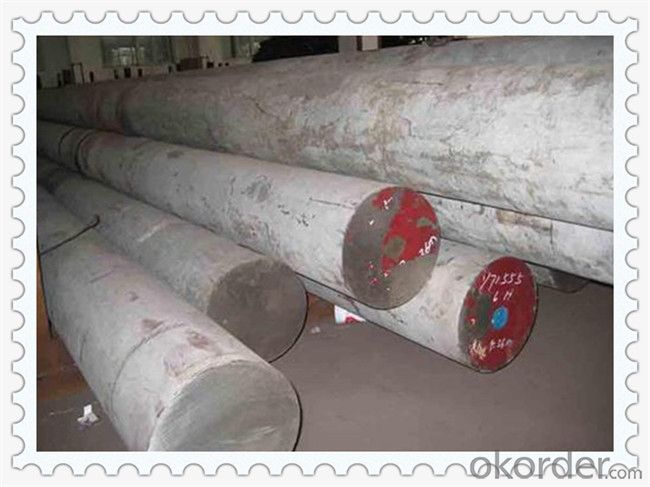

Forged Alloy Tool Steel Round Bar A8

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,CE

Thickness:

as required

Length:

as required

Net Weight:

as required

AISI A8 / 5Cr5WMoVSi Special Tool Steel Round Bar

Chemical Composition(%) | ||||||

| C | Si | Mn | P | S | Cr | Mo |

| 0.5-0.6 | 0.75-1.10 | 0.2-0.50 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.15-1.65 |

| Specialty | ||||||

Special alloy steel, engineering steel supplied in quenched and tempered conditions. Very good machinability.High toughness. High creep strength. Repeated impact resistant capability. | ||||||

| Use | ||||||

Components with high requirements on toughness, e.g.gear wheels, pinions, connecting rods, parts for mechanical engineering. | ||||||

| Heat Treatment | ||||||

| Annealed to max. 241 HB | ||||||

| Melting Process | ||||||

| 1. EAF: Electric Furnace+LF+VD(Optional) | ||||||

| 2. ESR: Electric Furnace+LF+VD+Eleroslag Remelted(Optional) | ||||||

| UT Class | ||||||

| According to Standard of SEP 1921/84,100% Volume, Level C/c, D/d or E/e | ||||||

| Tolerance on Quantity | ||||||

| +/-10% Per Size | ||||||

- Q: Are steel round bars susceptible to cracking?

- Yes, steel round bars can be susceptible to cracking under certain conditions. Cracking can occur due to factors such as excessive stress, improper handling, or poor manufacturing processes. However, the susceptibility to cracking can be minimized by using high-quality steel, proper heat treatment, and careful handling and installation techniques.

- Q: What is the cost of steel round bars compared to other materials?

- The cost of steel round bars can vary depending on the specific type of steel and current market conditions. Generally, steel round bars tend to be more cost-effective compared to other materials such as aluminum or titanium, especially when considering their strength and durability. However, it is always recommended to compare prices and quality from different suppliers to get a more accurate understanding of the cost differences.

- Q: Can steel round bars be used in the manufacturing of heat exchangers?

- Heat exchangers can indeed utilize steel round bars in their manufacturing process. Due to its exceptional strength and thermal conductivity, steel is frequently employed in the construction of heat exchangers. By shaping and welding steel round bars, a range of sizes and forms can be achieved, enabling the creation of crucial heat exchanger elements like tubes, headers, and baffles. Furthermore, the durability and corrosion resistance of steel make it an ideal choice for numerous industrial applications that demand efficient heat transfer.

- Q: What is the difference between a hot-finished and a cold-finished steel round bar?

- The main difference between a hot-finished and a cold-finished steel round bar lies in the manufacturing process and the resulting physical properties of the steel. Hot-finished steel round bars are produced by passing the steel through a high-temperature furnace, followed by a series of rolling processes. This process helps to shape the steel into its desired final dimensions. The high temperatures during the manufacturing process allow for the steel to be more malleable, making it easier to shape and form. As a result, hot-finished steel round bars often have a rougher surface finish and may have slight imperfections such as scaling and decarburization. However, the high-temperature process imparts improved mechanical properties to the steel, such as higher tensile strength and yield strength, making it suitable for applications that require higher strength and durability. On the other hand, cold-finished steel round bars undergo a different manufacturing process. Cold-finished bars are formed by passing the steel through a series of cold rolling processes, which typically occur at room temperature. This process results in a smoother surface finish and tighter dimensional tolerances compared to hot-finished bars. The absence of high temperatures during the manufacturing process prevents scaling and decarburization, resulting in a more uniform and clean appearance. While cold-finished bars may have slightly lower tensile strength and yield strength compared to hot-finished bars, they offer improved dimensional accuracy and a smoother surface, making them suitable for applications that require precision machining or aesthetic appeal. In summary, the main differences between hot-finished and cold-finished steel round bars lie in the manufacturing process, surface finish, dimensional accuracy, and mechanical properties. Hot-finished bars offer higher strength and are suitable for applications that prioritize durability, while cold-finished bars provide better surface finish and dimensional accuracy, making them ideal for precision machining or applications where aesthetics are important.

- Q: How do steel round bars perform under fatigue loading?

- High-quality steel round bars generally exhibit excellent performance when subjected to fatigue loading. Fatigue loading refers to the repetitive application of stress or strain on a material, which can eventually cause failure. The outstanding fatigue strength of steel round bars is well-known. This refers to their ability to withstand cyclic loading without developing cracks or failures. This exceptional fatigue strength can be attributed to the inherent properties of steel, including its high strength, ductility, and toughness. During fatigue loading, steel round bars undergo cyclic stress, resulting in alternating tension and compression. Nonetheless, steel possesses a relatively high endurance limit, also known as the fatigue strength coefficient. This limit determines the maximum stress level that the material can endure without failure, even under cyclic loading. Moreover, steel round bars demonstrate commendable resistance to fatigue crack propagation. In the event that a crack does initiate due to cyclic loading, it is less likely to propagate or grow rapidly in comparison to other materials. This can be attributed to the material's ability to absorb energy and redistribute stress, thus impeding crack growth and preventing failure. Nevertheless, it is essential to consider that the performance of steel round bars under fatigue loading can be influenced by various factors. These factors include the specific type and grade of steel utilized, the manufacturing process, surface conditions, and the applied stress or strain levels. Therefore, it is crucial to adhere to industry standards and guidelines when designing and implementing steel round bars to ensure optimal performance and safety under fatigue loading.

- Q: Are steel round bars suitable for use in the oil and gas industry?

- Steel round bars are well-suited for the oil and gas industry due to their strength, durability, and high resistance to corrosion. They can withstand the challenging and harsh environments encountered in this industry, making them reliable for critical components such as drilling tools, valves, pipelines, and offshore structures. In the oil and gas industry, extreme temperatures, pressures, and corrosive substances are present in offshore rigs, refining facilities, and pipelines. Steel round bars can withstand these conditions and maintain their structural integrity, making them a reliable choice for critical components. Steel round bars also offer versatility as they can be easily machined, welded, and fabricated into different shapes and sizes. This flexibility is crucial in the oil and gas industry, which often requires unique and complex equipment. Moreover, steel round bars possess excellent mechanical properties such as high tensile strength and impact resistance. These properties are essential for withstanding heavy loads and dynamic forces associated with oil and gas operations, ensuring the safety and reliability of equipment and structures. Additionally, steel round bars have a high resistance to corrosion, which is vital in the oil and gas industry due to the presence of corrosive substances like hydrogen sulfide and saltwater. This corrosion resistance ensures the longevity and reliability of equipment, reducing maintenance costs and downtime. In conclusion, steel round bars are a suitable choice for the oil and gas industry due to their strength, durability, corrosion resistance, and versatility. They are ideal for various applications, ensuring the safe and efficient operation of equipment and structures in this demanding industry.

- Q: How many meters is the minimum loading surface of galvanized steel wire for grounding grid?

- Round steel (grade 1 steel) belongs to ordinary low carbon steel with low strength. However, the plasticity of the round bar is stronger, that is, the round steel has a larger deformation before it is pulled off.It has been widely used in the fields of hardware, construction, automobile, shipbuilding, petrochemical, machinery, medicine, food, electricity, energy, space, etc.. The most extensive machining of general machine parts, general rod type steel parts, CD pole, bolt, nut.

- Q: What are the advantages of using niobium-alloy steel round bars?

- There are several advantages of using niobium-alloy steel round bars. Firstly, niobium improves the strength and toughness of the steel, making it highly durable and resistant to fatigue and wear. Secondly, the alloy's high temperature stability allows for its use in extreme conditions without compromising its structural integrity. Additionally, niobium-alloy steel round bars offer excellent corrosion resistance, making them suitable for applications in harsh environments. Lastly, the alloy's lightweight nature makes it ideal for industries that require strong yet lightweight materials, such as aerospace and automotive sectors.

- Q: What are the limitations of using steel round bars?

- Using steel round bars in various applications has several limitations. One such limitation is their vulnerability to corrosion. Steel round bars, particularly those made of carbon steel, are prone to rusting when exposed to moisture or harsh environments. This can have a significant impact on their structural integrity and lifespan. Another limitation is their weight. Steel is a heavy material, and round bars can be especially cumbersome to handle and transport, especially in large quantities. This can make the installation process more difficult and increase the overall project cost. In addition, steel round bars may not be suitable for applications that require high levels of flexibility or bending. Their rigid nature makes it challenging to shape or mold them into intricate designs. This limitation can restrict their use in certain industries or architectural designs that demand more versatile materials. Another factor to consider is the cost of steel round bars. Depending on the grade, quality, and market conditions, the price of steel round bars can fluctuate significantly. This can be a financial limitation for projects with tight budgets or when the cost of raw materials is a crucial factor. Lastly, steel round bars may not be suitable for applications that require high resistance to extreme temperatures. While steel has good thermal conductivity, certain temperature ranges can affect its structural properties, potentially causing weaknesses or deformations. Overall, steel round bars have widespread use and offer many advantages. However, it is essential to consider their limitations such as susceptibility to corrosion, weight, limited flexibility, cost, and temperature sensitivity when selecting materials for specific applications.

- Q: How do you prevent warping of steel round bars during machining?

- There are several measures that can be taken to prevent warping of steel round bars during machining. These measures include: 1. Opting for the appropriate steel material with suitable mechanical properties is crucial. Choosing steel with lower carbon content and controlled alloying elements can help decrease the likelihood of warping during machining. 2. Before machining, it is important to conduct a stress relief process such as annealing or normalizing. This helps eliminate internal stresses in the steel round bars, thereby minimizing warping. 3. Utilizing proper machining techniques is essential in preventing warping. This involves using a stable and rigid machine setup, ensuring correct tool geometry and sharpness, and maintaining appropriate cutting speeds and feeds. Monitoring cutting forces and temperatures continuously can also assist in identifying any abnormal conditions that may contribute to warping. 4. Excessive heat generated during machining can cause localized expansion and lead to warping. To prevent this, it is recommended to use coolant or lubricant to dissipate heat and reduce friction between the tool and the workpiece. Sufficient cooling helps maintain a stable temperature and prevents warping. 5. When machining long steel round bars, it is advisable to use appropriate fixtures or supports to prevent excessive deflection or bending. This ensures that the bar remains straight and stable during machining, reducing the chances of warping. 6. Even after machining, stress can still be present in the steel round bars. Performing a post-machining stress relief process, such as tempering or normalization, can further alleviate any residual stresses and minimize the risk of warping. By implementing these measures, the risk of warping during the machining of steel round bars can be significantly reduced. This leads to improved dimensional accuracy and overall quality of the machined parts.

Send your message to us

Forged Alloy Tool Steel Round Bar A8

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords