, but they are generally slower than abrasive or bandsaw cutting. 4. Plasma cutting: Plasma cutting is a high-energy cutting method that uses a focused jet of ionized gas to melt and remove the metal. It is commonly used for thicker steel round bars and can produce a precise and clean cut. However, it requires specialized equipment and can be more expensive than other methods. 5. Laser cutting: Laser cutting uses a high-powered laser beam to melt and vaporize the metal, resulting in a precise and clean cut. It is a versatile method that can be used for various thicknesses of steel round bars. However, it requires expensive equipment and may not be suitable for all applications. Ultimately, the choice of cutting method depends on factors such as the thickness and hardness of the steel round bar, the desired cut quality, the available equipment, and the specific requirements of the project.

- Q: What are the different types of surface defects that can occur in steel round bars?

- Steel round bars can experience multiple types of surface defects. Some of the most frequently encountered defects include the following: 1. Scratches: These shallow grooves or marks on the round bar's surface occur due to friction or contact with sharp objects during handling or transportation. 2. Pitting: Small, localized cavities or depressions on the surface are caused by corrosion or exposure to harsh environments. If left unaddressed, pitting can lead to further corrosion. 3. Scale: During the manufacturing process, a thin layer of oxide or impurities, known as scale, can form on the surface of steel round bars. Although it affects appearance and quality, scale is often removed during subsequent processing or cleaning. 4. Scabs: Irregularly shaped protrusions or raised areas on the surface result from solidification or cooling issues during the casting process. Proper attention is required to ensure the strength and integrity of the bar. 5. Roll marks: Elongated depressions or ridges on the surface are caused by uneven or improper rolling during manufacturing. Roll marks can impact the dimensional accuracy of the bar and may necessitate additional processing or grinding for removal. 6. Laminations: Sometimes visible on the surface, laminations are internal defects resulting from improper bonding or separation of layers during the steelmaking process. They can weaken the bar and reduce its load-bearing capacity. 7. Inclusions: Non-metallic particles or impurities can become trapped in the steel during manufacturing, appearing as dark spots or irregularities on the round bar's surface. Inclusions can affect the bar's mechanical properties. It is essential to recognize that the severity and impact of these surface defects may vary. Manufacturers and quality control personnel employ diverse inspection techniques to identify and mitigate these defects, ensuring the quality and reliability of the final product.

- Q: Are steel round bars prone to fatigue failure?

- Fatigue failure is a common occurrence in steel round bars, which can be attributed to repeated cyclic loading or stress. This leads to a gradual weakening of the material, eventually causing it to fail, even if the applied stress is below its ultimate strength. Due to their inherent characteristics, steel round bars, like other structural materials, are susceptible to fatigue failure. Various factors can contribute to fatigue failure in steel round bars, including improper design, inadequate material selection, manufacturing defects, and excessive cyclic loading. Additionally, surface defects, notches, stress concentrations, and corrosive environments can further accelerate the fatigue process. Engineers and designers take several measures to mitigate the risk of fatigue failure. These include implementing appropriate design practices, selecting high-quality materials, conducting thorough inspections, applying stress-relieving treatments, and considering the impact of cyclic loading during the structural design phase. It is important to understand that the susceptibility of steel round bars to fatigue failure depends on multiple factors, such as the specific steel grade, loading conditions, environmental factors, and overall structural design. Therefore, it is crucial to carefully assess these factors and employ appropriate mitigation measures to ensure the safe and reliable performance of steel round bars in various applications.

- Q: Can steel round bars be used for making turbine blades?

- Using steel round bars to make turbine blades is not possible. Turbine blades experience high temperatures and extreme forces, so they need to be durable and flexible. Steel round bars do not have the required properties to endure these conditions. Usually, turbine blades are constructed from materials like titanium alloys or advanced composites, which have a high strength-to-weight ratio, exceptional fatigue resistance, and thermal stability. These materials are purposely designed to withstand the challenging conditions of turbine operations, ensuring efficiency and reliability.

- Q: How are steel round bars used in the manufacturing of hydraulic cylinders?

- Steel round bars are a crucial component in the manufacturing of hydraulic cylinders due to their strength, durability, and versatility. These round bars are typically made from carbon steel, alloy steel, or stainless steel, which are all known for their high tensile strength and resistance to corrosion. The first step in using steel round bars for hydraulic cylinders is the selection of the appropriate diameter and length. The diameter of the round bar determines the overall strength of the hydraulic cylinder, and the length determines its size and capacity. Once the desired dimensions are determined, the steel round bars are cut to the required length using specialized cutting tools. Next, the steel round bars undergo a series of processes to shape them into the necessary components of a hydraulic cylinder. This includes machining, drilling, and turning operations to create features such as threaded ends, grooves, and mounting surfaces. These processes are carried out with precision to ensure the round bars meet the exact specifications of the hydraulic cylinder design. After the shaping processes, the steel round bars are heat-treated to enhance their mechanical properties. Heat treatment involves heating the round bars to a specific temperature and then rapidly cooling them to achieve the desired hardness, toughness, and dimensional stability. This step is crucial in ensuring the hydraulic cylinders can withstand the high pressures and forces they will encounter during operation. Once the steel round bars have been shaped and heat-treated, they are further processed to achieve the desired surface finish. This can involve processes such as grinding, polishing, or coating to improve the round bars' appearance and resistance to corrosion. The surface finish is important for ensuring smooth operation and preventing any potential leaks or damage to the hydraulic cylinder. Finally, the steel round bars are assembled with other components such as piston rods, cylinder heads, and seals to complete the hydraulic cylinder. These assemblies are carried out using advanced welding or fastening techniques to ensure the components are securely attached and can withstand the forces and pressures exerted during hydraulic operation. In summary, steel round bars play a vital role in the manufacturing of hydraulic cylinders by providing the necessary strength, durability, and versatility required for these critical components. From the initial selection of the appropriate diameter and length to the shaping, heat treatment, and assembly processes, the use of steel round bars ensures the hydraulic cylinders can effectively transmit hydraulic power while withstanding the demanding conditions they are designed for.

- Q: What is the difference between 40Cr round steel and 40Cr steel forgings?

- Generally speaking the 40Cr steel is a kind of hot rolled steel (rarely cold). The need for heating the material before hot rolling process is or rolled, usually heated to above the recrystallization temperature, then condensation formed after the bar, of course I say is very simple, there are many steps.

- Q: Can steel round bars be used in the construction of buildings?

- Indeed, the utilization of steel round bars is viable in the erection of edifices. In the realm of construction, steel round bars are widely employed as reinforcement within concrete frameworks, specifically in columns, beams, and slabs. Their inclusion imparts heightened robustness and stability to the structure, augmenting its resilience against various loads and forces. Notably, the circular configuration of these bars facilitates effortless bending and molding, thereby rendering them versatile and adaptable for diverse construction applications. What's more, steel round bars are renowned for their exceptional tensile strength, durability, and resistance to corrosion, rendering them an optimal choice for enduring and dependable building construction projects.

- Q: Can steel round bars be used in the production of gears?

- Indeed, gears can be produced using steel round bars. The utilization of steel round bars as a primary material in the production of gears is quite common due to their remarkable strength, endurance, and capacity to endure substantial loads and extreme temperatures. These round bars can be either machined or forged into the desired gear configuration, guaranteeing precise measurements and precise tooth profiles. Additionally, steel round bars exhibit exceptional resistance to wear and can be subjected to heat treatment to further augment their mechanical qualities. Consequently, they are a suitable option for an array of gear types, encompassing spur gears, helical gears, bevel gears, and worm gears.

Send your message to us

DC53/ Cr8Mo1VSi Forged Tool Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords